A kind of manufacture method of surface modification matting agent for nylon chemical fiber

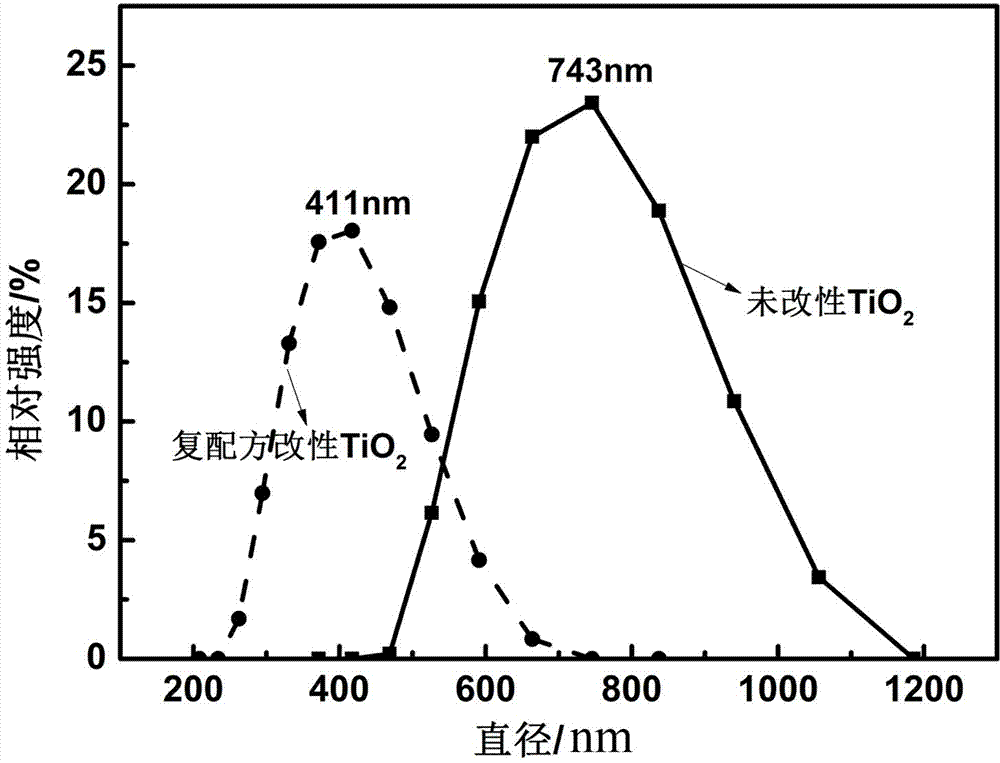

A surface modification and matting agent technology, applied in chemical instruments and methods, fibrous fillers, dyed organosilicon compound treatment, etc. Chain length and other issues, to achieve the effect of increasing steric hindrance, improving dispersibility, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Coating oxide film by precipitation method

[0043] Weigh 10g TiO at room temperature 2 The powder was dispersed in 60ml of absolute ethanol, after stirring for 60min, 0.1g of butyl titanate was added, and magnetically stirred at room temperature for 30min. Slowly add a solution of 2ml deionized water and 30ml absolute ethanol dropwise to the obtained dispersion, continue stirring for 30min, then ultrasonically disperse for 30min, and age at room temperature for 24h to obtain TiO 2 Dispersions.

