Preparation method of three-dimensional nano porous tin-base alloy for lithium-ion battery negative electrode

A lithium-ion battery, three-dimensional nano technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems that limit the commercial application of tin-based alloys, and achieve the effect of simple preparation method and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) At 25°C, mix and react 0.6 mol / liter aqueous solution of nickel potassium cyanide and 0.6 mol / liter aqueous solution of tin tetrachloride to form a tin-nickel cyanide rubber system, in which potassium nickel cyanide and tin tetrachloride The molar ratio is 0.5:1.

[0025] (2) Take the tin-nickel cyanide rubber system obtained in step (1) as a precursor, add excessive reducing agent sodium borohydride therein, leave it to stand for 1 hour to fully react the tin-nickel cyanide rubber and the reducing agent, wash the product, and then Dry under vacuum to obtain a three-dimensional nanoporous tin-nickel alloy.

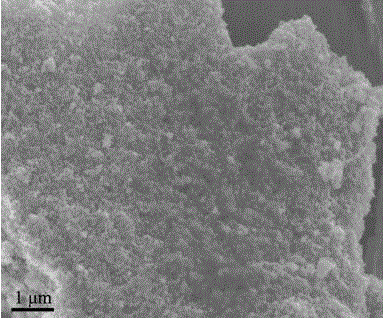

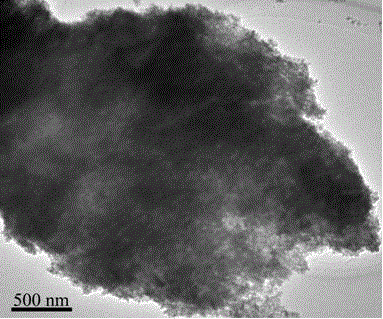

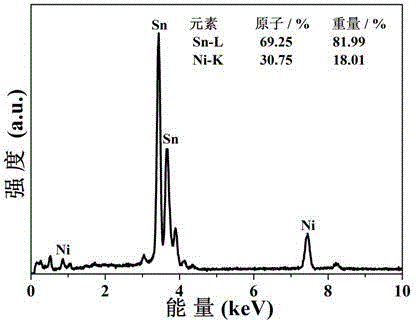

[0026] figure 1 , figure 2 , image 3 with Figure 4 They are the scanning electron micrographs, transmission electron micrographs, energy spectra and electrochemical performance diagrams of the three-dimensional nanoporous tin-nickel alloy synthesized in this example, respectively.

[0027] image 3 is the energy spectrum of the three-dimensional nanopor...

Embodiment 2

[0029] (1) At 0°C, mix and react 1 mol / liter aqueous solution of nickel potassium cyanide and 1 mol / liter aqueous solution of tin tetrachloride to form a tin-nickel cyanide rubber system, in which nickel potassium cyanide and tin tetrachloride The molar ratio is 1:1.

[0030] (2) Take the tin-nickel cyanide rubber system obtained in step (1) as a precursor, add an equivalent amount of reducing agent hydrazine hydrate to it, let stand for 0.1 hour to fully react the tin-nickel cyanide rubber and the reducing agent, wash the product, and then The three-dimensional nanoporous tin-nickel alloy is obtained by drying under the protection of an inert gas. The result is similar to Example 1.

Embodiment 3

[0032] (1) At 25°C, mix 0.1 mol / liter aqueous solution of nickel potassium cyanide with 0.1 mol / liter aqueous solution of tin tetrachloride to form a tin-nickel cyanide rubber system, in which potassium nickel cyanide and tin tetrachloride The molar ratio is 0.1:1.

[0033] (2) take the tin-nickel cyanide rubber system obtained in step (1) as a precursor, add excessive reducing agent sodium hypophosphite therein, leave standstill for 5 hours to make the tin-nickel cyanide rubber and reducing agent fully react, the product is washed, Subsequent drying under vacuum yielded a three-dimensional nanoporous tin-nickel alloy. The result is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com