Target material, preparation method thereof, and display device

A display device and target technology, which is applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of incompetent high-resolution active display devices, etc. The effect of high carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiments of the present invention provide a target material and a preparation method thereof. Specifically, the target material provided by the embodiment of the present invention has the atomic ratio shown in formula (I):

[0072] A a B b Ge c ZnO d (I),

[0073] Wherein, A and B are respectively any element in the elements Pb, Tl, Sn, Sb and Bi; the value ranges of a and b are both 0-100, including endpoint values, and a and b are not 0 at the same time, The value range of c is 0.01-100, including the endpoint value.

[0074] It should be noted that since the overall valence of the compound shown in formula (I) is zero, and A, B, Ge and Zn in formula (I) are all metal elements, their valences are positive, and only the valence of oxygen is negative. , so the value of d cannot be zero, and it depends on the elements represented by A and B and the specific values of a, b and c. Preferably, the value ranges of a and b are both 1-5, including the endpoint val...

Embodiment 2

[0084] According to the preset mass ratio of 239:97:81, the particle size is in the range of 0.1μm-500μm, and the purity is greater than 99.99% of PbO 2 Powder, Ge 2 o 3 powder and ZnO powder into the ball mill; then, stir the powders added into the ball mill to obtain mixed powder, wherein the stirring time range is preferably 3h, and the stirring speed range is preferably 2000rpm; then, use phenolic resin type of binder, cold-pressed in the range of 100MPa-150MPa, and sintered at 1300°C-1700°C for 4 hours-9 hours in an aerobic atmosphere to form a target blank, and finally, the target The blank is machined, polished, and surface smoothed to obtain a chemical formula of PbGeZnO 4.5 Target materials in atomic ratios indicated.

