Borate-based red fluorescent powder used for white light LED and preparation method thereof

A technology of red fluorescent powder and borate, which is applied in the direction of chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems that the luminous efficiency cannot meet the actual needs, the preparation process is complicated, the reaction conditions are harsh, and the experimental conditions are met. Easy to control, easy to obtain raw materials, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

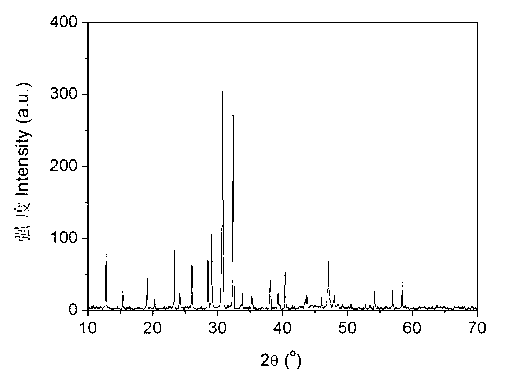

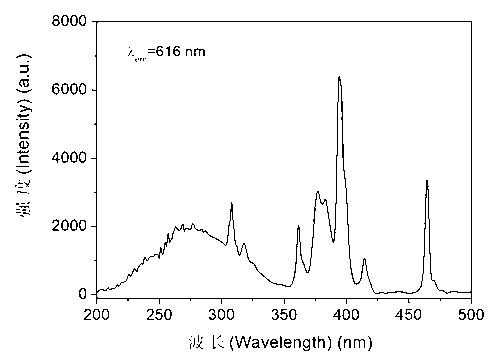

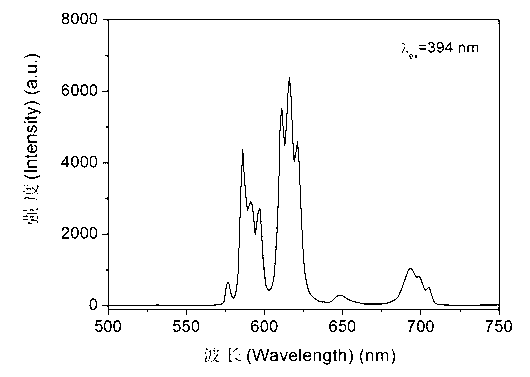

[0028] According to chemical formula La 1.4 CaB 8 o 16 :0.6Eu 3+ The molar ratio of each element in, weigh 22.8066 g of La 2 o 3 (0.0700mol), 10.0087 g of CaCO 3 (0.1000mol), 50.9504 g of H 3 BO 3 (0.8240mol) and 10.5578 g of Eu 2 o 3 (0.0300mol), the above raw materials are all analytically pure, mix the above raw materials evenly, put them into a corundum crucible, put them in a sintering furnace and raise the temperature to 450 °C at 50 °C / h, sintering time 24 h, cool to room temperature, take out and grind into The powder was put into a corundum crucible again and placed in a sintering furnace at a rate of 100 °C / h to 900 °C, the sintering time was 48 h, and the middle was taken out and ground for 3 times to obtain La 1.4 CaB 8 o 16 :0.6Eu 3+ red phosphor. The X-ray diffraction pattern of the phosphor is shown in figure 1 , excitation and emission spectra see figure 2 and image 3 . from figure 1 As you can see, La 1.4 CaB 8 o 16 :0.6Eu 3+ The phosph...

Embodiment 2

[0030] According to chemical formula La 1.6 CaB 8 o 16 :0.4Eu 3+ The molar ratio of each element in, weighed 26.0647 g of La 2 o 3 (0.0800mol), 12.8097 g of CaC 2 o 4 (0.1000mol), 51.9397 g of H 3 BO 3 (0.8400mol) and 7.0385 g of Eu 2 o 3 (0.0200mol), the above raw materials are all analytically pure, mix the above raw materials evenly, put them into a corundum crucible, put them in a sintering furnace and raise the temperature to 450 °C at 50 °C / h, sintering time 24 h, cool to room temperature, take out and grind into The powder was put into a corundum crucible again and placed in a sintering furnace at a rate of 100 °C / h to 850 °C, the sintering time was 48 h, and the middle was taken out and ground for 3 times to obtain La 1.6 CaB 8 o 16 :0.4Eu 3+ red phosphor. The X-ray diffraction pattern and fluorescence spectrum of the phosphor powder are similar to those of Example 1.

Embodiment 3

[0032] According to chemical formula La 1.6 CaB 8 o 16 :0.4Eu 3+ The molar ratio of each element in, weighed 26.0647 g of La 2 o 3 (0.0800mol), 16.4088 g of Ca(NO 3 ) 2 (0.1000mol), 29.2405 g of B 2 o 3 (0.4200mol) and 7.0385 g of Eu 2 o 3 (0.0200mol), the above raw materials are all analytically pure, mix the above raw materials evenly, put them into a corundum crucible, put them in a sintering furnace and raise the temperature to 450 °C at 50 °C / h, sintering time 24 h, cool to room temperature, take out and grind into The powder was put into a corundum crucible again and placed in a sintering furnace at a rate of 100 °C / h to 900 °C, the sintering time was 48 h, and the middle was taken out and ground for 3 times to obtain La 1.6 CaB 8 o 16 :0.4Eu 3+ red phosphor. The X-ray diffraction pattern and fluorescence spectrum of the phosphor powder are similar to those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com