Fluoride-free mold powder for low-carbon steel

A technology for continuous casting of mold slag and low-carbon steel, applied in the metallurgical field, can solve the problems of increased equipment maintenance costs, poor application prospects, unfavorable lubrication, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

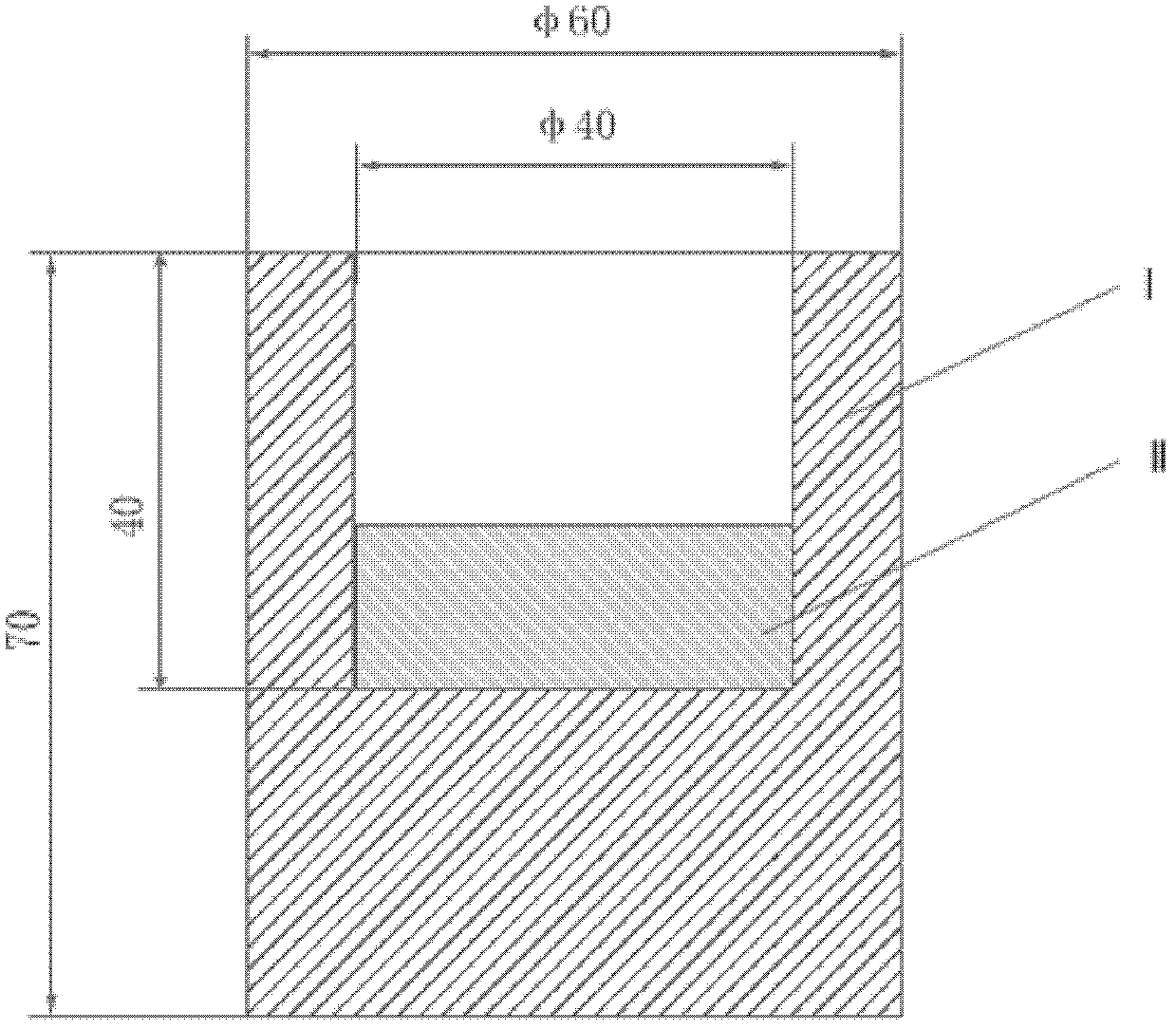

Image

Examples

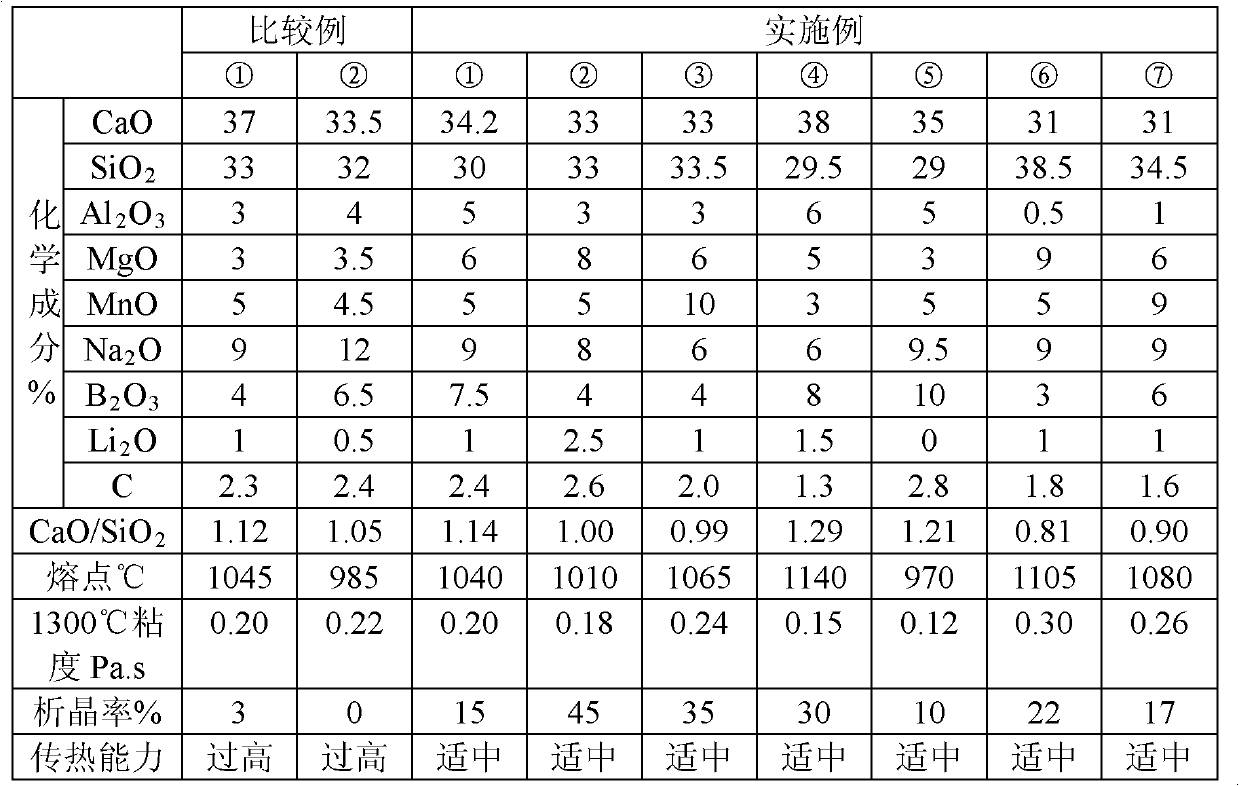

Embodiment 1-7

[0038] The following materials (but not limited to) are used to prepare mold flux: limestone, quartz, wollastonite, magnesia, bauxite, soda ash, borax, boronite, manganese carbonate, pigment manganese, lithium carbonate, lithium concentrate, etc.

[0039] Grind the above raw materials into fine powder, mix them uniformly according to the target ingredients, and then perform pre-melting treatment to form a complex solid solution between the various substances, and release volatiles such as carbonate and water at the same time to obtain faster and more uniform melting. The premelt material, after cooling and crushing, is ground again into a fine powder with a particle size of less than 0.075mm, fine-tuned with the above raw materials according to the composition deviation, and the proportion of the premelt material should not be less than 70%, and then add an appropriate amount of carbon as required Black, graphite and other carbonaceous materials are mechanically mixed, or the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com