Preparation method of castor-oil plant based biological aircraft fuel

An aviation fuel and castor-based technology, which is applied in the field of bio-aviation fuel preparation, can solve problems such as no bio-aviation fuel, and achieve the effects of stable source of raw materials, excellent performance at low temperature and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a fixed bed reactor, with Ni-Mo / Al 2 o 3 As a catalyst, the raw material castor oil is subjected to hydrodeoxygenation reaction. The reaction temperature is controlled at 340°C-360°C, the pressure is 2-4MPa, the LHSV is 1.0-1.5 / h, and the hydrogen-oil ratio is 600 Nm 3 / m 3 . After the reaction, the liquid product was collected in a sample bottle.

[0023] In a fixed-bed reactor, Pt / SAPO-11 was used as a catalyst to carry out hydroisomerization reaction on the hydrodeoxygenated liquid product, and the catalyst was reduced with hydrogen for 2 hours before use. The reaction temperature of the isomerization reaction is 384°C, the reaction pressure is 3MPa, the reaction volume space velocity is 3 / h, and the hydrogen-to-oil molar ratio is 12:1. After the reaction, the corresponding liquid product was collected.

[0024] The liquid product of hydroisomerization is fractionated, and the fraction between 200-300°C is taken as the final product.

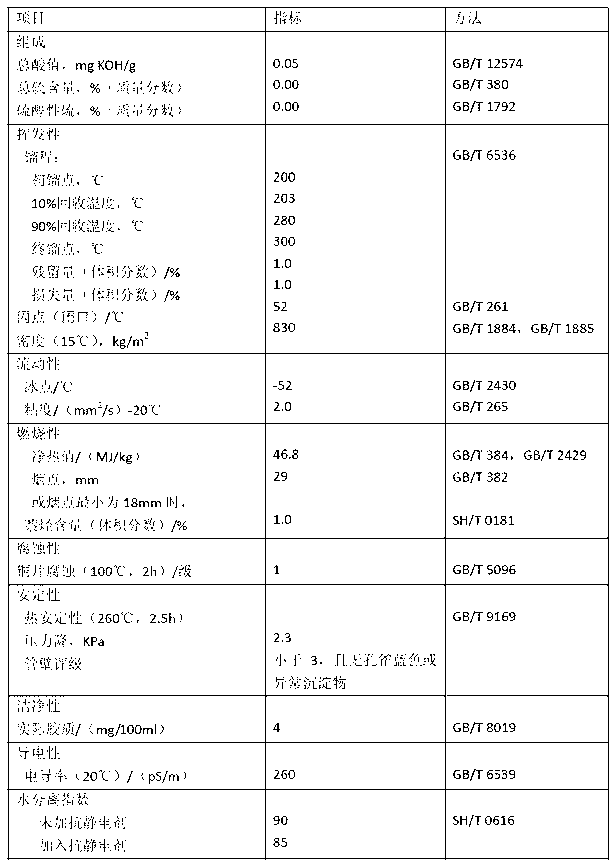

[0025]

Embodiment 2

[0027] In a fixed bed reactor, with Ni / Al 2 o 3 As a catalyst, the raw material castor oil is subjected to hydrodeoxygenation reaction. The reaction temperature is controlled at 334°C-362°C, the pressure is 2.3-4.0MPa, the LHSV is 0.9-1.6 / h, and the hydrogen-oil ratio is 850 Nm 3 / m 3 . After the reaction, the liquid product was collected in a sample bottle.

[0028] In a fixed-bed reactor, Pd / ZSM-5 was used as a catalyst to carry out hydroisomerization reaction on the hydrodeoxygenated liquid product, and the catalyst was reduced with hydrogen for 2 hours before use. The reaction temperature of the isomerization reaction is 335°C, the reaction pressure is 3.9MPa, the reaction volume space velocity is 2.2 / h, and the hydrogen-to-oil molar ratio is 11.7:1. After the reaction, the corresponding liquid product was collected.

[0029] The hydroisomerized liquid product is distilled, and the fraction between 200-300°C is taken as the final product.

[0030]

Embodiment 3

[0032] In a fixed bed reactor, with Ni-Mo / Al 2 o 3 -MgAl 2 o 4 As a catalyst, the raw material castor oil is subjected to hydrodeoxygenation reaction. The reaction temperature is controlled at 346°C-380°C, the pressure is 2.1-3.9MPa, the LHSV is 0.6-1.0 / h, and the hydrogen-oil ratio is 950 Nm 3 / m 3 . After the reaction, the liquid product was collected in a sample bottle.

[0033] In a fixed-bed reactor, Pt / SAPO-41 was used as a catalyst to carry out hydroisomerization reaction on the hydrodeoxygenated liquid product, and the catalyst was reduced with hydrogen for 2 hours before use. The reaction temperature of the isomerization reaction is 340°C, the reaction pressure is 3.7MPa, the reaction volume space velocity is 2.2 / h, and the molar ratio of hydrogen to oil is 14.0:1. After the reaction, the corresponding liquid product was collected.

[0034] The hydroisomerized liquid product is distilled, and the fraction between 200-300°C is taken as the final product.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com