High-performance multi-azo brown reactive dye, as well as synthesis and application of mixture of high-performance multi-azo brown reactive dye

A technology of reactive dyes and polyazo, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems of reducing printing and dyeing costs, and achieve increased directness, good dyeing depth and lifting power, and excellent wet processing The effect of fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

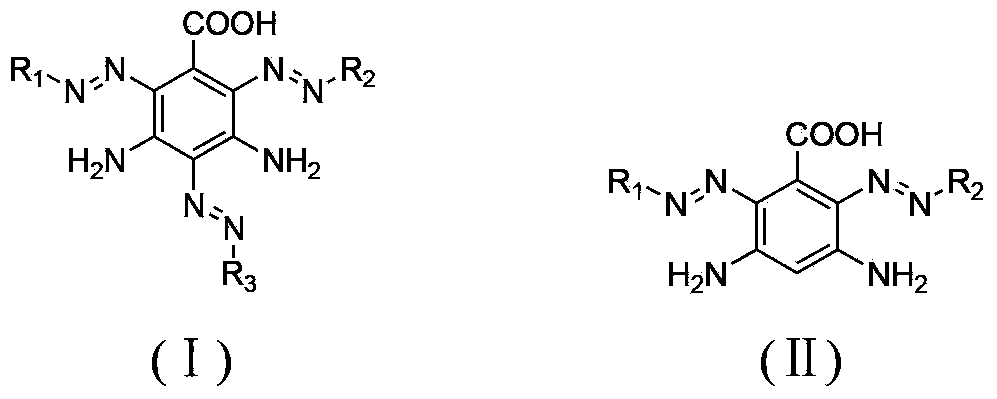

[0064] The preparation of embodiment 1 polyazo brown dye Ⅰ-1

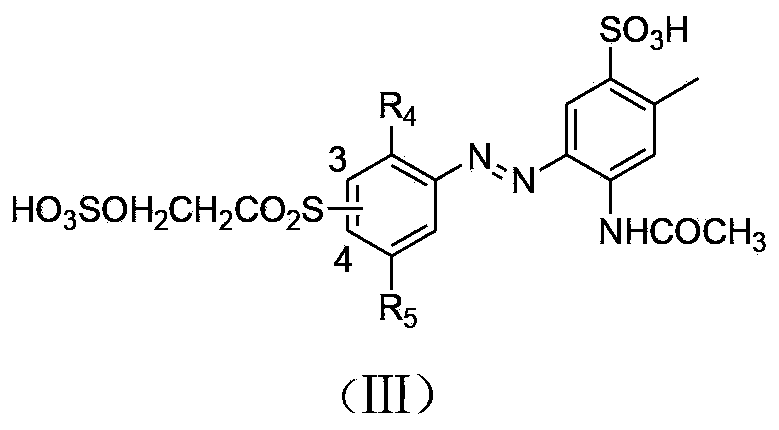

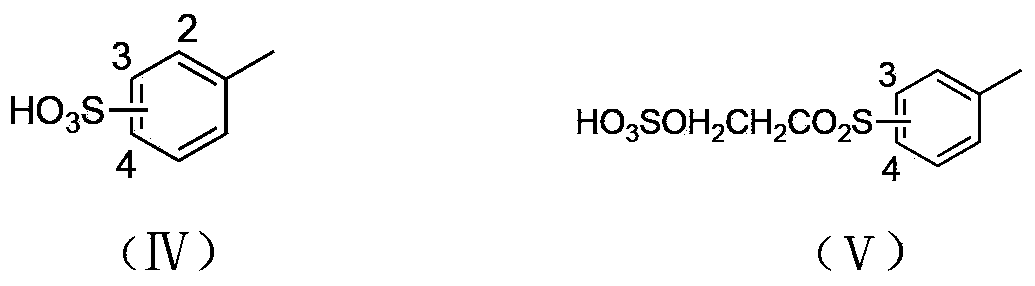

[0065] In a 1000 ml beaker, add 200 parts of water, 52.3 parts of formula III-1 compound (R 4 , R 5 hydrogen), 0.1 part of dispersant, stirring and beating for 1 hour, adding 35 parts of 30% hydrochloric acid, adding 23 parts of 30% sodium nitrite solution at 0-5°C for diazotization reaction for 2 hours, and adding amino Sulfonic acid destroys excess nitrous acid, then add 15.2 parts of 15% 3.5-diaminobenzoic acid solution, heat up to 10-15°C, adjust pH=1-2 with 15% sodium acetate solution, and react 4-6 Hours, when there is no diazonium salt, it is the end point, and it is ready for use.

[0066] In a 1000ml beaker, add 300 parts of water, 56.2 parts of formula para-ester, 0.1 part of dispersant, stir and beat for 1 hour, add 60 parts of 30% hydrochloric acid, and add 46 parts of 30% nitrous acid at 0-5°C The sodium solution was diazotized for 2 hours. After reaching the end point, sulfamic acid was added to de...

Embodiment 2-24

[0068] Example 2-24 Preparation of polyazo brown dyes I-2 to I-12 and preparation of other structures

[0069] Change different R with reference to the method of Example 1 1 , R 2 , R 3 The diazo component can be used to obtain dyes I-2~I-12 and other polyazo brown dyes.

[0070]

[0071]

[0072]

[0073]

[0074] Only some dyes of the general formula I are exemplified here, and those skilled in the art can foresee that dyes I with different substituents can be obtained by using different reactants to finally realize the present invention.

Embodiment 25

[0075] The preparation of embodiment 25 polyazo brown dye II-1

[0076] In a 1000 ml beaker, add 200 parts of water, 52.3 parts of formula III-1 compound (R 4 , R 5 hydrogen), 0.1 part of dispersant, stirring and beating for 1 hour, adding 35 parts of 30% hydrochloric acid, adding 23 parts of 30% sodium nitrite solution at 0-5°C for diazotization reaction for 2 hours, and adding amino Sulfonic acid destroys excess nitrous acid, then add 15.2 parts of 15% 3.5-diaminobenzoic acid solution, heat up to 10-15°C, adjust pH=1-2 with 15% sodium acetate solution, and react 4-6 Hours, when there is no diazonium salt, it is the end point, and it is ready for use.

[0077] In a 1000ml beaker, add 150 parts of water, 28.1 parts of formula para-ester, 0.1 part of dispersant, stir and beat for 1 hour, add 30 parts of 30% hydrochloric acid, and add 23 parts of 30% nitrous acid at 0-5°C The sodium solution was diazotized for 2 hours. After reaching the end point, sulfamic acid was added to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com