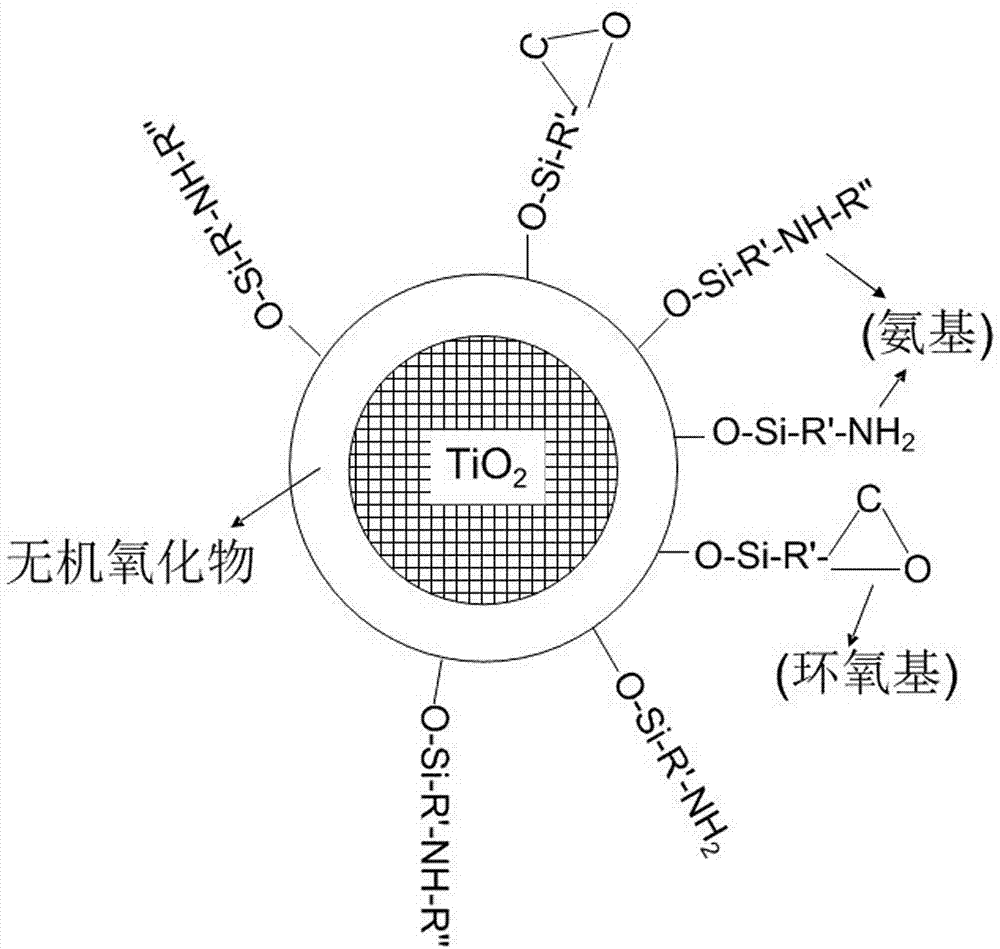

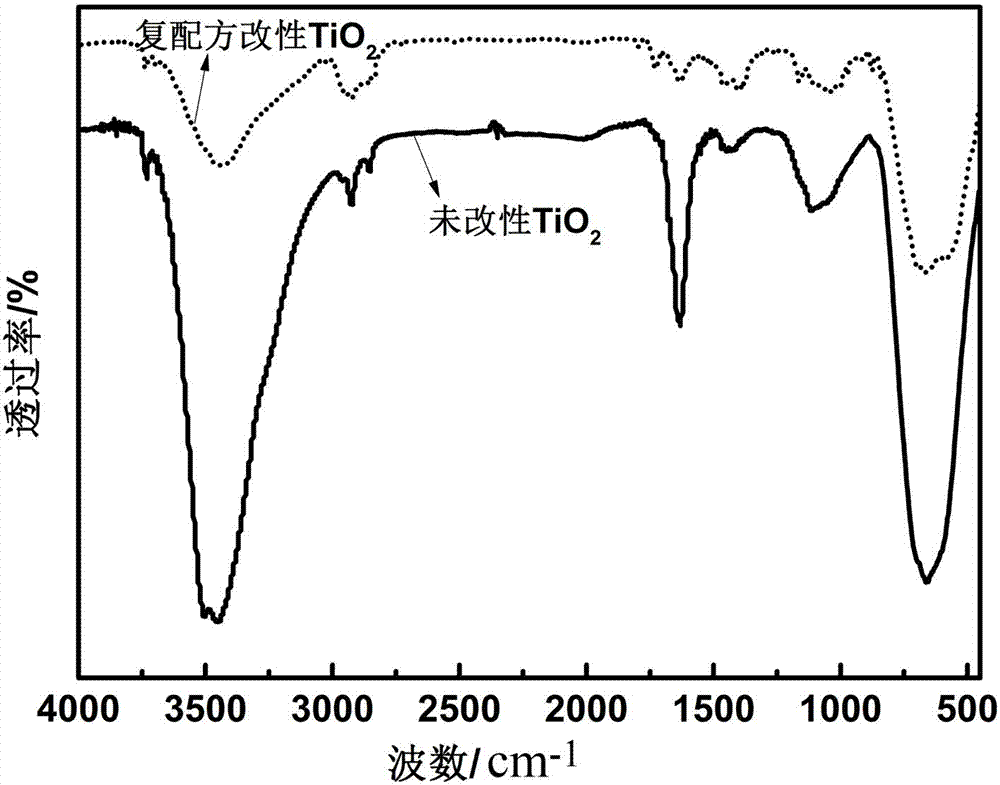

[0044] (2) Surface modification by compound coupling agent method

[0045] TiO obtained in step (1) 2 Add 30ml of absolute ethanol to the dispersion, stir magnetically for 30min to disperse the aged liquid evenly, then add 0.1g of compound coupling agent, wherein the molar ratio of the amino group-containing coupling agent to the epoxy group-containing coupling agent is 1:1, the coupling agent containing amino groups is N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane (KH...

Embodiment 2

[0049] (1) Coating oxide film by precipitation method

[0050] Weigh 10g TiO at room temperature 2 The powder was dispersed in 60ml of absolute ethanol, after stirring for 60min, 1g of ethyl orthosilicate was added, and magnetically stirred at room temperature for 60min. Slowly add a solution of 2ml deionized water and 30ml absolute ethanol dropwise to the obtained dispersion, continue stirring for 60min, then ultrasonically disperse for 60min, and age for 32h at room temperature to obtain TiO 2 Dispersions.

[0051] (2) Surface modification by compound coupling agent method

[0052] TiO obtained in step (1) 2 Add 30ml of absolute ethanol to the dispersion, stir magnetically for 60 minutes to disperse the aged liquid evenly, then add 2g of compound coupling agent, wherein the compound molar ratio of the amino group-containing coupling agent to the epoxy group-containing coupling agent is 4:1, the amino group-containing coupling agent is bis(triethanolamine) diisopropyl tit...

Embodiment 3

[0057] (1) Coating oxide film by precipitation method

[0058] Weigh 10g TiO at room temperature 2 The powder was dispersed in 60ml of absolute ethanol, after stirring for 60min, 1g of butyl titanate and 1g of ethyl orthosilicate were added, and magnetically stirred at room temperature for 120min. Slowly add a solution of 2ml deionized water and 30ml absolute ethanol dropwise to the obtained dispersion, continue stirring for 120min, then ultrasonically disperse for 120min, and age at room temperature for 48h to obtain TiO 2 Dispersions.

[0059] (2) Surface modification by compound coupling agent method

[0060] TiO obtained in step (1) 2 Add 30ml of absolute ethanol to the dispersion, stir it magnetically for 60 minutes to disperse the aged liquid evenly, then add 1g of compound coupling agent, wherein the compound molar ratio of the amino group-containing coupling agent to the epoxy group-containing coupling agent is 2:1, the coupling agent containing amino group is γ-am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com