Preparation method of lambda-carrageenan oligosaccharide

A technology of carrageenan oligosaccharides and carrageenan, which is applied in the field of preparation of λ-carrageenan oligosaccharides, can solve the problems of irregular cutting, environmental pollution, complex process, etc., so as to omit the enzyme preparation process, reduce production costs, optimize The effect of the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

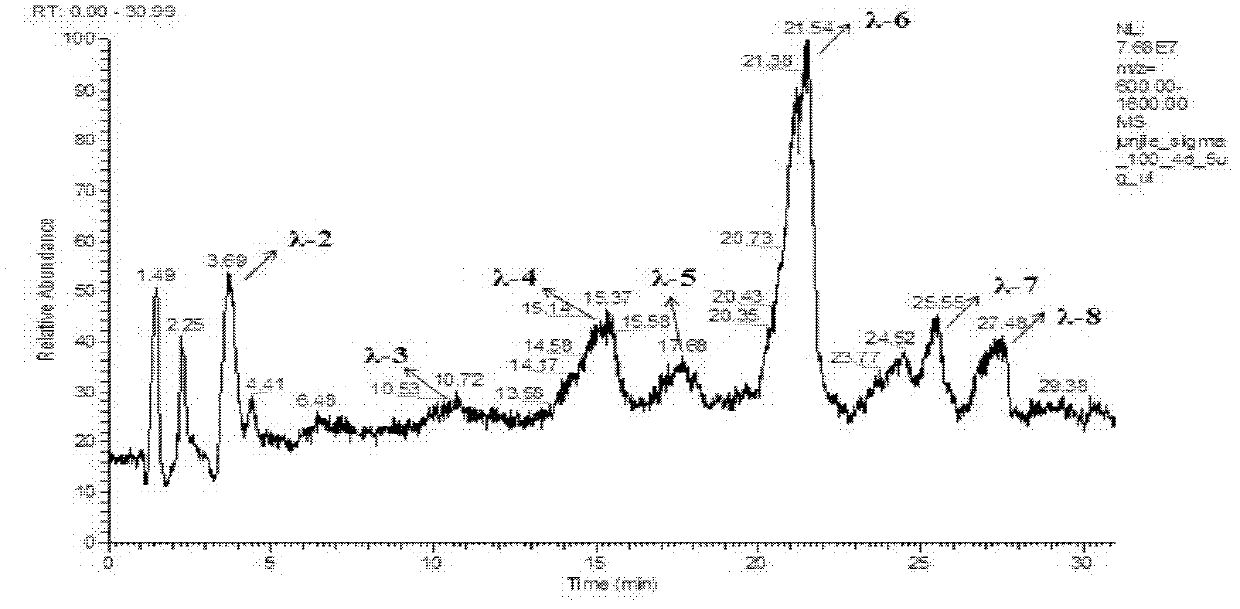

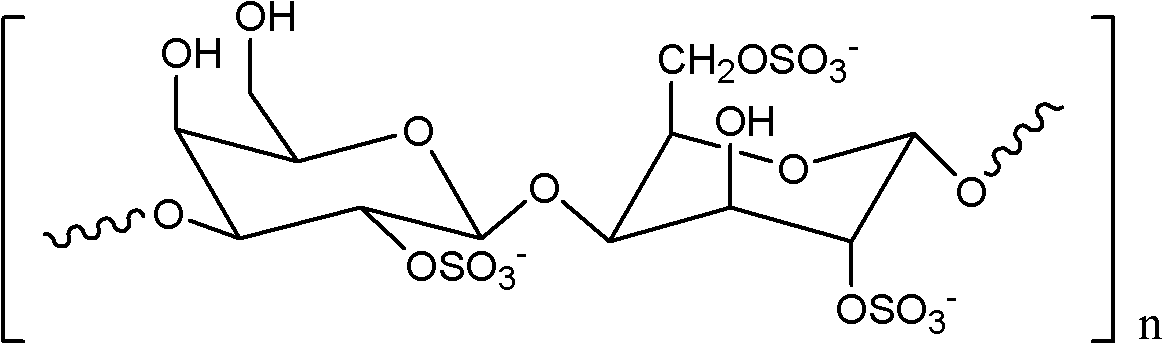

Image

Examples

Embodiment 1

[0024] Prepare ATCC medium 1575 solid medium and 120mL liquid medium. The λ-carrageenan-degrading bacterium Pseudoalteromonas carrageenovora was cultured on a slant at 22°C for 1 day, and the slant bacteria were inoculated into 50 mL of liquid medium, and cultured at 130 rpm at 22°C for 2 days, and an equal volume of sterile 1.5% λ-carrageenan (Wako Pure Industry Co., Ltd. Co., Ltd.) in the reaction medium, 30°C, 130rpm reaction for 2d, 10000rpm centrifugation for 30min, the supernatant was collected, 2 times the volume of washed activated carbon was installed in a 2.6×30cm chromatographic column, and the sugar solution was directly chromatographically The column was adsorbed for 5 hours, and impurities such as unadsorbed oligosaccharides and salts were eluted with pure water, and then eluted with 30% ethanol to obtain an eluate containing λ-carrageenan oligosaccharides with a low degree of polymerization. Concentrate in vacuo and freeze-dry to obtain a white powder λ-carragee...

Embodiment 2

[0026] Prepare ATCC medium 1575 solid medium and liquid medium, and sterilize. The λ-carrageenan-degrading bacteria Pseudoalteromonas carrageenovora was cultured on a slant at 22°C for 1 day, inoculated into 20mL liquid medium, cultured at 22°C and 130rpm for 1d, and expanded step by step until it was placed in a 30L fermenter, and the medium in the tank was ATCC medium 1575 liquid Medium, the inoculum amount is 2%, culture at 22°C, 130rpm for 2 days, add an equal volume of reaction medium containing 2.0% λ-carrageenan, react at 30°C, 130rpm for 4 days, plate filter, collect the filtrate, wash 2 times the volume The activated carbon is installed in a 1×2m chromatographic column, the sugar solution is directly adsorbed on the chromatographic column for 5 hours, the unadsorbed oligosaccharides and salts and other impurities are eluted with pure water, and then eluted with 40% ethanol to obtain The eluate containing λ-carrageenan oligosaccharides with a low degree of polymerizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com