Preparation method of three-dimensional nano porous tin-base alloy for lithium-ion battery negative electrode

A lithium-ion battery, three-dimensional nanotechnology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as limiting the commercial application of tin-based alloys, and achieve the effects of overcoming preparation problems, being environmentally friendly, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) At 25°C, mix and react 0.6 mol / liter aqueous solution of nickel potassium cyanide and 0.6 mol / liter aqueous solution of tin tetrachloride to form a tin-nickel cyanide rubber system, in which potassium nickel cyanide and tin tetrachloride The molar ratio is 0.5:1.

[0025] (2) Take the tin-nickel cyanide rubber system obtained in step (1) as a precursor, add excessive reducing agent sodium borohydride therein, leave it to stand for 1 hour to fully react the tin-nickel cyanide rubber and the reducing agent, wash the product, and then Dry under vacuum to obtain a three-dimensional nanoporous tin-nickel alloy.

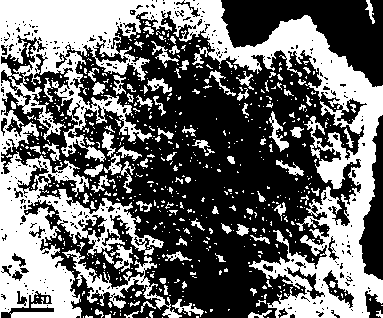

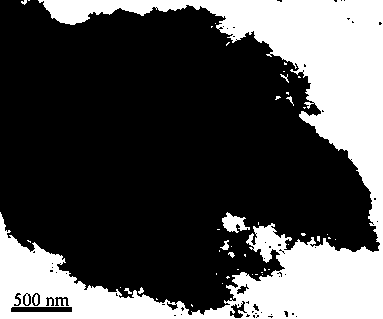

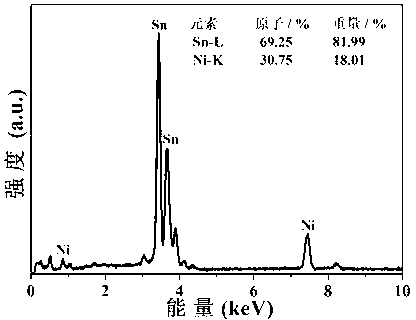

[0026] figure 1 , figure 2 , image 3 and Figure 4 They are the scanning electron micrographs, transmission electron micrographs, energy spectra and electrochemical performance diagrams of the three-dimensional nanoporous tin-nickel alloy synthesized in this example, respectively.

[0027] image 3 is the energy spectrum of the three-dimensional nanoporo...

Embodiment 2

[0029] (1) At 0°C, mix and react 1 mol / liter aqueous solution of nickel potassium cyanide and 1 mol / liter aqueous solution of tin tetrachloride to form a tin-nickel cyanide rubber system, in which nickel potassium cyanide and tin tetrachloride The molar ratio is 1:1.

[0030] (2) Take the tin-nickel cyanide rubber system obtained in step (1) as a precursor, add an equivalent amount of reducing agent hydrazine hydrate to it, let stand for 0.1 hour to fully react the tin-nickel cyanide rubber and the reducing agent, wash the product, and then The three-dimensional nanoporous tin-nickel alloy is obtained by drying under the protection of an inert gas. The result is similar to Example 1.

Embodiment 3

[0032] (1) At 25°C, mix 0.1 mol / liter aqueous solution of nickel potassium cyanide with 0.1 mol / liter aqueous solution of tin tetrachloride to form a tin-nickel cyanide rubber system, in which potassium nickel cyanide and tin tetrachloride The molar ratio is 0.1:1.

[0033] (2) take the tin-nickel cyanide rubber system obtained in step (1) as a precursor, add excessive reducing agent sodium hypophosphite therein, leave standstill for 5 hours to make the tin-nickel cyanide rubber and reducing agent fully react, the product is washed, Subsequent drying under vacuum yielded a three-dimensional nanoporous tin-nickel alloy. The result is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com