Preparation method of autodoped modified high-conductivity TiO2 nanotube array

A nanotube array and electrode technology, which is applied in the field of nanomaterials, can solve problems such as inequalities, and achieve the effects of simple process, superior energy storage performance, and saving raw materials and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Substrate pretreatment: polish the pure titanium sheet until there is no scratch on the surface, then ultrasonically clean it in acetone, ethanol, and deionized water, and dry it;

[0031] 2) Preparation of electrolyte: weigh a certain amount of NH 4 F was dissolved in a mixture of deionized water and glycerol with a volume ratio of 1:9 to prepare a 1mol / L electrolyte;

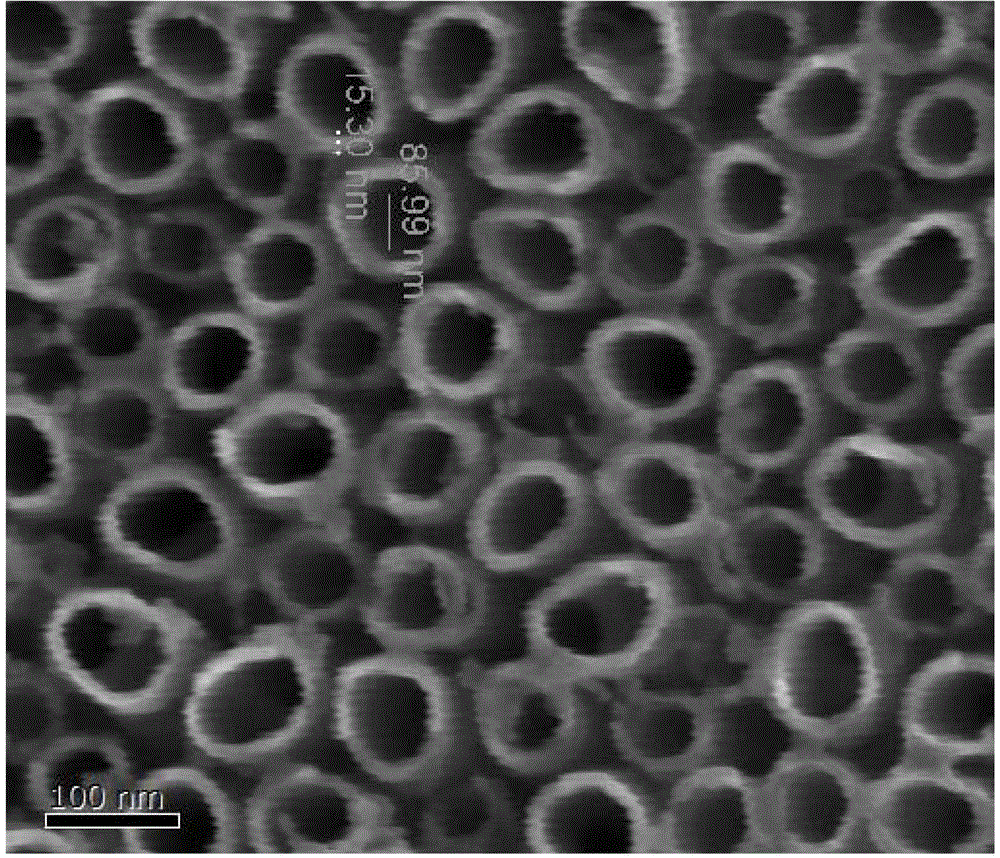

[0032] 3) Preparation of TiO by anodic oxidation 2 Nanotubes: With the treated titanium sheet as the anode and the platinum sheet as the cathode, the anodic oxidation reaction was carried out at 20V DC voltage for 3 hours. After the reaction, it was washed with deionized water and dried in air to obtain amorphous TiO 2 nanotube arrays;