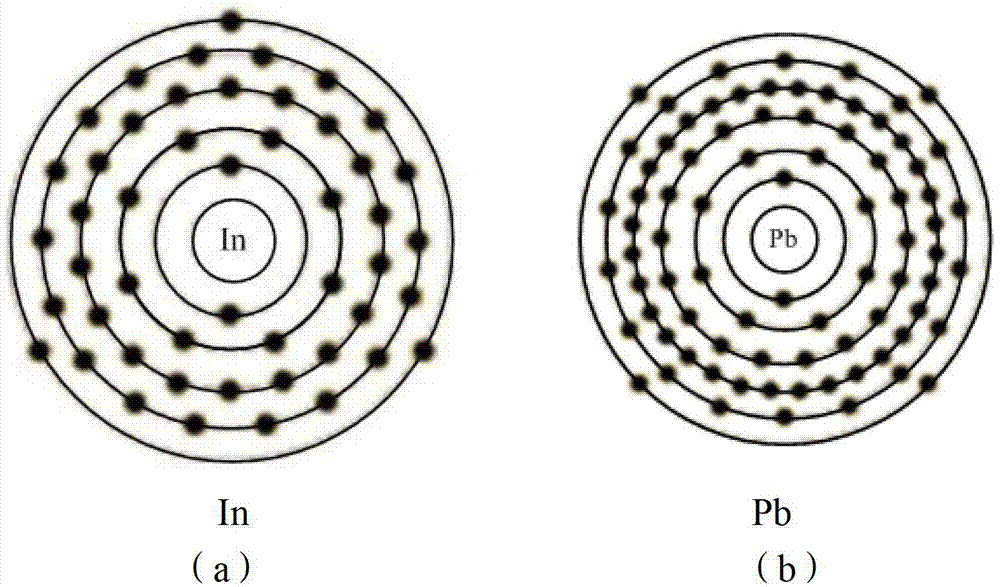

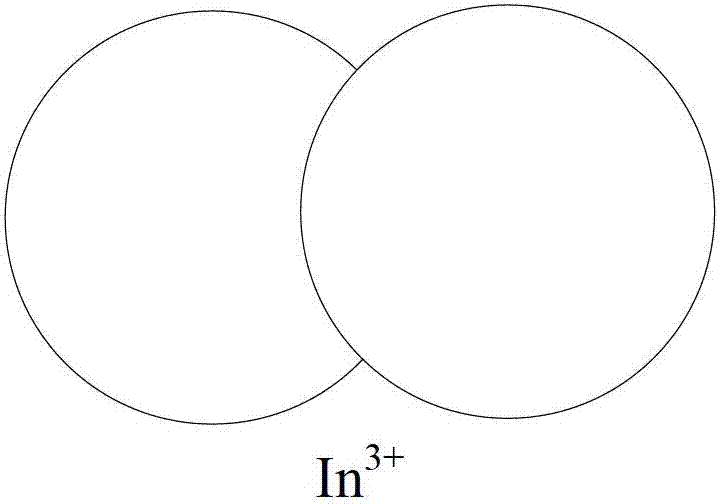

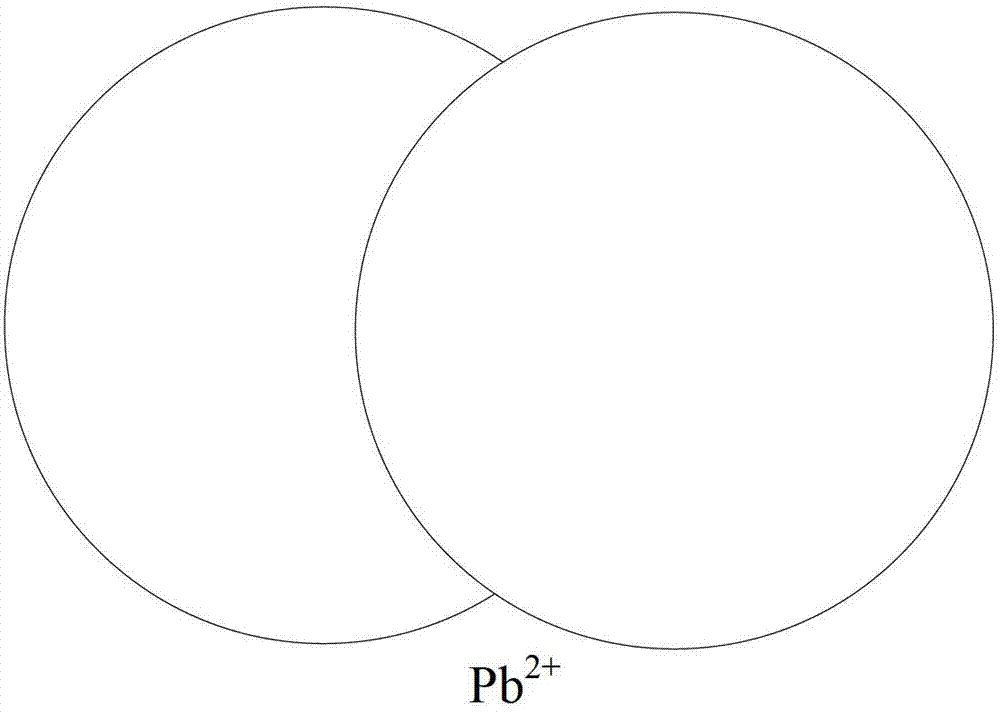

[0085] Such as figure 1 As shown, the electronic structure of Pb is 1s 2 2s 2 p 6 3s 2 p 6 d 10 4s 2 p 6 d 10 f 14 5s 2 p 6 d 10 6s 2 p 2 , the ionic radius is The electronic structure of In is 1s 2 2s 2 p 6 3s 2 p 6 d 10 4s ...

Embodiment 3

[0088] According to the preset mass ratio of 228:97:81, the particle size is in the range of 0.1μm-500μm, and the purity is greater than 99.99% of Tl 2 o 3 Powder, Ge 2 o 3 powder and ZnO powder into the ball mill; then, stir the powders added into the ball mill to obtain mixed powder, wherein the stirring time range is preferably 3h, and the stirring speed range is preferably 2000rpm; then, use phenolic resin type of binder, cold-pressed in the range of 100MPa-150MPa, and sintered at 1300°C-1700°C for 4 hours-9 hours in an aerobic atmosphere to form a target blank, and finally, the target The blank is machined, polished, and surface smoothed to obtain a chemical formula TlGeZnO 4 Target materials in atomic ratios indicated.

[0089] Such as Figure 4 As shown, the electronic structure of Tl is 1s 2 2s 2 p 6 3s 2 p 6 d 10 4s 2 p 6 d 10 f 14 5s 2 p 6 d 10 6s 2 p 1 , the ionic radius is The electronic structure of In is 1s 2 2s 2 p 6 3s 2 p 6 d 10 4s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com