Preparation of soybean anti-fatigue biological active peptide

A bioactive peptide and anti-fatigue technology, applied in the field of plant protein extraction and processing, can solve the problems of low anti-fatigue activity, high cost, and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

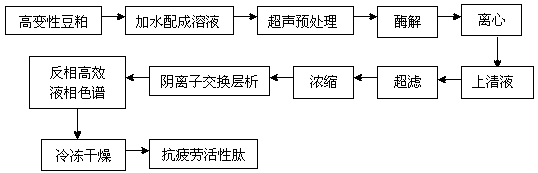

[0013] A preparation of soybean anti-fatigue bioactive peptide, using highly denatured soybean meal as raw material, adding water to prepare a mixed solution with a substrate concentration of 6-10%, and performing ultrasonic pretreatment on the mixed solution, the ultrasonic power is 300-500W, The ultrasonic time is 10-30min, and the ultrasonic temperature is 45-55°C; neutral protease is added to the treated mixed solution for enzymolysis to obtain an enzymolysis solution. The enzymolysis time is 3-5h, and the amount of enzyme added is 28000-36000U / g substrate; after enzymolysis, the enzymolysis solution was subjected to ultrafiltration treatment by membrane separation technology to obtain bioactive peptides with high peptide content and molecular weight less than 5 kDa, which were then separated and purified by anion exchange chromatography and reversed-phase high performance liquid chromatography. Finally, the soybean anti-fatigue bioactive peptide was obtained by freeze-dry...

Embodiment 1

[0018] Embodiment 1: the screening experiment of ultrasonic pretreatment optimal parameter

[0019] 1 Materials and methods

[0020] 1.1 Materials and reagents

[0021]

[0022] 1.2 Main instruments and equipment

[0023]

[0024] 1.3 Test method

[0025] 1.3.1 Process flow

[0026] Highly denatured soybean meal→add water to make a solution→ultrasonic pretreatment→enzymolysis→inactivate enzyme→cooling→adjust pH to acidity→centrifuge→supernatant→freeze-drying→antioxidant active peptide

[0027] 1.3.2 Determination of the free radical scavenging rate of diphenylpicryl (DPPH)

[0028] Take 1.00 mL of the hydrolyzate, add 4.00 mL of 100 μmol L-1 DPPH ethanol solution and mix well, keep it in the dark for 30 min, adjust to zero with the original solvent, measure the absorbance at 517 nm and record it as A i ; Add 1.00 mL of solvent to 4.00 mL of 100 μmol L-1 DPPH solution in the same way and mix well, measure the absorbance as A c ; Take 1.00 mL of hydrolyzate and add 4...

Embodiment 2

[0048] Embodiment 2: the screening test of optimal parameter of enzymatic hydrolysis process

[0049] 1 Materials and methods

[0050] 1.1 Materials and reagents

[0051]

[0052] 1.2 Main instruments and equipment

[0053]

[0054] 1.3 Test method

[0055] 1.3.1 Process flow

[0056] Highly denatured soybean meal→add water to make a solution→ultrasonic pretreatment→enzymolysis→inactivate enzyme→cooling→adjust pH to acidity→centrifuge→supernatant→freeze-drying→antioxidant active peptide

[0057] 1.3.2 Determination of the free radical scavenging rate of diphenylpicryl (DPPH)

[0058] Take 1.00 mL of the hydrolyzate, add 4.00 mL of 100 μmol L-1 DPPH ethanol solution and mix well, keep it in the dark for 30 min, adjust to zero with the original solvent, measure the absorbance at 517 nm and record it as A i ; Add 1.00 mL of solvent to 4.00 mL of 100 μmol L-1 DPPH solution in the same way and mix well, measure the absorbance as A c ; Take 1.00 mL of hydrolyzate and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com