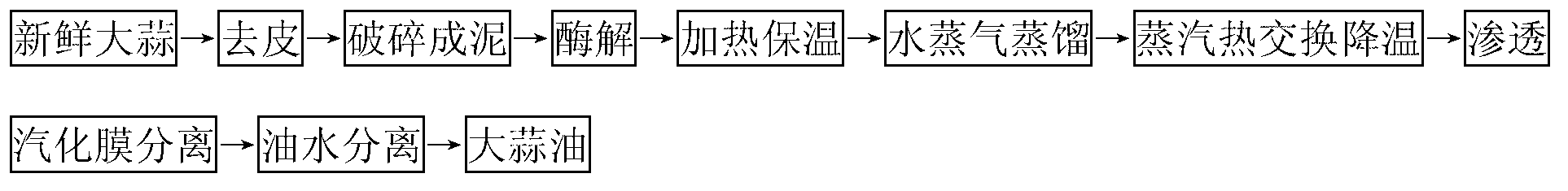

Separation and extraction method of garlic oil

An extraction method and garlic oil technology, which are applied in the directions of edible oil/fat, tallow oil/fat production, tallow oil/fat refining, etc., to achieve the effects of low energy consumption and mild separation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Fresh garlic is peeled, cleaned, and crushed into garlic paste, and water is added. The mass ratio of garlic to water is 1:2. After constant temperature enzymolysis at 40°C for 3 hours, keep it at 70°C for 90 minutes, and steam distill the obtained mixture for 3 hours. The condenser condenses to obtain an oil-water mixture. The oil-water mixture is subjected to microfiltration, the pore size of the microfiltration membrane is 10 μm, and the transmembrane pressure is 0.5 MPa. The emulsion on the permeation side obtained by microfiltration was placed in the feed liquid bottle of the pervaporation device, and the feed liquid bottle was placed in a collector type magnetic stirrer for heating in a 60°C constant temperature water bath with a flow rate of 0.32 L / min. The downstream pressure in the pervaporation device is 3mm Hg, the pervaporation time is 3h, and the membrane material used is PDMS / alumina ceramic composite membrane. After collecting the product in the condensa...

Embodiment 2

[0031] Fresh garlic is peeled, cleaned, and crushed into garlic paste, then add water, the mass ratio of garlic to water is 1:4, after constant temperature enzymolysis at 30°C for 1 hour, keep it warm at 90°C for 30 minutes, steam distill the obtained mixture for 3 hours, and The condenser condenses to obtain an oil-water mixture. The oil-water mixture is subjected to microfiltration, the pore size of the microfiltration membrane is 5 μm, and the transmembrane pressure is 0.1 MPa. The emulsion on the permeation side obtained by microfiltration was placed in the feed liquid bottle of the pervaporation device, and the feed liquid bottle was placed in a collector type magnetic stirrer for heating in a 50°C constant temperature water bath with a flow rate of 0.48 L / min. The downstream pressure in the pervaporation device is 3mm Hg, the pervaporation time is 6h, and the membrane material used is POMS / zirconia ceramic composite membrane. After collecting the product in the condensa...

Embodiment 3

[0033]Fresh garlic is peeled, cleaned, and crushed into garlic paste, then add water, the mass ratio of garlic to water is 1:8, after constant temperature enzymolysis at 20°C for 2 hours, keep it at 80°C for 90 minutes, steam distill the obtained mixture for 2 hours, The condenser condenses to obtain an oil-water mixture. The oil-water mixture is subjected to microfiltration, the pore size of the microfiltration membrane is 0.025 μm, and the transmembrane pressure is 0.3 MPa. The emulsion on the permeation side obtained by microfiltration was placed in the feed liquid bottle of the pervaporation device, and the feed liquid bottle was placed in a collector magnetic stirrer for heating in a 30°C constant temperature water bath with a flow rate of 0.40 L / min. The downstream pressure in the pervaporation device is 15mm Hg, the pervaporation time is 5h, and the membrane material used is PEBA / titanium oxide ceramic composite membrane. After collecting the product in the condensatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com