Blue-phase liquid-crystal composite material and liquid crystal display containing same

A technology of blue-phase liquid crystal and composite materials, which is applied in liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of small Cole coefficient and large Cole coefficient of blue-phase liquid crystal composite materials, and achieve the reduction of saturation voltage and the reduction of electric field The effect of fast response and low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a blue-phase liquid crystal composite material. The blue-phase liquid crystal composite material is formed by photopolymerization of raw material components. Polymerizable monomers, photoinitiators.

[0055] Wherein, the benzyne species has the following structural formula,

[0056]

[0057] where: R 1 The structural formula of is shown in the following formula,

[0058]

[0059] Among them, the value of n is 2; R 2 is a hydrogen group; R 3 is a hydrogen group; R 4 For cyano.

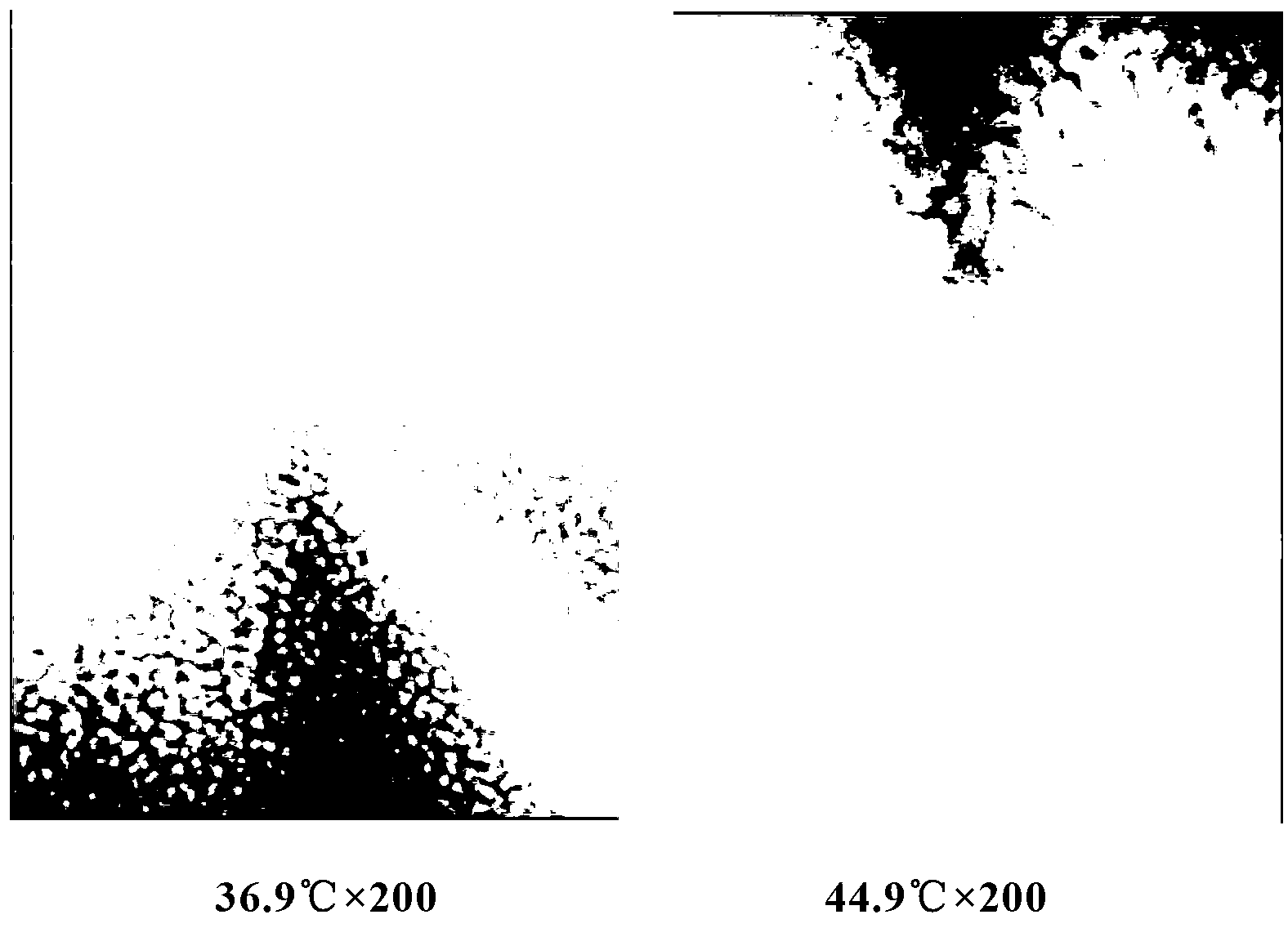

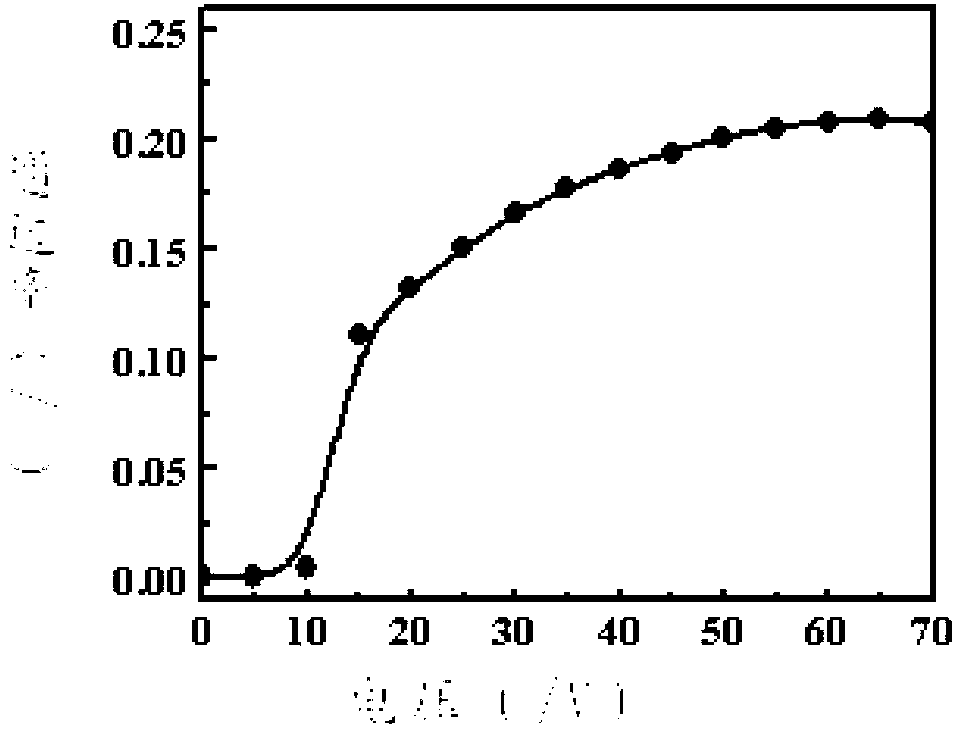

[0060]The parent blue phase liquid crystal is SLC-X (Yongsheng Huatsing Liquid Crystal Co., Ltd, Δn=0.253, Δε=29.6, at298K), and its main components include biphenyl nitrile liquid crystal (biphenyl alkyl nitrile liquid crystal or biphenyl alkoxy Nitrile-based liquid crystal) and fluorine-containing small molecule liquid crystal; the viscosity of the parent blue phase liquid crystal is less than 50mPa, the melting point is lower than -40°C, and the clearing po...

