Preparation method of carbon-coated lithium iron phosphate material with carbon black as carbon source

A carbon-coated lithium iron phosphate and carbon source technology, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of low electronic conductivity of lithium iron phosphate and slow diffusion of lithium ions, and improve safety and battery performance , low cost and easy synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Ferric nitrate ( Fe(NO 3 ) 3 9H 2 O) 3.9400g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.3452g, citric acid ( C 6 h 8 o 7 ·H 2 O) 2.3155g are mixed to form a homogeneous mixture;

[0021] (2) Slowly add lithium acetate (LiAc·2H 2 O) 1.4143 g of solution to form a mixed material;

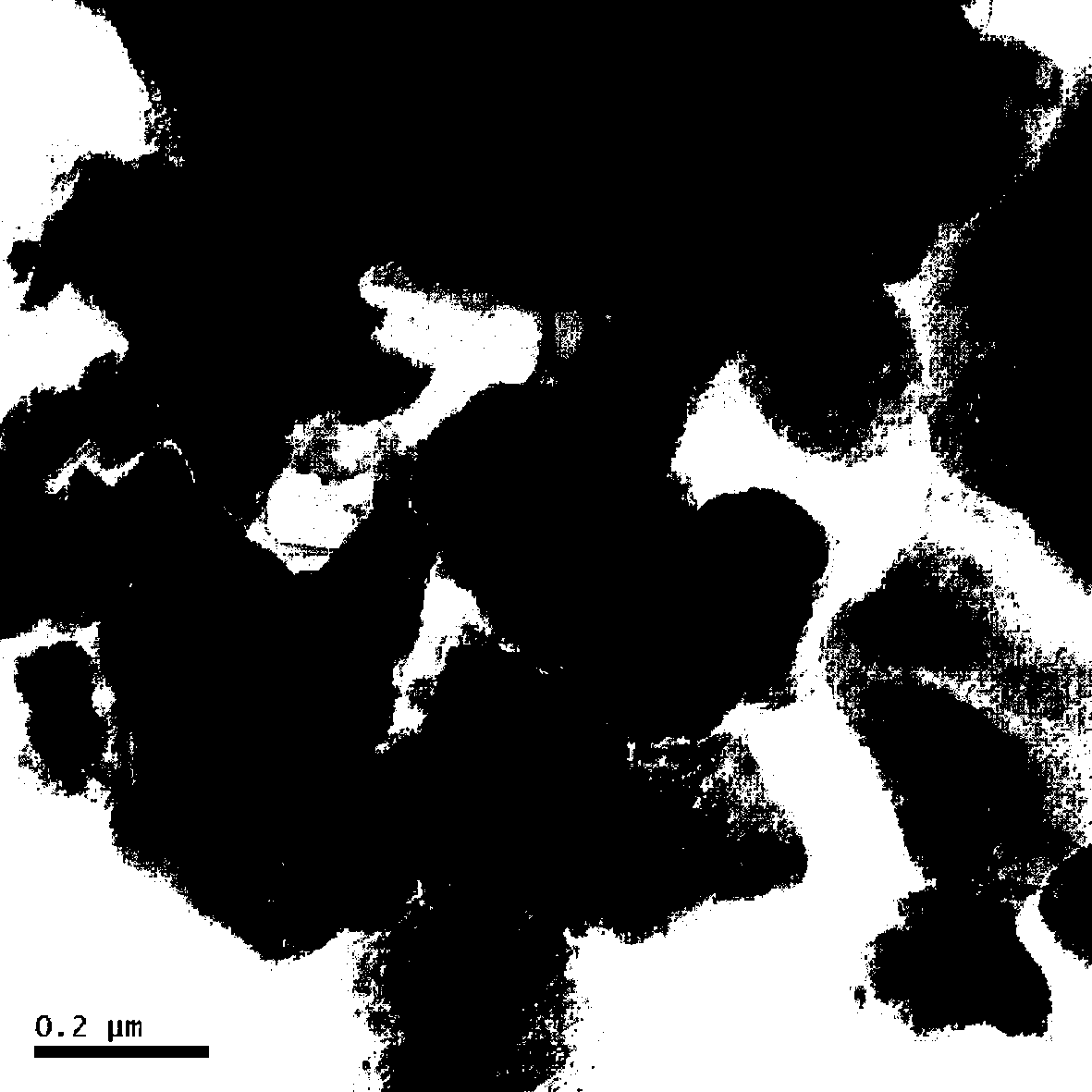

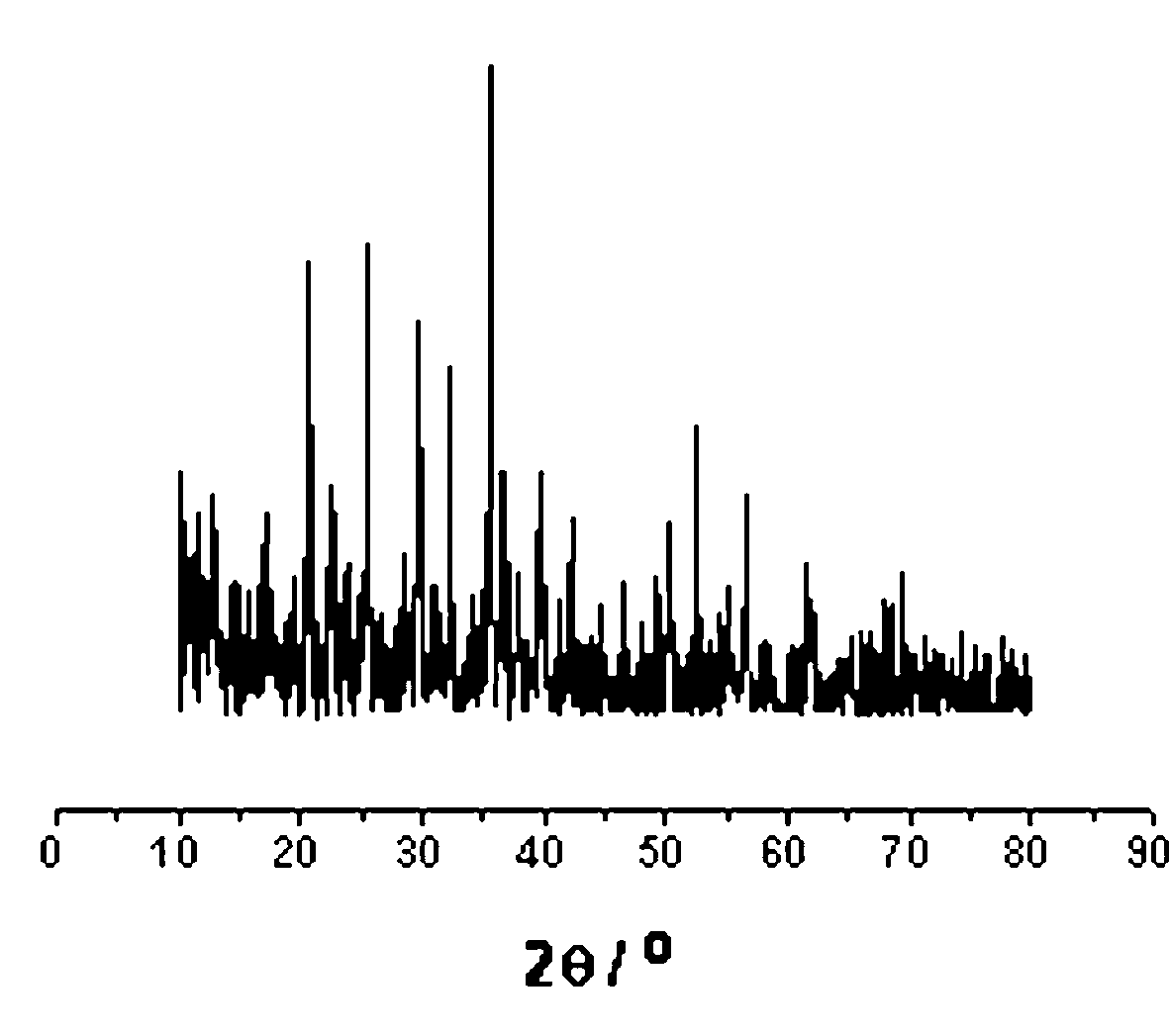

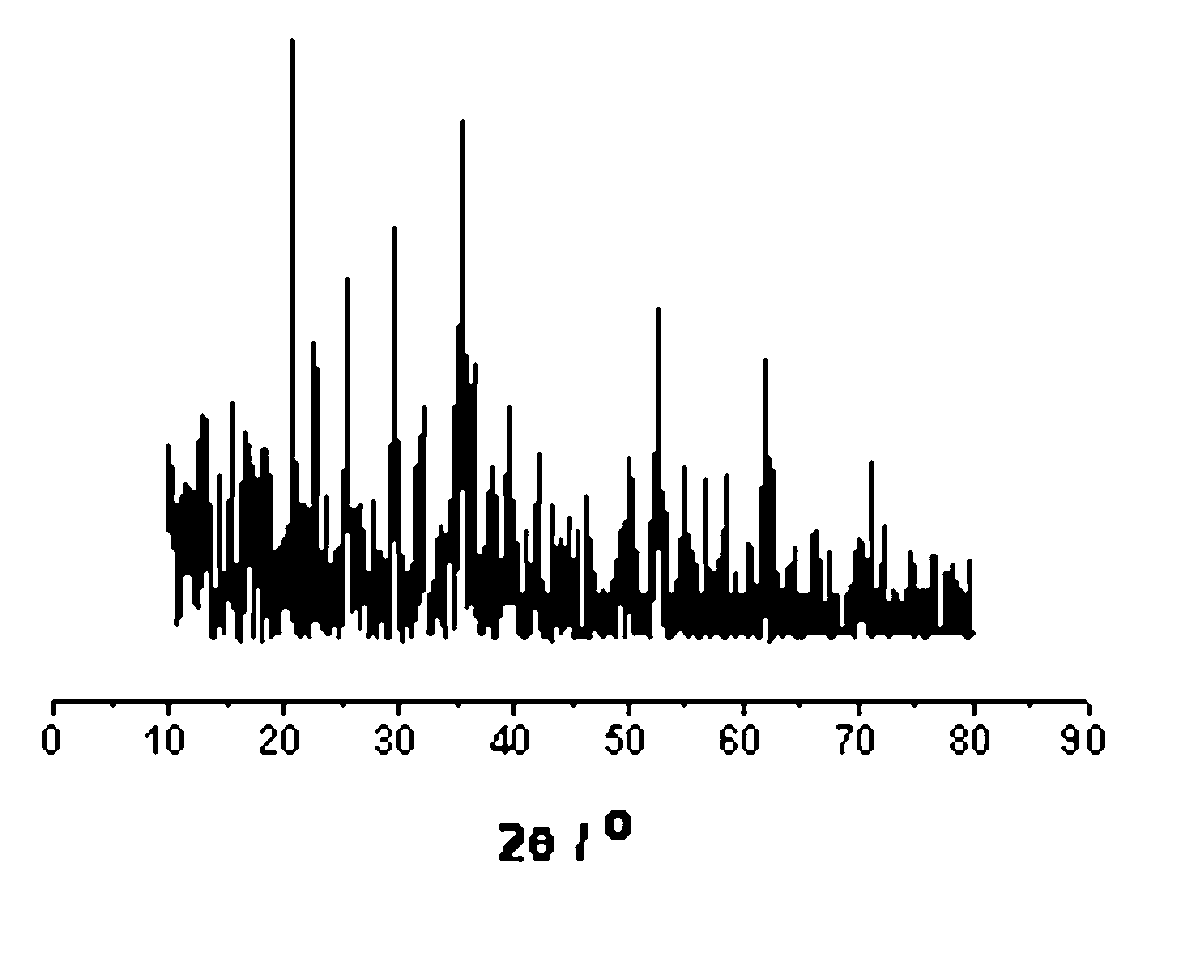

[0022] (3) Heat the mixed material to 60°C. When the solution starts to become turbid, impregnate the mesoporous carbon CMK-3 into the solution and stir for 30 minutes, then sonicate for 10 minutes, stir and ultrasonically cycle 3 times in turn until the solution becomes It is muddy; (4) Ultrasonicate and stir the obtained muddy material again for 5 times, and put it in an oven with a constant temperature of 120°C for drying;

