Silver-gold porous nanorod array, preparation method and purpose of silver-gold porous nanorod array

A nanorod array and nanorod technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of electromagnetic field enhancement of porous gold nanorods, failure to synthesize products, thin gold film thickness, etc. problem, to achieve the effect of improving the overall SERS activity, improving the electromagnetic field enhancement, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The concrete steps of preparation are:

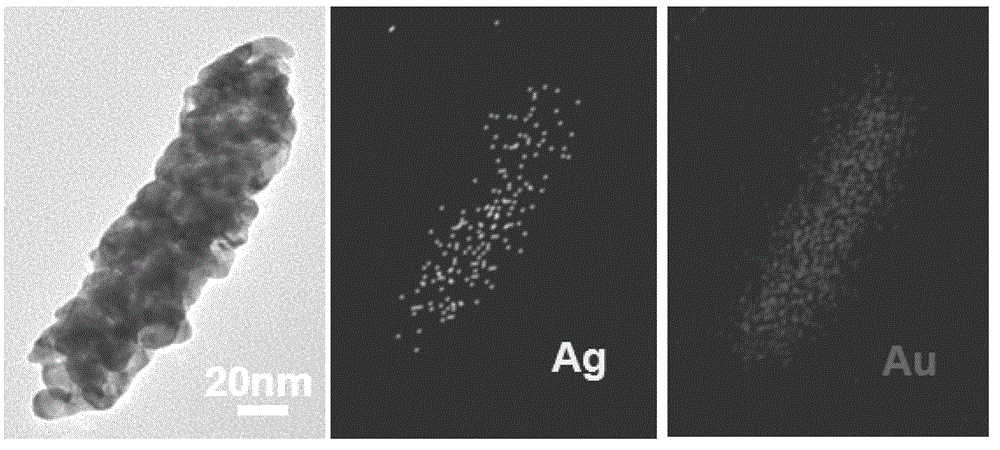

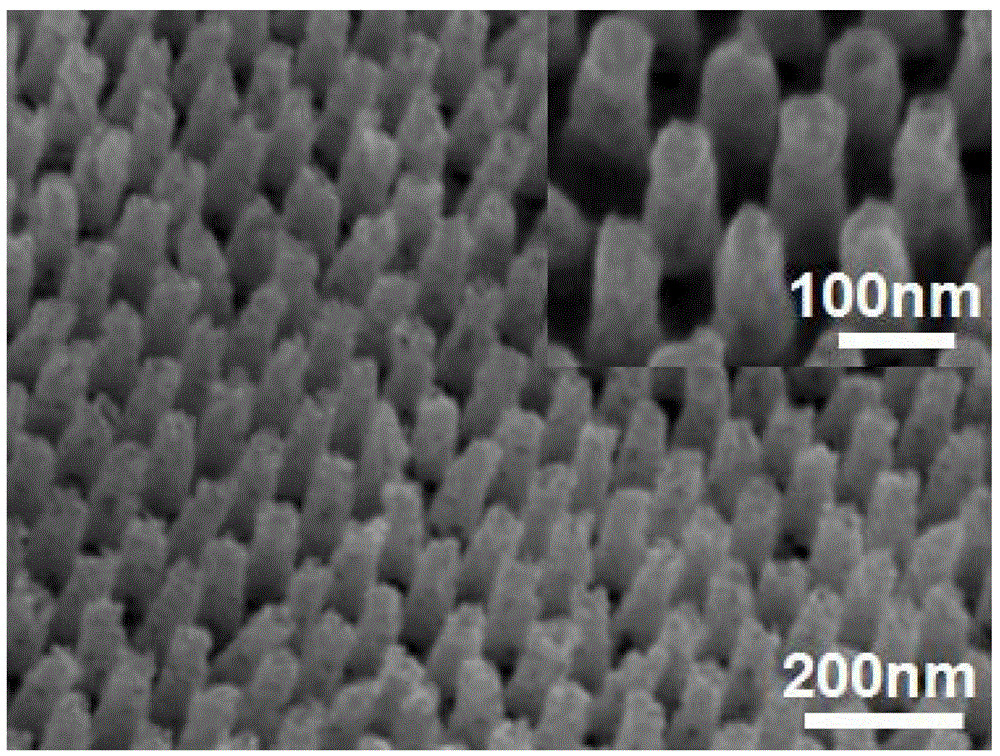

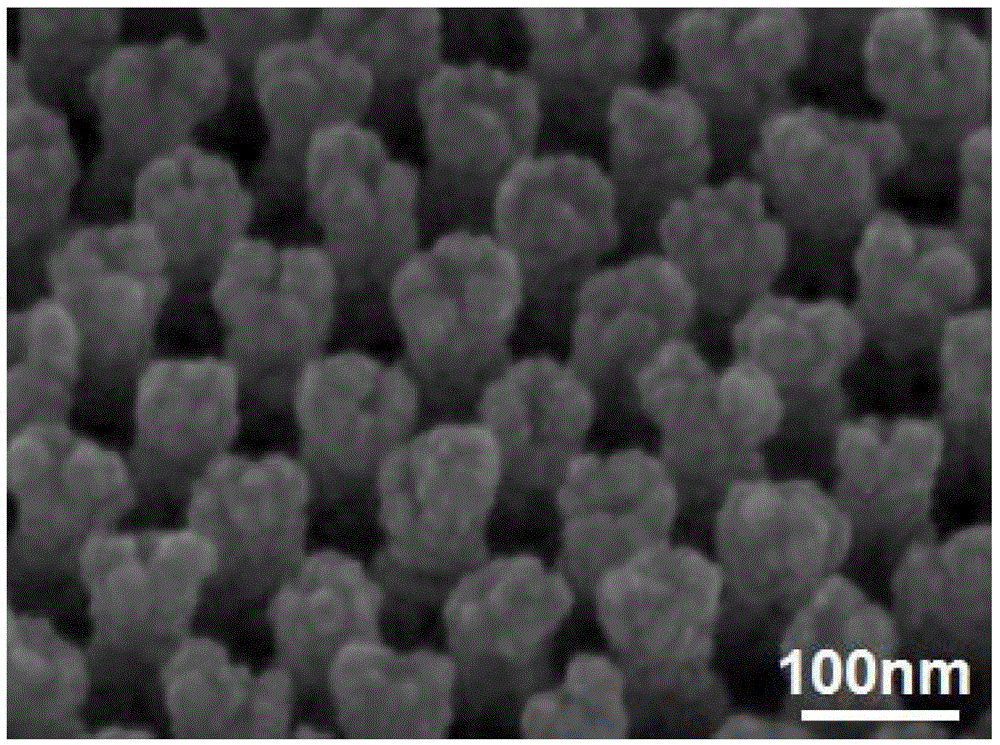

[0037] Step 1, first place the aluminum oxide template coated with a gold film on one side in the mixed electrolyte, and electrodeposit it under a constant voltage direct current voltage of 0.2V for 10 minutes; wherein, the mixed electrolyte is electrolyzed by silver nitrate electrolyte and chloroauric acid The solution is mixed according to the ratio of gold ions and silver ions contained in the two at a ratio of 1:2 to obtain an alumina template with a gold film on one side and an array of gold-silver alloy nanorods deposited in the holes. Then put the aluminum oxide template with a gold film on one side and gold-silver alloy nanorod arrays deposited in the holes in a nitric acid solution with a concentration of 65wt% at 0°C for 10 minutes to obtain a gold film on one side and gold-silver alloy nanorod arrays in the holes. Alumina templates for gold porous nanorod arrays.

[0038] Step 2, first coating liquid methyl methacryla...

Embodiment 2

[0041] The concrete steps of preparation are:

