High-efficiency near-infrared light compound photocatalyst and preparation method thereof

A near-infrared light and composite light technology, applied in the field of photocatalytic materials, can solve the problems of reducing the redox potential of photogenerated electrons and holes, reducing the photocatalytic activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

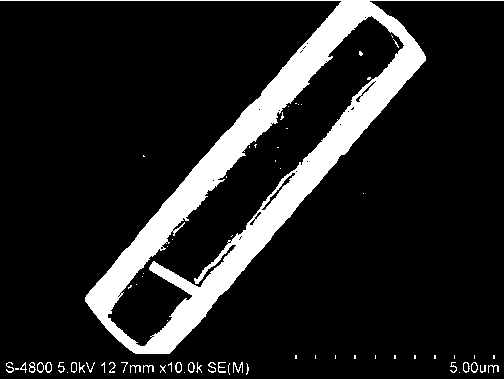

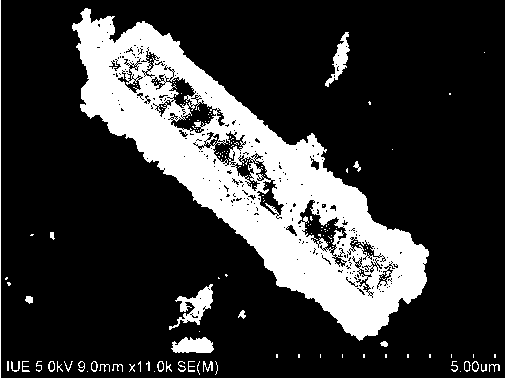

Image

Examples

Embodiment 1

[0019] Embodiment 1: Preparation of up-conversion luminescent material

[0020] Take 0.292g of EDTA in 10mL of ultrapure water and magnetically stir for 30min, then add a certain amount of LnCl dropwise 3 stock solution, i.e. YCl 3 (0.5M) 1.488mL, YbCl 3 (0.5M) 0.5mL, TmCl 3 (0.05M) 0.12mL, magnetically stirred for 60min, then 10mL of 16mmol NaF aqueous solution was added dropwise, magnetically stirred for 60min, the precursor was transferred to a 50mL sealed reaction kettle with a polytetrafluoroethylene liner, and placed to dry Hydrothermal reaction at 200 °C in the box for 18 hours, then naturally cooled to room temperature, and a 1:1 mixed solution of ultrapure water and absolute ethanol was passed through a desktop centrifuge for 10 hours. 4 Rpm / 10min centrifuge and wash the product 3 to 5 times, then put the precipitate in a vacuum drying oven at 80°C for 12 hours, and then put the product in a box-type atmosphere resistance furnace, in N 2 Calcined at 400°C for 90 m...

Embodiment 2

[0021] Embodiment 2: Preparation of near-infrared light composite photocatalyst

[0022] 50mg of up-conversion luminescent material and 50mg of TiO 2 (P-25) Add 50mL of absolute ethanol, ultrasonically disperse for 30min, then magnetically stir for 24h, use a 1:1 mixture of ultrapure water and absolute ethanol to pass through a desktop centrifuge for 10 4 The product was washed by centrifugation at rpm / 10min for 3 to 5 times, and then the precipitate was put into a vacuum drying oven at 80° C. for 12 hours, and ground to obtain a near-infrared photocomposite photocatalyst.

Embodiment 3

[0023] Example 3: Performance of near-infrared light composite photocatalyst for degradation of methyl orange (MO)

[0024] Weigh 5 mg of the near-infrared photocatalyst prepared above into 0.5 mL of 20 ppm MO, and let it stand in the dark for 12 h to reach adsorption equilibrium. Then, under the irradiation of 980nm near-infrared laser, the photodegradation experiment was carried out, and the absorbance of the solution after a certain period of degradation was measured by a spectrophotometer, and the absorbance-concentration standard curve table was checked, and the degradation rate of MO was calculated to be 53.8% after 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com