Embodiment 2

[0070] This embodiment provides a blue-phase liquid crystal composite material. The blue-phase liquid crystal composite material is formed by photopolymerization of raw material components. Polymerizable monomers, photoinitiators.

[0071] Wherein, the structural formula of benzynes is shown in the following formula,

[0072]

[0073] Wherein: R1 structural formula is as shown in the following formula,

[0074]

[0075] Among them, the value of n is 4; R 2 is a fluorine group; R 3 is a hydrogen group; R 4 For cyano.

[0076] The parent blue phase liquid crystal is SLC-X (Yongsheng Huatsing Liquid Crystal Co., Ltd, Δn=0.253, Δε=29.6, at298K), and its main components include biphenyl nitrile liquid crystal (biphenyl alkyl nitrile liquid crystal or biphenyl alkoxy Nitrile-based liquid crystal) and fluorine-containing small molecule liquid crystal; the viscosity of the parent blue phase liquid crystal is less than 50mPa, the melting point is lower than -40°C, and the cl...

Embodiment 3

[0086] This embodiment provides a blue-phase liquid crystal composite material. The blue-phase liquid crystal composite material is formed by photopolymerization of raw material components. Polymerizable monomers, photoinitiators.

[0087] Wherein, the structural formula of benzynes is shown in the following formula,

[0088]

[0089] Wherein: R1 structural formula is as follows,

[0090]

[0091] Among them, the value of n is 12; R 2 is a fluorine group; R 3 is a fluorine group; R 4 For cyano.

