Controllably biodegradable poly(lactic-co-glycolic acid) (PLGA) bore gradient membrane and preparation process thereof

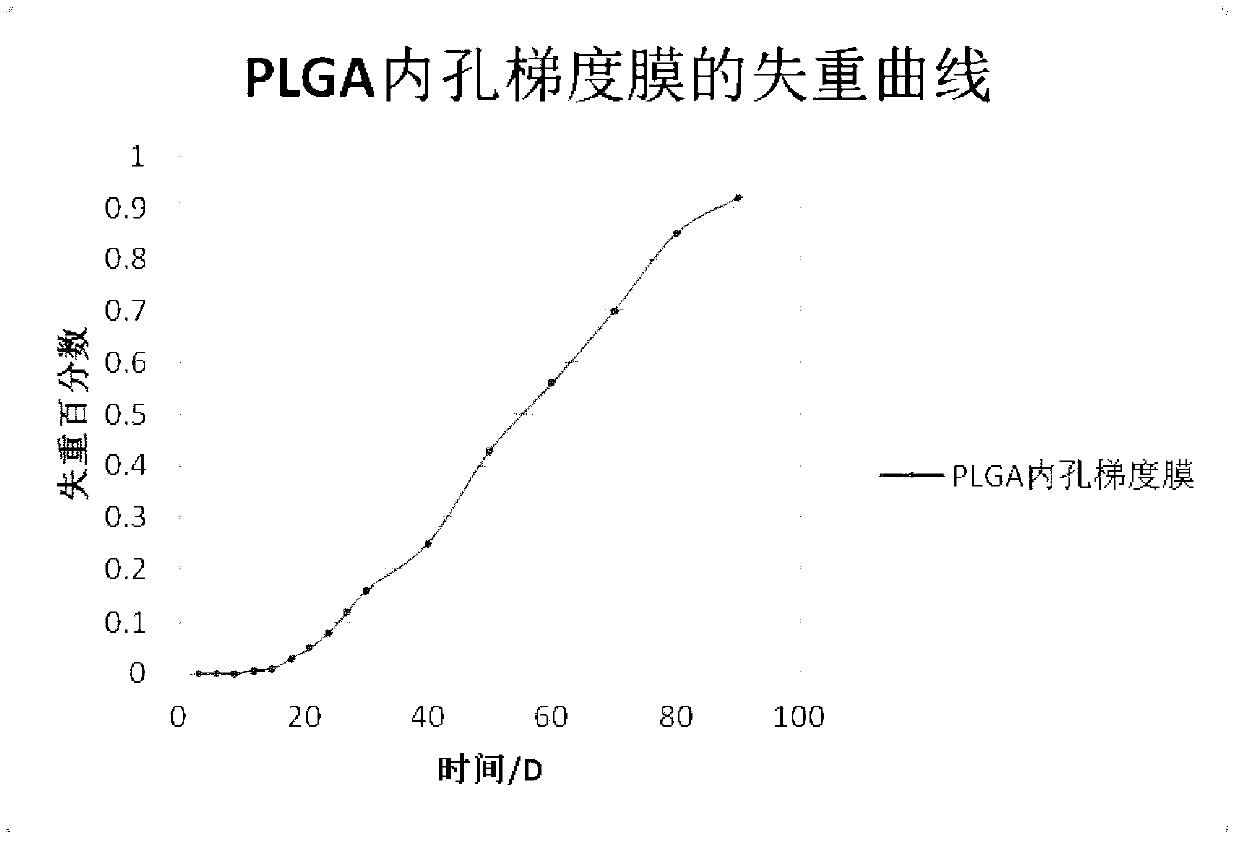

A PLGA and biodegradation technology, applied in the field of biodegradable materials and their preparation, can solve the problems such as the degradation behavior of PLGA series and porous membranes, which cannot meet the requirements of micro-assisted support and rapid degradation, and shortened mechanical strength infiltration time, etc. Achieve the effect of smooth and stable overall degradation curve without burst release, controllable degradation speed and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A controllable biodegradable PLGA inner pore gradient membrane, such as figure 1 As shown, the PLGA inner porous gradient membrane has a centrosymmetric structure with a smooth exterior and a porous interior, and is composed of the following seven layers of films with a thickness of 10-50 μm and equal sizes and thicknesses arranged and pressed sequentially: PLGA5050 film 1, porous PLGA6535 film 2. Porous PLGA7525 film 3, porous PLGA8515 film 4, porous PLGA7525 film 3, porous PLGA6535 film 2 and PLGA5050 film 1.

[0040]Among them, the PLGA5050 film is made of PLGA5050 by solvent casting; the porous PLGA6535 film, porous PLGA7525 film and porous PLGA8515 film are respectively made of porous PLGA6535, porous PLGA7525 and porous PLGA8515 by particle leaching. PLGA5050 is formed by the copolymerization of lactic acid and glycolic acid with a weight ratio of 50:50; porous PLGA6535 is formed by the copolymerization of lactic acid and glycolic acid with a weight ratio of 65:35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com