[0023] (5) Grinding the dried material for 12 hours;

[0024] (6) Put the obtained powder material into a tube furnace with argon gas, and calcined at three stages of temperature, 220°C for 1 hour, 350°C for 2 hours, and 700°C for 6 hours to obtain...

Embodiment 2

[0028] (1) Ferric nitrate ( Fe(NO 3 ) 3 9H 2 O) 4.3856g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.2539g, citric acid ( C 6 h 8 o 7 ·H 2 O) 2.4231 g are mixed to form a homogeneous mixture;

[0029] (2) Slowly add lithium acetate (LiAc·2H 2 O) 1.3652 g of solution to form a mixed material;

[0030] (3) Heat the mixed material to 70°C. When the solution starts to become turbid, impregnate the mesoporous carbon CMK-3 into the solution and stir for 30 minutes, then sonicate for 10 minutes, and then stir and sonicate for 5 times until the solution becomes turbid. It is muddy; (4) Ultrasonicate and stir the obtained muddy material again for 5 times, and put it into an oven with a constant temperature of 130°C for drying;

[0031] (5) Grinding the dried material for 20 hours;

[0032](6) Put the obtained powder material into a tube furnace with argon gas, and calcine it at three stages of temperature, 220°C for 1 hour, 350°C for 3 hours, and 700°C for 7 hours to o...

Embodiment 3

[0036] (1) Ferric nitrate ( Fe(NO 3 ) 3 9H 2 O) 3.5266g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.9421g, citric acid ( C 6 h 8 o 7 ·H 2 O) 2.5324 g are mixed to form a homogeneous mixture;

[0037] (2) Slowly add lithium acetate (LiAc·2H 2 O) 1.7421 g of solution to form a mixed material;

[0038] (3) Heat the mixed material to 80°C. When the solution starts to become turbid, impregnate the mesoporous carbon CMK-3 into the solution and stir for 30 minutes, then sonicate for 10 minutes, stir and ultrasonically cycle 4 times until the solution turns It is muddy; (4) Ultrasonicate and stir the obtained muddy material again for 5 times, and put it in an oven with a constant temperature of 140°C for drying;

[0039] (5) Grinding the dried material for 18 hours;

[0040] (6) Put the obtained powder material into a tube furnace filled with argon, and calcined at three stages of temperature, 220°C for 1 hour, 350°C for 2 hours, and 700°C for 8 hours to obtain carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com