Method for strengthening welding line by laser temperature shock free of absorption layer

A technology of impact strengthening and laser strengthening, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of poor corrosion resistance of welded parts, short high temperature fatigue life, insufficient depth and refinement of surface grains, etc., to improve Effect of Corrosion Resistance and High Temperature Fatigue Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

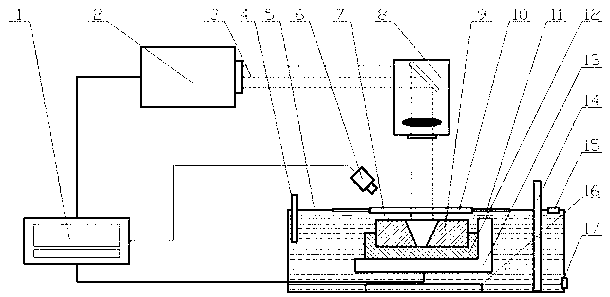

[0032] The specific steps of implementing a method of laser temperature shock strengthening weld seam without absorbing layer are as follows:

[0033](1) Clean and polish the welding seam of the weldment 9, the material of the weldment is Cu-32% (wt) Zn alloy, open the movable cover 11 above the vacuum box 5, and clamp the weldment 9 on the five On the tool holder 12 on the shaft table 13. There is no need to apply an absorbent layer to the weld, and the five-axis worktable 13 is moved into the vacuum box 5 through the computer control system 1, and the movable cover 11 above the vacuum box 5 is closed;

[0034] (2) Inject 710 type high temperature resistant silicone oil into the vacuum box, use the liquid level gauge 14 to monitor the thickness of the constrained layer 7 above the welded part 9, and control the constrained layer 7 above the welded part 9 through the liquid filling valve 15 and the liquid discharge valve 17 The thickness is 1-2 mm, the monitoring data is retu...

Embodiment 2

[0038] Change the pulse laser parameters in Example 1 to: pulse width 30 ns, repetition frequency 100 Hz, pulse energy 20 J, spot diameter 5 mm, Cu-32% (wt) Zn alloy heated to 126 ° C, other methods and The steps are unchanged.

Embodiment 3

[0040] Change the pulse laser parameters in Example 1 to: pulse width 10 ns, repetition rate 50 Hz, pulse energy 10 J, spot diameter 2.5 mm, Cu-32% (wt) Zn alloy heated to 80 ° C, other methods and The steps are unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com