[0042] Step 1, first place the aluminum oxide template coated with a gold film on one side in the mixed electrolyte, and electrodeposit it under a constant voltage direct current voltage of 0.35V for 7 minutes; wherein, the mixed electrolyte is electrolyzed by silver nitrate electrolyte and chloroauric acid The solution is mixed according to the ratio of gold ions and silver ions contained in the two at a ratio of 1:3 to obtain an alumina template with a gold film on one side and an array of gold-silver alloy nanorods deposited in the holes. Then put the aluminum oxide template with a gold film on one side and gold-silver alloy nanorod arrays deposited in the holes in a nitric acid solution with a concentration of 66wt% at 0.5°C for 7.5 minutes to obtain a gold film on one side and a gold-silver alloy nanorod array in the holes. Alumina template with gold porous nanorod arrays.

[0043] Step 2, first coating liquid methyl methac...

Embodiment 3

[0046] The concrete steps of preparation are:

[0047]Step 1, first place the aluminum oxide template coated with a gold film on one side in the mixed electrolyte, and electrodeposit it under a constant voltage direct current voltage of 0.5V for 5 minutes; wherein, the mixed electrolyte is electrolyzed by silver nitrate electrolyte and chloroauric acid The solution is mixed according to the ratio of gold ions and silver ions contained in the two at a ratio of 1:3.5 to obtain an alumina template with a gold film on one side and gold-silver alloy nanorod arrays deposited in the holes. Then put the aluminum oxide template with a gold film on one side and gold-silver alloy nanorod arrays deposited in the holes in a nitric acid solution with a concentration of 67wt% at 1°C for 5 minutes to obtain a gold film on one side and gold-silver alloy nanorod arrays in the holes. Alumina templates for gold porous nanorod arrays.

[0048] Step 2, first coating liquid methyl methacrylate on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com