Complex germicidal and algicidal agent

A technology of bactericidal algaecide and mixed solution, applied in the direction of herbicide, algicide, biocide, biocide, etc., can solve the secondary pollution of the circulating cooling water system, cannot be killed by ultraviolet rays, and the cooling pipe cannot be restored and other issues to achieve low cost, reduced usage, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 2g sulfamic acid is dissolved in 10g deionized water earlier in the compound bactericidal algicide process of preparing the present invention, then in sulfamic acid solution, add 40g dodecyl dimethyl benzyl ammonium chloride, through conventional stirring Make it mix evenly to form a mixed solution, then add 30g of glutaraldehyde into the mixed solution, and make it mix evenly through conventional stirring.

Embodiment 2

[0030] 4g sulfamic acid is dissolved in 13g deionized water earlier in the compound bactericidal algicide process of preparing the present invention, then in sulfamic acid solution, add 50g dodecyl dimethyl benzyl ammonium chloride, through conventional stirring Make it mix evenly to form a mixed solution, then add 40g of glutaraldehyde into the mixed solution, and make it mix evenly through conventional stirring.

Embodiment 3

[0032] 5g sulfamic acid is dissolved in 15g deionized water earlier in the compound bactericidal algicide process of preparing the present invention, then in sulfamic acid solution, add 60g dodecyl dimethyl benzyl ammonium chloride, through conventional stirring Make it mix evenly to form a mixed solution, then add 50g of glutaraldehyde into the mixed solution, and make it mix evenly through conventional stirring.

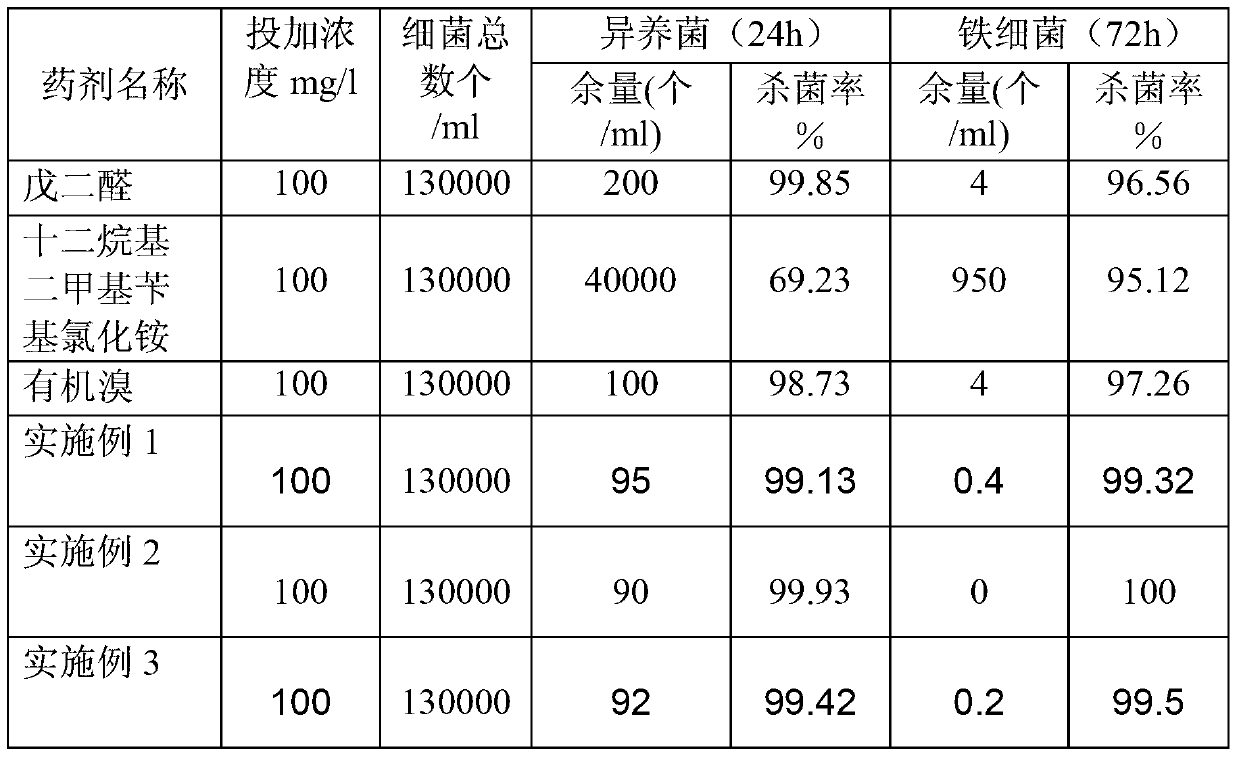

[0033] Above-mentioned embodiment carries out sterilizing performance comparative experiment with bactericides such as glutaraldehyde, lauryl dimethyl benzyl ammonium chloride, organic bromide, and test result is as follows:

[0034]

[0035] The above comparative experiments can be obtained that the bactericidal algicide according to the present invention has a better bactericidal effect than a single agent when the same dosage is used, and the ratio of the embodiment 2 has a better bactericidal effect.

