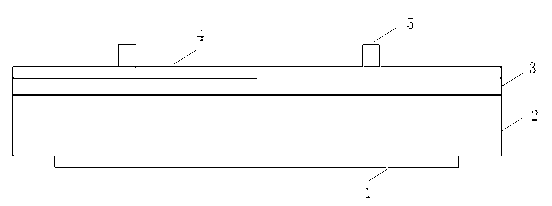

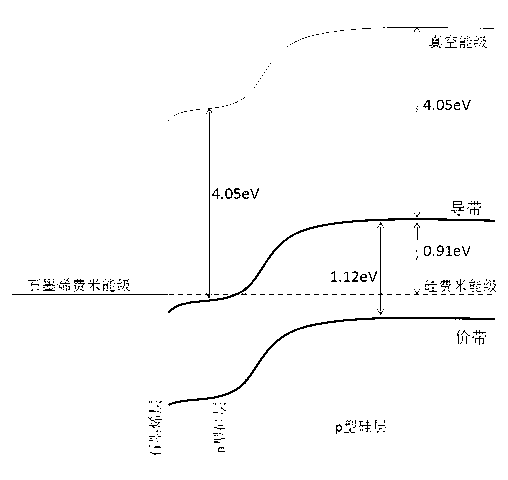

Graphene/silicon solar cell and manufacturing method thereof

A silicon solar cell and graphene technology, applied in the field of solar energy, to achieve the effect of reducing series resistance, increasing output power and increasing open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Immerse the p-type monocrystalline silicon wafer in a NaOH alkali solution with a mass concentration of 3% to form a textured structure on the surface of the p-type silicon layer;

[0024] 2) Put the textured sample into a diffusion furnace for phosphorus diffusion to form an n-type silicon layer. The diffusion temperature is 850°C and the surface doping concentration is 10 18 cm -3 , the junction depth is 0.2μm;

[0025] 3) Use laser etching to remove the edge doped layer;

[0026] 4) Transfer the n-type doped graphene to the phosphorus-doped n-type silicon layer, the graphene doping concentration is 10 12 cm -2 ;

[0027] 5) Print Ag and Al paste on the back of the p-type silicon layer and dry it, print Ag paste on the n-type doped graphene, and then put it into a belt sintering furnace for sintering, the sintering temperature is 950°C, and the time is 1min. The back electrode and the front electrode are fabricated to obtain a graphene / silicon solar cell.

Embodiment 2

[0029] 1) Immerse the p-type polysilicon wafer in HF / HNO 3 Etching in a mixed solution with a volume ratio of 3:1 to form a suede on the surface of the p-type silicon layer;

[0030] 2) Put the textured sample into a diffusion furnace for phosphorous diffusion to form an n-type silicon layer, the diffusion temperature is 900°C, and the surface doping concentration is 10 21 cm -3 , the junction depth is 0.4μm;

[0031] 3) Plasma etching is used to remove the edge doped layer;

[0032] 4) Transfer the n-type doped graphene to the phosphorus-doped n-type silicon layer, the graphene doping concentration is 2×10 13 cm -2 ;

[0033] 5) Print Ag and Al paste on the back of the p-type silicon layer and dry it, print Ag paste on the n-type doped graphene, and then put it into a belt sintering furnace for sintering, the sintering temperature is 850°C, and the time is 3min. The back electrode and the front electrode are fabricated to obtain a graphene / silicon solar cell.

Embodiment 3

[0035] 1) Immerse the p-type monocrystalline silicon wafer in a NaOH alkali solution with a mass concentration of 2%, so that the surface of the p-type silicon layer forms a textured structure;

[0036] 2) Phosphorus ion implantation was performed on the textured sample to form an n-type silicon layer with a surface doping concentration of 10 19 cm -3 , the junction depth is 0.6μm;

[0037] 3) Laser etching is used to remove the edge doped layer;

[0038] 4) Transfer the n-type doped graphene to the phosphorus-doped n-type silicon layer, the graphene doping concentration is 5×10 12 cm -2 ;

[0039] 5) Thermally evaporate the aluminum electrode on the back of the p-type silicon layer, thermally evaporate the gold electrode on the n-type doped graphene, and then put it into a belt sintering furnace for sintering. The sintering temperature is 400°C and the time is 30min. The back electrode and the front electrode After the fabrication is completed, a graphene / silicon solar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com