Intermediate compounds and process for the preparation of fingolimod

A technology of compounds and catalysts, applied in the field of intermediate compounds and methods for the preparation of fingolimod, capable of solving problems such as difficult operation and low total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

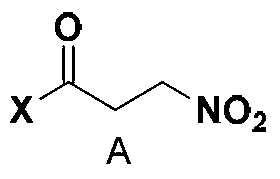

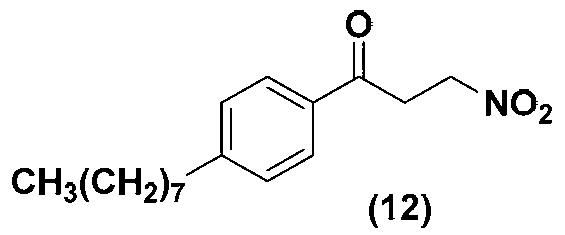

[0196] Example 1 : Preparation of 3-nitro-1-(4-octylphenyl)propan-1-one (12)

[0197] In a dry flask, 3-nitropropionic acid [commercially available or prepared according to Silva, P.C.; Costa, J.S.; Pereira, V.L.P. Synth. Commun. 2001, 31, 595, (10.0 g, 85.0 mmol)] was mixed with SOCl 2 (100ml) was stirred overnight. After addition of anhydrous toluene, the solution was azeotropically distilled to remove excess SOCl 2 . The residue can be used directly for acylation or distillation (80-83°C / 0.1-0.2mbar [SYNTHESIS 2009, No.5, p.715]) to provide pure 3-nitropropionyl chloride as a clear liquid.

[0198] AlCl 3 (12.0 g, 89.0 mmol) was added to 15 ml of methylene chloride and cooled to 0-5°C, followed by the addition of 3-nitropropionyl chloride (11 g, 80 mmol). Octylbenzene (17.10 g, 89.0 mmol) was added dropwise to 40 ml of CH 2 Cl 2 and the solution was stirred at room temperature under TLC monitoring. After the reaction was complete, the mixture was poured onto ice, a...

Embodiment 2

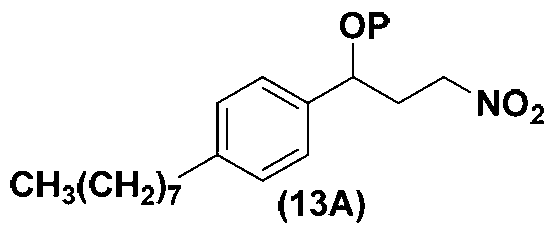

[0199] Example 2 : Preparation of 3-nitro-1-(4-octylphenyl)propyl acetate (13)

[0200] To a solution of 3-nitro-1-(4-octylphenyl)propan-1-one (12) (5.00 g) in methanol (25 ml) was added sodium borohydride (0.8 g) at 0°C , and the mixture was left to stand at room temperature for 4.5 hr. The suspension was diluted with ethyl acetate and washed successively with 1N HCl, sodium bicarbonate solution and brine. The ethyl acetate layer was passed through anhydrous Na 2 SO 4 Dried and concentrated. Pyridine (1.5eq), dichloromethane (10v) and acetic anhydride (10eq) were added to the residue, and the mixture was allowed to stand at room temperature overnight. Ice water was added to the reaction mixture, and the mixture was extracted with ethyl acetate and washed successively with 1N HCl, sodium bicarbonate solution and brine. The ethyl acetate solution was dried over sodium sulfate and concentrated. The residue is pure enough for the next transformation or can be purified by ...

Embodiment 3

[0201] Example 3 : Preparation of 2-nitro-2-[2-(4-octylphenyl)ethyl]propan-1,3-diol (14)

[0202] To a mixture of paraformaldehyde (0.13 mol, 9 eq) was added dropwise 4 ml (1.5 eq) of triethylamine in 40 ml of 1,4-dioxane at room temperature and with stirring, in 50 ml of 1, 3-nitro-1-(4-octylphenyl)propyl acetate (13) (5 g, 0.015 mol) in 4-dioxane, the mixture was slowly heated to 70 °C and controlled on TLC Stir at this temperature for 24 h. Water was added to the reaction mixture, and the pH of the mixture was adjusted to about 9-10, and stirred at 40° C. for 16 h for deprotection (monitored by TLC and HPLC). After the reaction was complete (about 2-3 h), the mixture was extracted with ethyl acetate and washed successively with 1N HCl, sodium bicarbonate solution and brine. The ethyl acetate solution was dried over sodium sulfate and concentrated. The residue is pure enough for the next transformation or can be purified by crystallization or silica gel column chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com