Lubricant for papermaking coating and preparation method of lubricant

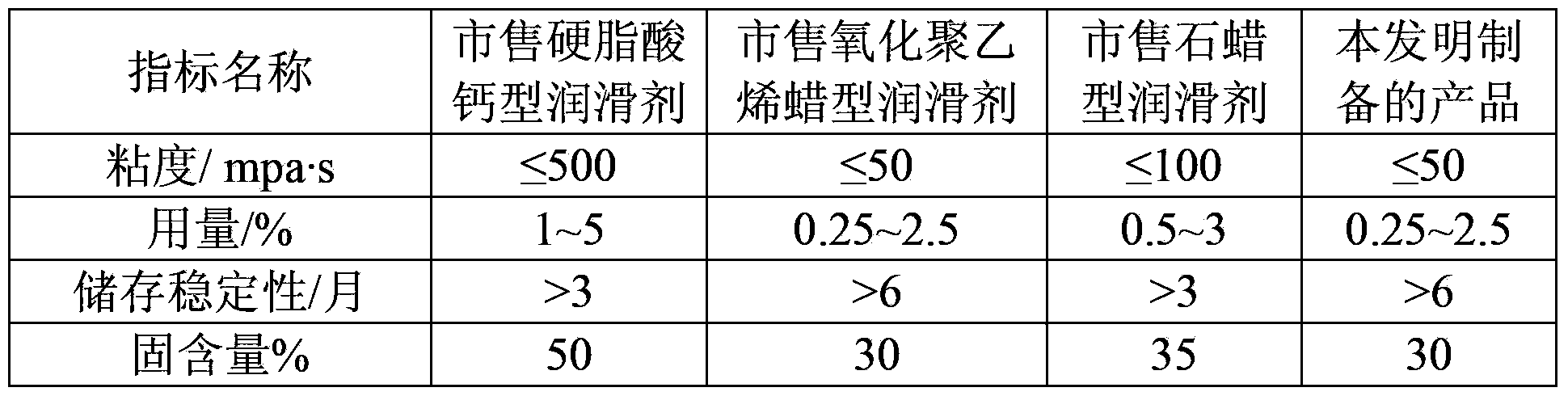

A lubricant and coating technology, used in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of large amount of paraffin emulsion emulsifier, high requirements for preparation conditions, expensive additives, etc., and achieves low cost, harsh process conditions, Improved smoothness and surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