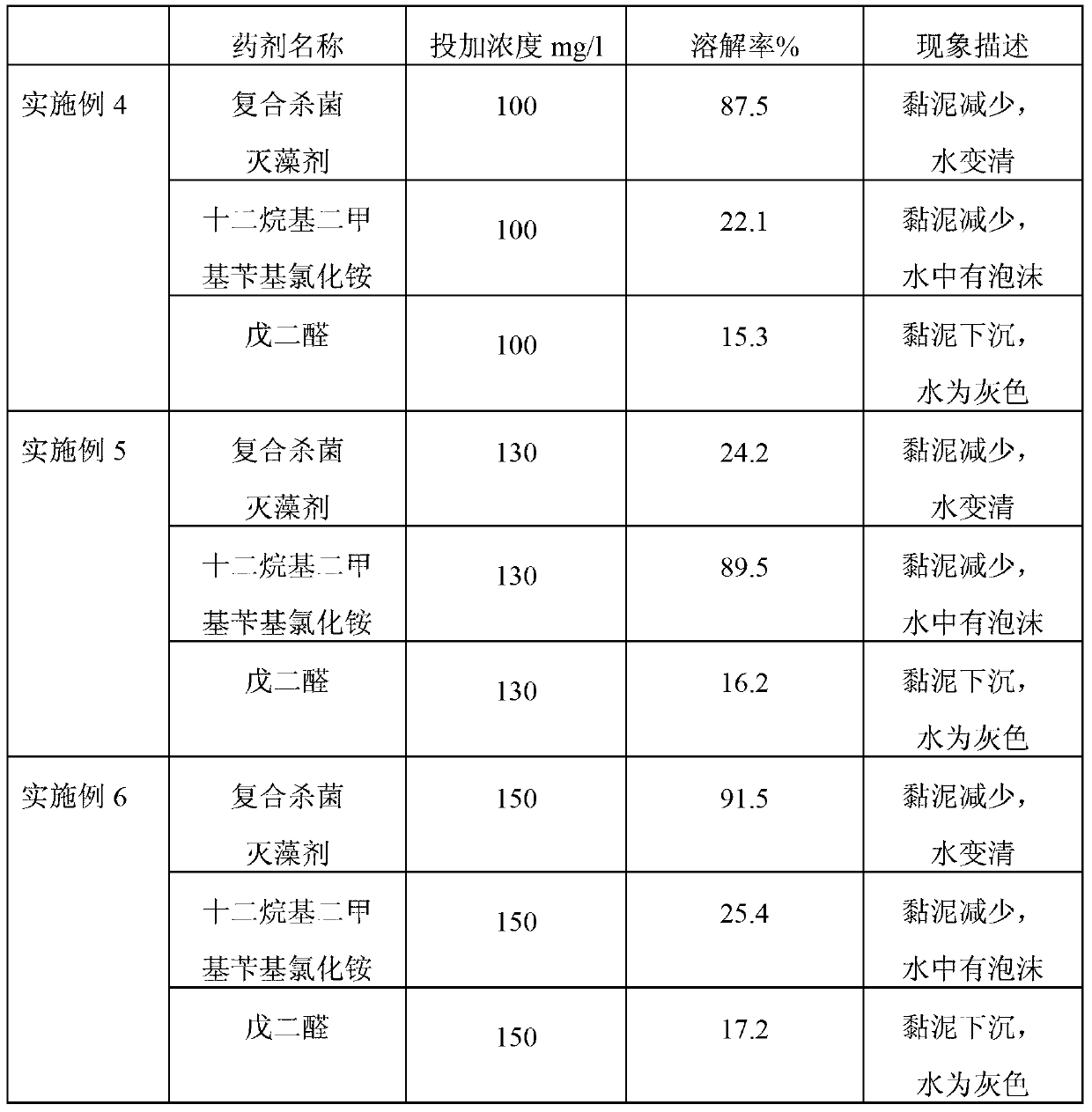

[0036] The slime stripping experiment was carried out us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com