Method for manufacturing prestressed centrifugal anti-corrosion concrete hollow square piles through pre-tensioning method

A technology of corrosion-resistant concrete and hollow square piles, which is applied in the direction of manufacturing tools, reinforced molding, ceramic molding machines, etc., can solve the problems of unsuitable use, insufficient research on corrosion resistance and durability of precast concrete and related technology development, and low durability and other issues to achieve the effect of improving safety, improving durability and corrosion resistance, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

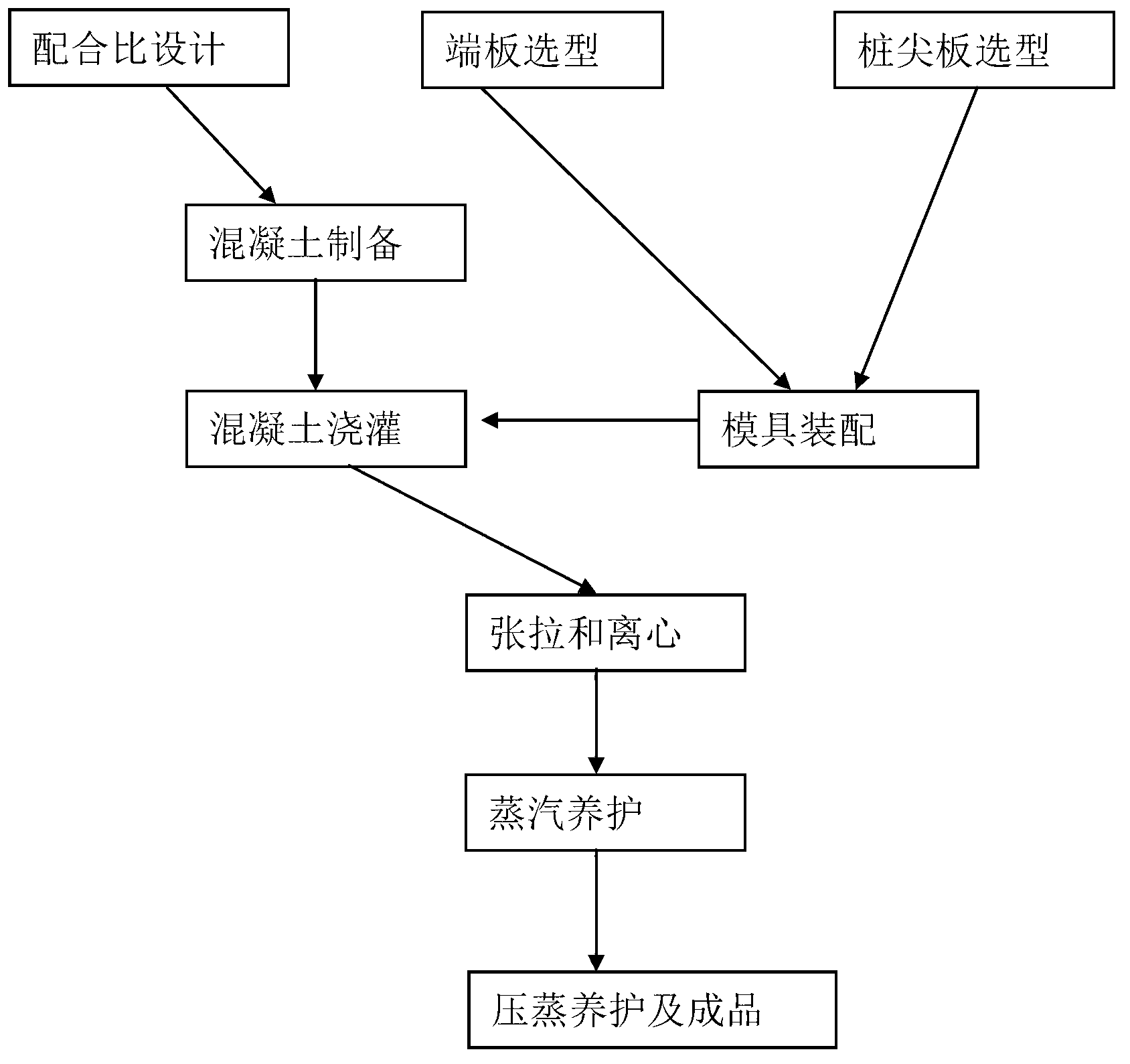

[0017] See figure 1 As shown, the specific production process of the pretensioned prestressed centrifugal corrosion-resistant concrete hollow square pile of this embodiment includes:

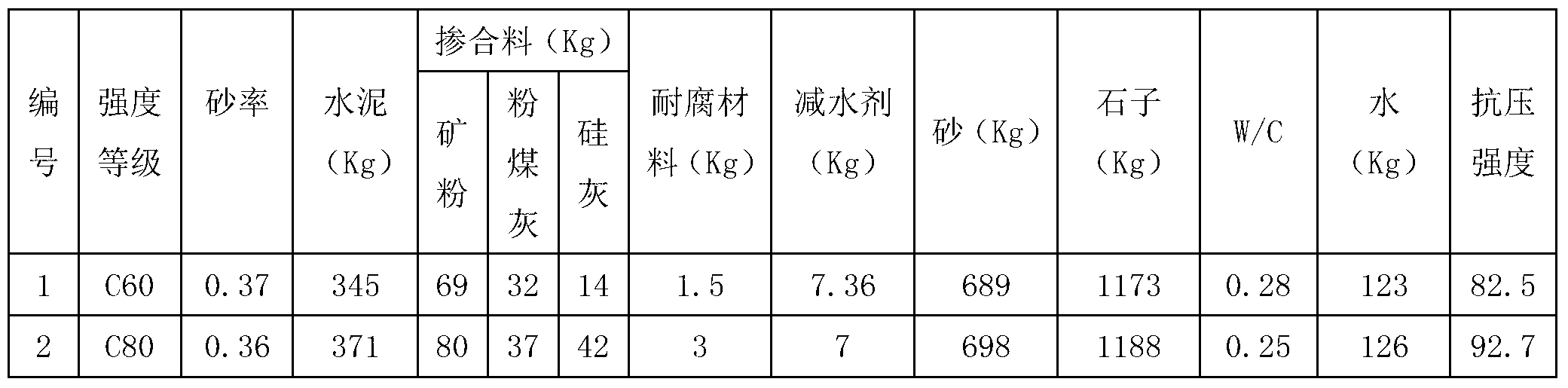

[0018] 1. Design the concrete mix ratio. Table 1 is the ratio of two kinds of concrete in this embodiment.

[0019] Table 1 Concrete mix ratio

[0020]

[0021] The above two proportions of concrete have higher corrosion resistance. In addition to traditional sand and gravel aggregates, cementitious materials, superplasticizer admixtures and water, its concrete components also add mineral admixtures and corrosion-resistant materials with excellent corrosion resistance. Mineral admixtures include fly ash, mineral powder and silica fume. Corrosion-resistant materials include barium hydroxide, sodium citrate, boric acid, sodium hexametaphosphate, sodium benzoate, sodium dodecylbenzenesulfonate, sodium dodecylsulfosulfate, silica sand, etc. Depending on the corrosion mechanism and environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com