Silicon-carbon composite material and preparation method thereof, and lithium ion battery

A silicon-carbon composite material and composite technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex synthesis process, time-consuming and labor-intensive, difficult to large-scale production, etc., to reduce volume expansion, shorten diffusion path, extend The effect of charge-discharge cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

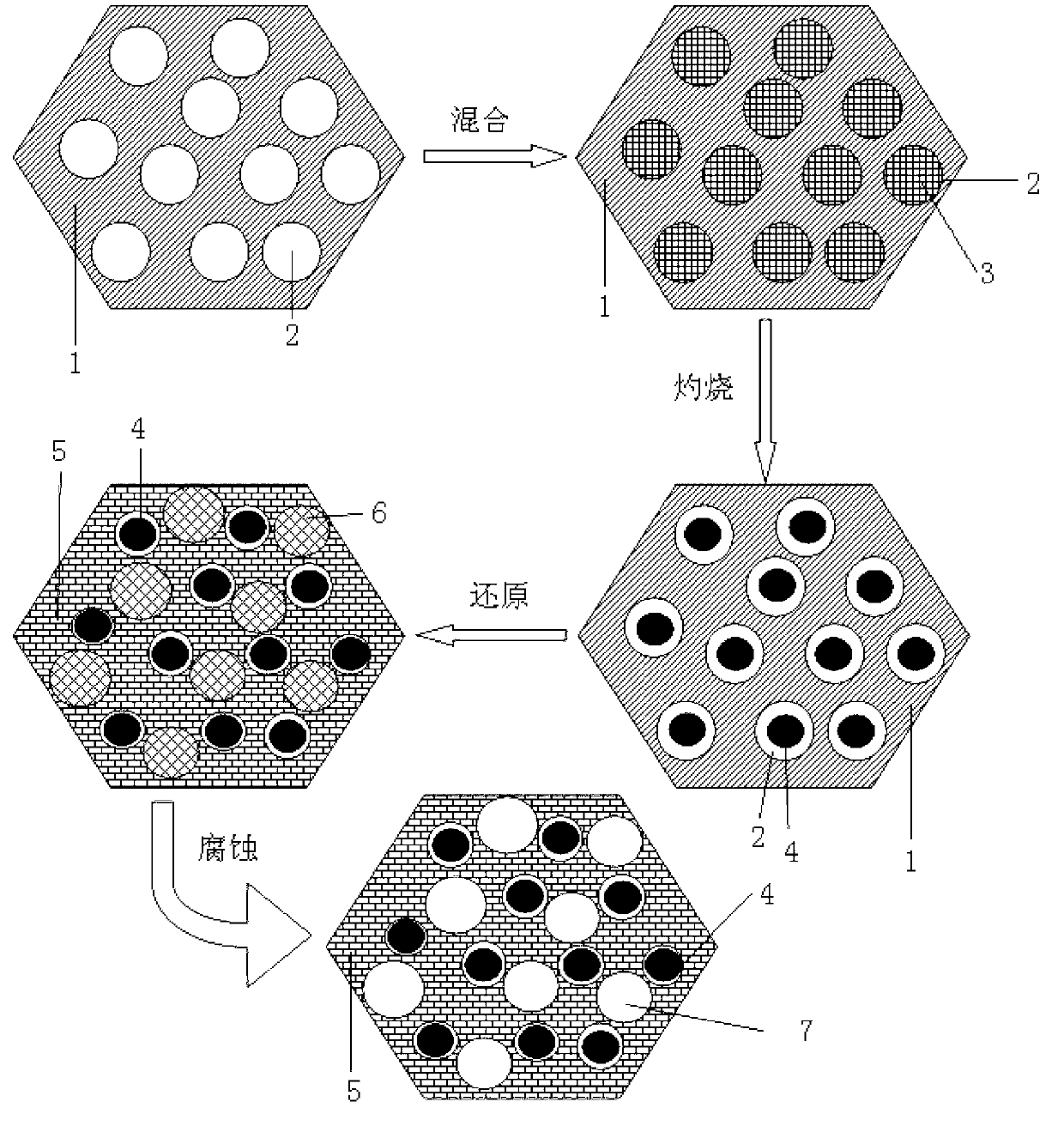

[0033] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0034] (1) Add a catalytic amount of concentrated sulfuric acid (generally 0.01-0.15 grams of concentrated sulfuric acid per gram of sucrose) into the sucrose solution, and then add a solution with a specific surface area of 700m 2 / g of silica gel (the main component is porous silica), wherein the mass ratio of silica gel to sucrose is 1:1, stir evenly, and evaporate to dryness. Then transfer to a crucible and burn under the protection of nitrogen atmosphere. The burning temperature is 600°C and the burning time is 12 hours to obtain porous carbon-coated silica, thereby forming nano-carbon and silicon dioxide interconnected. composite structure.

[0035] (2) Weigh potassium particles (particle size 1mm), wherein the amount of potassium particles is 100% of the theoretical amount that can completely reduce the silicon dioxide in step (1). Mix the po...

Embodiment 2

[0044] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0045] (1) Add a catalytic amount of concentrated sulfuric acid (generally 0.01 to 0.15 grams of concentrated sulfuric acid per gram of lactic acid or glucose) into the solution of lactic acid and glucose (where the mass ratio of lactic acid and glucose is 1:1), and then Adding a specific surface area of 500m 2 / g of fumed silica powder, wherein the ratio of the mass of fumed silica powder to the sum of the mass of lactic acid and glucose is 2:1, stir evenly, and evaporate to dryness. Transfer to a crucible again, and burn under the protection of a helium atmosphere. The burning temperature is 950 ° C, and the burning time is 0.5 hours, so that porous carbon is coated on the fumed silica, and the carbon in the carbon layer The particle size is nanoscale, and porous carbon-coated fumed silica is obtained.

[0046] (2) Weigh magnesium particles (parti...

Embodiment 3

[0050] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0051] (1) Add quartz sand with an average particle size of 5 microns to the starch solution, wherein the mass ratio of starch to quartz sand is 4:1, put it into a hydrothermal reaction kettle and heat it to 600°C for 2 hours. Then transferred to the crucible, burning under the protection of argon atmosphere, the burning temperature is 400 ℃, and the burning time is 24 hours, so that the porous carbon is coated on the surface of the quartz sand, and the carbon particles in the carbon layer The diameter is nanoscale, and the porous carbon-coated quartz sand is obtained.

[0052] (2) Weigh lithium and sodium particles (particle size 1mm) (the mass ratio of lithium and sodium is 2:1), wherein the amount of lithium and sodium particles is such that all the quartz sand in step (1) can be reduced 120% of the theoretical usage. Mix the particles of lithium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com