Preparation method and application of highly selective chlorsulfuron magnetic molecularly imprinted polymer

A magnetic molecular imprinting, high-selectivity technology, applied in chemical instruments and methods, analytical materials, material separation, etc., can solve the problems of incomplete removal of templates, poor accessibility of imprinting sites, and large diffusion resistance, etc., to achieve efficient separation And enrichment, fast desorption rate, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

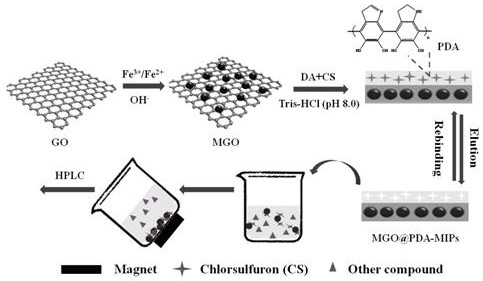

[0053] Preparation of Chlorsulfuron Magnetic Molecularly Imprinted Polymer

[0054] (1) Preparation of graphene oxide (GO) by improved Hummer method

[0055] 5g graphite powder, 300mL sulfuric acid, 4.2g K 2 S 2 o 8 and 6.2g P 2 o 5 Add them to a 500mL flask in turn, put them in a water bath at 80°C for 5h, after cooling to room temperature, rinse the mixture with water, vacuum filter, and dry at room temperature for 2 days.

[0056] Add the above pre-oxidized graphite to 200mL of concentrated sulfuric acid at 0°C, and add 15g of KMnO under slow stirring 4 , stirred in a water bath at 35 °C for 2 h, washed the mixture with water, and then added 10 mL of 30% H 2 o 2 , let it stand for 2 days, pour out the supernatant, wash with 0.1mol / L hydrochloric acid and water for several times, and vacuum-dry the precipitate at 65°C for 1-2 days to obtain graphene oxide flake material, which can be obtained after grinding. graphene oxide.

[0057] (2) Preparation of Magnetic Graph...

Embodiment 2

[0064] Characterization of Chlorsulfuron Magnetic Molecularly Imprinted Polymer

[0065] (1) Adsorption kinetics experiment

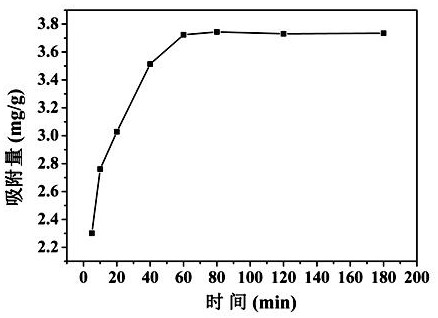

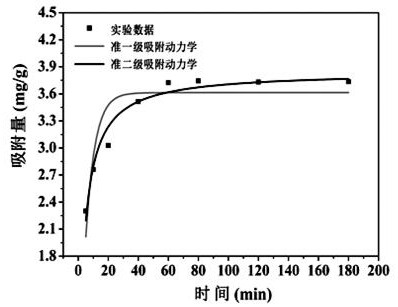

[0066] In order to investigate the adsorption capacity of the prepared chlorsulfuron magnetic molecularly imprinted polymer on the target at different adsorption times, accurately weigh 20 mg of the imprinted polymer into a brown volumetric flask, add 10 mL of chlorsulfuron-methyl- Acetonitrile standard solution, shake at room temperature for 5min, 10min, 20min, 40min, 60min, 80min, 120min, 180min respectively, use a magnet to separate the polymer material, take the supernatant and filter it through a 0.45μm filter membrane, and measure the adsorption by HPLC The concentration of the solution, the detection wavelength is 235nm. The result is as figure 2 , it can be seen from the figure that after 60 min of adsorption, the adsorption equilibrium is reached.

[0067] It can be known from experiments that the lower the concentration of chlorsulfuron, t...

Embodiment 3

[0094] The specific cases of applying the chlorsulfuron magnetic molecularly imprinted polymer in Example 1 to the determination of sulfonylurea herbicide residues in rice, soybean and wheat are as follows:

[0095] (1) Sample extraction

[0096] Weigh 10 g of pulverized samples, add 30 mL of acetonitrile to shake for 10 min, centrifuge at 4000 r / min for 5 min, and collect the supernatant. Repeat the extraction process twice, combine the extracts in a separatory funnel, add 20mL of acetonitrile-saturated n-hexane solution, shake for 2min, let stand to separate and collect the extracts from the lower sample. Blow dry at 40°C with nitrogen and redissolve with 10 mL of acetonitrile.

[0097] (2) Magnetic matrix solid phase extraction

[0098] Weigh 20 mg of the magnetic molecularly imprinted polymer material obtained in Example 1 into a brown volumetric flask, add the above-mentioned sample extract, shake for 60 min, separate the extract by using an external magnetic field, rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com