Cetirizine hydrochloride tablet and preparation method thereof

A technology of cetirizine hydrochloride and rizine tablets, which can be applied in the directions of pill delivery, pharmaceutical formulations, and medical preparations with inactive ingredients, etc., can solve problems such as corrosion, inability to effectively solve equipment, and difficulty in drug packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

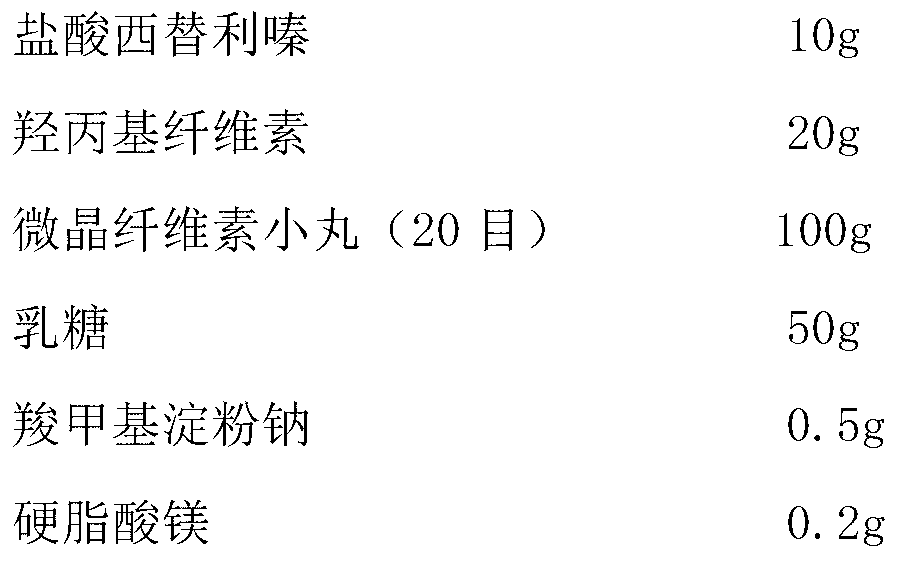

Embodiment 1

[0021]

[0022] Preparation Process:

[0023] (1) Dissolve cetirizine hydrochloride and hydroxypropyl cellulose in 50mL ethanol, add microcrystalline cellulose pellets, stir, dry to remove ethanol, hydroxypropyl cellulose is coated with cetirizine hydrochloride and adheres to the blank pellet surface;

[0024] (2) The drug-loaded pellets obtained in step (1) are uniformly mixed with lactose, sodium carboxymethyl starch and magnesium stearate, and directly compressed into tablets.

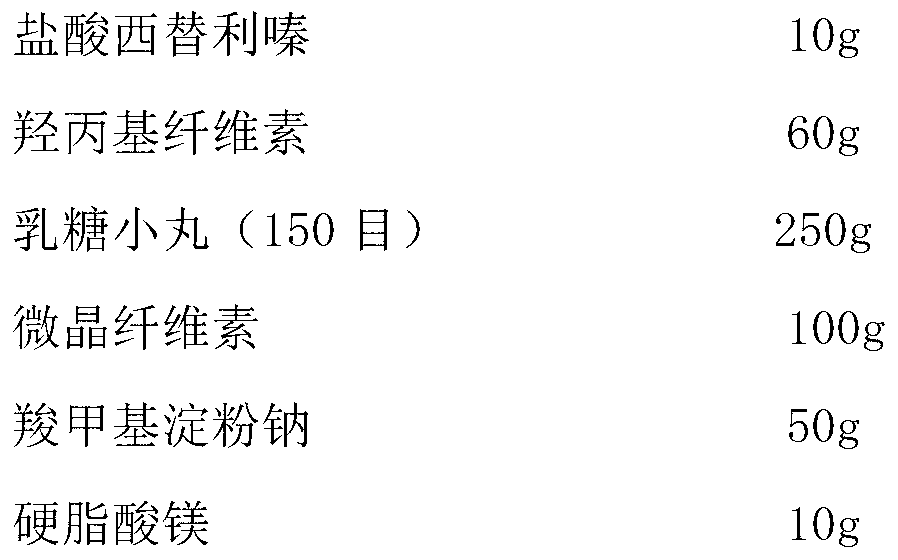

Embodiment 2

[0026]

[0027] Preparation Process:

[0028] (1) Dissolve cetirizine hydrochloride and hydroxypropyl cellulose in 120mL ethanol, add lactose pellets, stir, dry to remove ethanol, hydroxypropyl cellulose is coated with cetirizine hydrochloride and adheres to the surface of blank pellets;

[0029] (2) The drug-loaded pellets obtained in step (1) are uniformly mixed with microcrystalline cellulose, sodium carboxymethyl starch, and magnesium stearate, and directly compressed into tablets.

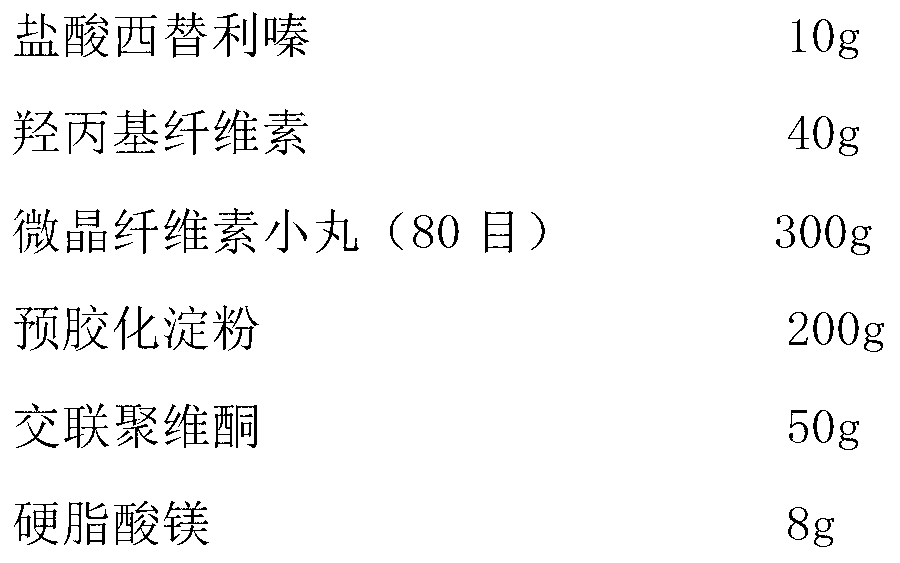

Embodiment 3

[0031]

[0032] Preparation Process:

[0033] (1) Dissolve cetirizine hydrochloride and hydroxypropyl cellulose in 120mL ethanol, add microcrystalline cellulose pellets, stir, dry to remove ethanol, hydroxypropyl cellulose is coated with cetirizine hydrochloride and adheres to the blank pellet surface;

[0034] (2) The drug-loaded pellets obtained in step (1) are uniformly mixed with pregelatinized starch, crospovidone, and magnesium stearate, and directly compressed into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com