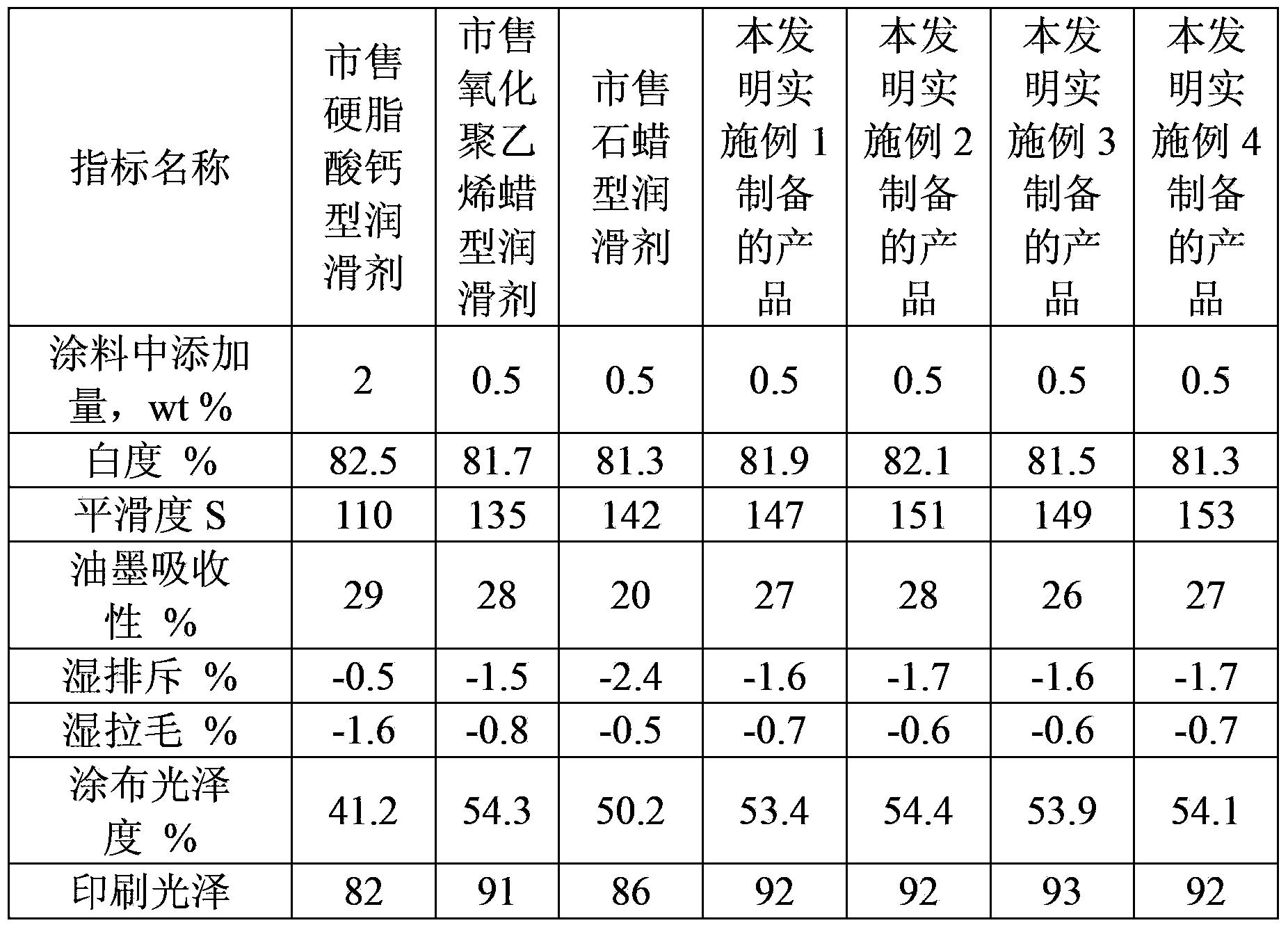

Embodiment 1

[0035] Put 100kg of paraffin wax and 3kg of 12-hydroxystearic acid into the white steel tower together, heat up the temperature, and when the raw materials melt, pass 10m into the tower 3 / h air, continue to heat up, when the temperature reaches 120°C, slowly add 1kg of potassium permanganate to carry out the oxidation reaction, stop the reaction after 4 hours and lower the temperature, when the temperature is 90°C, add 5kg of fatty alcohol polyoxyethylene ether ( O-10), 4kg fatty alcohol polyoxyethylene ether (O-20), 1kg sodium dodecylbenzenesulfonate and 6kg triethanolamine, after stirring for 20 minutes, add 280kg water, at 85~95℃, at 600r Stir at a speed of 1 / min for 30 minutes. After the emulsification is completed, the temperature of the system is lowered to 50°C. The cover is opened and the material is discharged to obtain a special lubricant modified paraffin wax microemulsion for papermaking coating.

[0036] The lubricant has a solid content of 30.5%, an average part...

Embodiment 2

[0038]Add 100kg of paraffin into the reaction tower, heat up the temperature, when the raw material melts, pass 20m into the tower 3 / h of air, continue to heat up, when the temperature reaches 130°C, slowly add 12kgH 2 0 2 (content 50%), carry out oxidation reaction, stop the reaction after 5 hours and lower the temperature, when the temperature is 90°C, add 12kg nonylphenol polyoxyethylene ether (TX-10), 1kg sodium dodecyl sulfate and 3kg di For ethanolamine, after stirring for 25 minutes, add 280kg of water and stir for 40 minutes at 85-95°C at a speed of 700r / min. After the emulsification is completed, the temperature of the system is lowered to 50°C, and the cover is opened and the material is discharged to obtain a paper-making coating. Special lubricant modified paraffin microemulsion.

[0039] The lubricant has a solid content of 30.3%, an average particle size of 0.137 μm, and a viscosity of 38 mPa·s. After the emulsion was centrifuged at 3000 rpm, there was no str...

Embodiment 3

[0041] Add 100kg of paraffin into the reaction kettle, heat up the temperature, and when the raw material melts, pass it into the tower for 30m 3 / h of air, continue to heat up, when the temperature reaches 140°C, slowly add 0.4kg of manganese sulfate and 0.2kg of caustic soda to carry out the oxidation reaction, stop the reaction after 6 hours and lower the temperature, when the temperature is 90°C, add 5kg of isomeric polyalcohol Oxyethylene ether (E1310), 10kg sorbitan monooleate (Span-80) and 4kg polyethylene glycol 200, after stirring for 20 minutes, add 250kg of water, at 85~95℃, at 700r / min Stir at high speed for 35 minutes. After the emulsification is completed, the temperature of the system drops to 50°C. The lid is opened and the material is discharged to obtain a special lubricant modified paraffin wax microemulsion for papermaking coating.

[0042] The lubricant has a solid content of 29.8%, an average particle size of 0.103 μm, and a viscosity of 29 mPa·s. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com