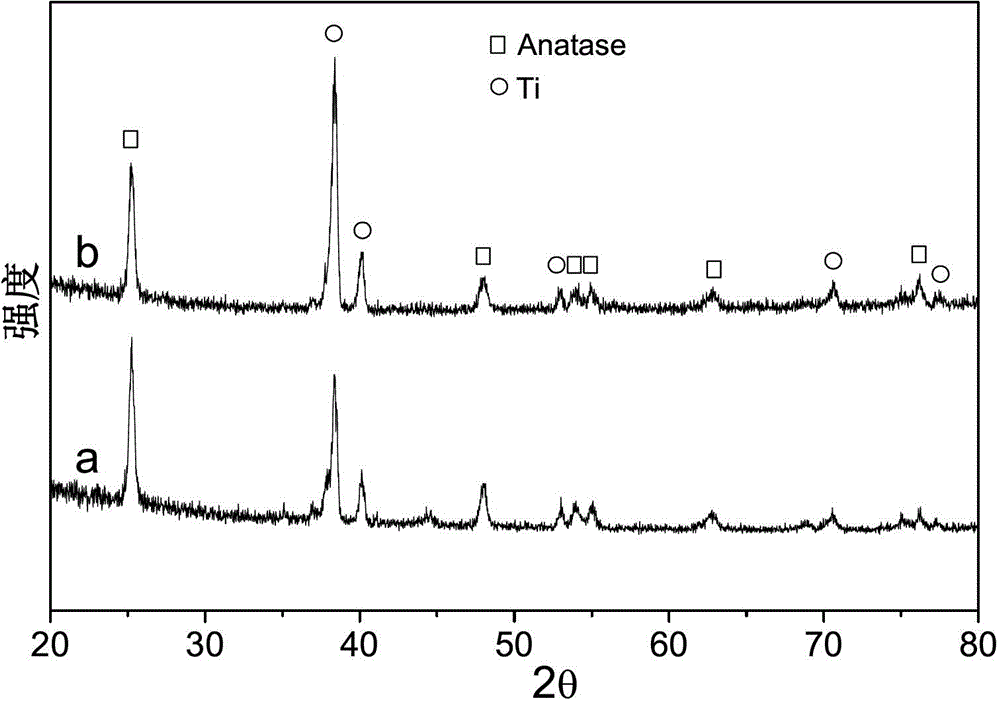

[0033] 3) The amorphous TiO 2 The nanotubes were placed in a muffle furnace, calcined at 450 °C for 2 h, and cooled naturally to obtain anatase crystal TiO 2 Nanotube array, its XRD spectrum is as follows figure 1 shown;

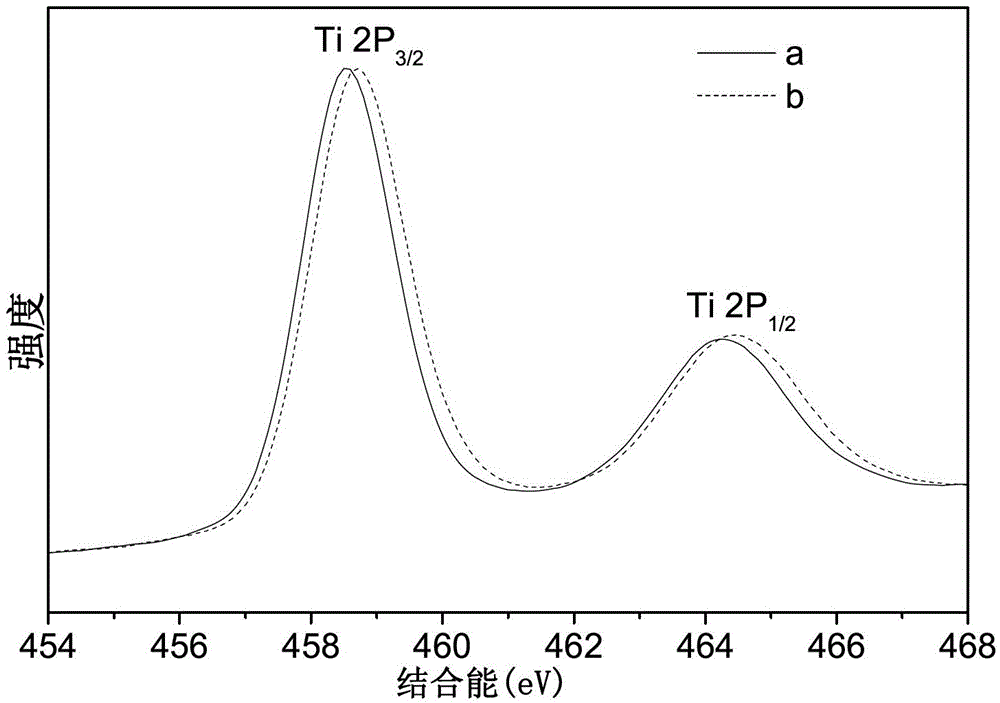

[0034] 4) Preparation of self-doped Ti...

Embodiment 2

[0036] 1) Substrate pretreatment: polish the pure titanium sheet until there is no scratch on the surface, then ultrasonically clean it in acetone, ethanol, and deionized water, and dry it;

[0037] 2) Preparation of electrolyte: Weigh a certain amount of NaF and dissolve it in a mixture of deionized water and ethylene glycol with a volume ratio of 1:100 to prepare a 0.1mol / L electrolyte;

[0038] 3) Preparation of TiO by anodic oxidation 2 Nanotubes: With the treated titanium sheet as the anode and graphite as the cathode, the anodic oxidation reaction was carried out at 10V DC voltage for 24 hours. After the reaction, it was washed with deionized water and dried in air to obtain amorphous TiO 2 nanotube arrays;

[0039] 3) The amorphous TiO 2 The nanotubes were placed in a muffle furnace, calcined at 700 °C for 1 h, and cooled naturally to obtain anatase crystal TiO 2 nanotube array,

[0040] 4) Preparation of self-doped TiO by cathodic reduction treatment 2 Nanotube ar...

Embodiment 3

[0042] 1) Substrate pretreatment: polish the pure titanium sheet until there is no scratch on the surface, then ultrasonically clean it in acetone, ethanol, and deionized water, and dry it;

[0043] 2) Preparation of electrolyte: weigh a certain amount of NH 4 F is dissolved in a mixture of deionized water and glycerin with a volume ratio of 5:1 to prepare a 1.5mol / L electrolyte;

[0044] 3) Preparation of TiO by anodic oxidation 2 Nanotubes: With the treated titanium sheet as the anode and glassy carbon as the cathode, the anodic oxidation reaction was carried out at a 70V DC voltage for 10 minutes. After the reaction was completed, it was washed with deionized water and dried in air to obtain amorphous TiO 2 nanotube arrays;

[0045] 3) The amorphous TiO 2 The nanotubes were placed in a muffle furnace, calcined at 400 °C for 16 hours, and cooled naturally to obtain anatase crystal TiO 2 nanotube arrays;

[0046] 4) Preparation of self-doped TiO by cathodic reduction tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com