Environment-friendly sulfur-free foaming material as well as preparation method and application of environment-friendly sulfur-free foaming material

A foaming material, an environmentally friendly technology, applied in the field of environmentally friendly sulfur-free foaming materials and its preparation, can solve the problems of poor high temperature resistance and other problems, and achieve the effects of small compression set, excellent heat resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

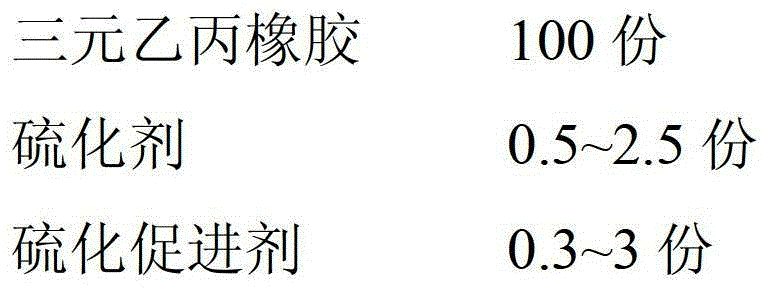

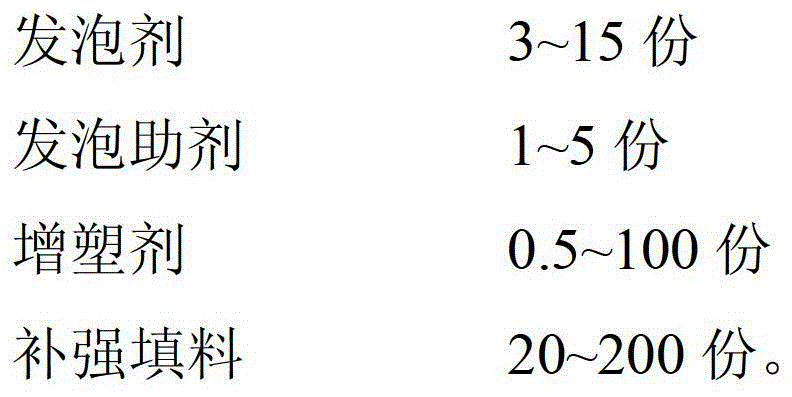

[0046] Embodiment 1: Preparation of an environmentally friendly sulfur-free foaming material

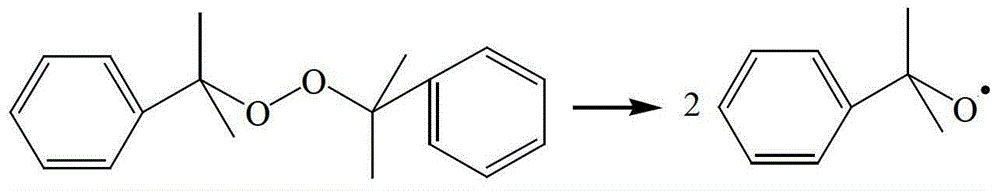

[0047] Put EPDM rubber, carbon black, light calcium carbonate, paraffin oil, stearic acid, etc. into the internal mixer, mix and masticate at 80°C for 20 minutes, and then discharge; after cooling, put it into the open mixer, Add vulcanizing agent, vulcanization accelerator, foaming agent and foaming aid at 80°C, pass through 10-15 times after the foaming agent is completely dispersed, and then release the sheet; put the material into the mold, Vulcanize for 30 minutes under the same conditions, and an environmentally friendly sulfur-free foam material can be obtained.

[0048] Wherein, 100 parts by weight of EPDM rubber, 1.5 parts by weight of vulcanizing agent DCP; 1.5 parts by weight of vulcanization accelerator TAIC; 9.5 parts by weight of foaming agent AC; 5 parts by weight of zinc oxide, a foaming aid; 30 parts by weight of carbon black 80 parts by weight of light calcium carb...

Embodiment 2

[0049] Embodiment 2: Preparation of an environmentally friendly sulfur-free foaming material

[0050] Put EPDM rubber, carbon black, light calcium carbonate, stearic acid, paraffin oil, etc. into the internal mixer, mix and masticate at 90°C for 20 minutes, and then discharge; after cooling, put it into the open mixer, Add vulcanizing agent, vulcanization accelerator, foaming agent and foaming aid at 100°C, pass through 10 to 15 times after the foaming agent is completely dispersed, and release the tablet; pre-vulcanize at 145°C for 15 minutes, Vulcanize for 10 minutes at 170°C to obtain an environmentally friendly sulfur-free foaming material.

[0051] Wherein, 100 parts by weight of EPDM rubber, 2.5 parts by weight of vulcanizing agent DCP; 0.3 parts by weight of vulcanization accelerator TAIC; 15 parts by weight of foaming agent AC; 3 parts by weight of zinc oxide, a foaming aid; 20 parts by weight of carbon black 50 parts by weight of light calcium carbonate; 0.5 parts by...

Embodiment 3

[0052] Example 3: Preparation of an environmentally friendly sulfur-free foaming material

[0053] Put EPDM rubber, carbon black, light calcium carbonate, paraffin oil, stearic acid, etc. into the internal mixer, mix and masticate at 110°C for 5 minutes, and then discharge; after cooling, put it into the open mixer, Add vulcanizing agent, vulcanization accelerator, foaming agent and foaming aid under the condition of 100°C. After the foaming agent is completely dispersed, pass through it 10-15 times, and the sheet is produced; put the material into a 20mm thick mold, Vulcanize for 120 minutes under the condition of ℃, and an environmentally friendly sulfur-free foam material can be obtained.

[0054] Among them, 100 parts by weight of EPDM rubber, 0.5 parts by weight of vulcanizing agent DCP; 3 parts by weight of vulcanization accelerator TAIC; 3 parts by weight of foaming agent 4,4'-bis-sulfonyl hydrazide diphenyl ether; foaming aid 2 parts by weight of zinc oxide; 10 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com