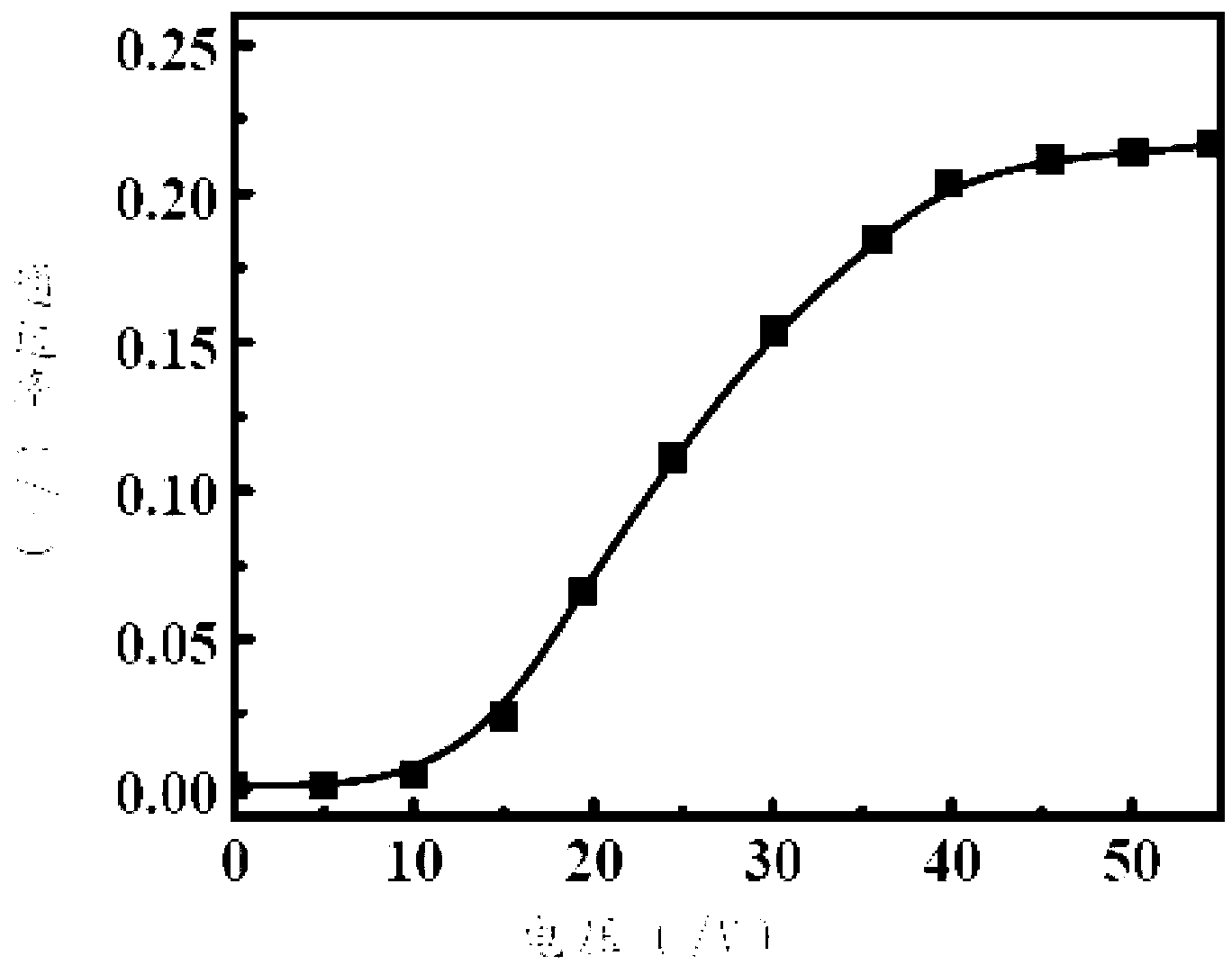

[0092] The parent blue phase liquid crystal is SLC-X (Yongsheng Huatsing Liquid Crystal Co., Ltd, Δn=0.253, Δε=29.6, at298K), and its main components include biphenyl nitrile liquid crystal (biphenyl alkyl nitrile liquid crystal or biphenyl alkoxy Nitrile-based liquid crystal) and fluorine-containing small molecule liquid crystal; the viscosity of the parent blue phase liquid crystal is less than 50mPa, the melting point is lower than -40°C, and the clearing point is betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Clear point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com