Coated antenna for microwave reader-writer of ETC (electronic toll collection) system

An electronic non-stop and charging system technology, applied in the field of antennas, can solve the problems of high side lobe level, lane interference, main lobe beam width, etc., and achieve the effect of solving adjacent channel interference, sharpening the beam, and improving the gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

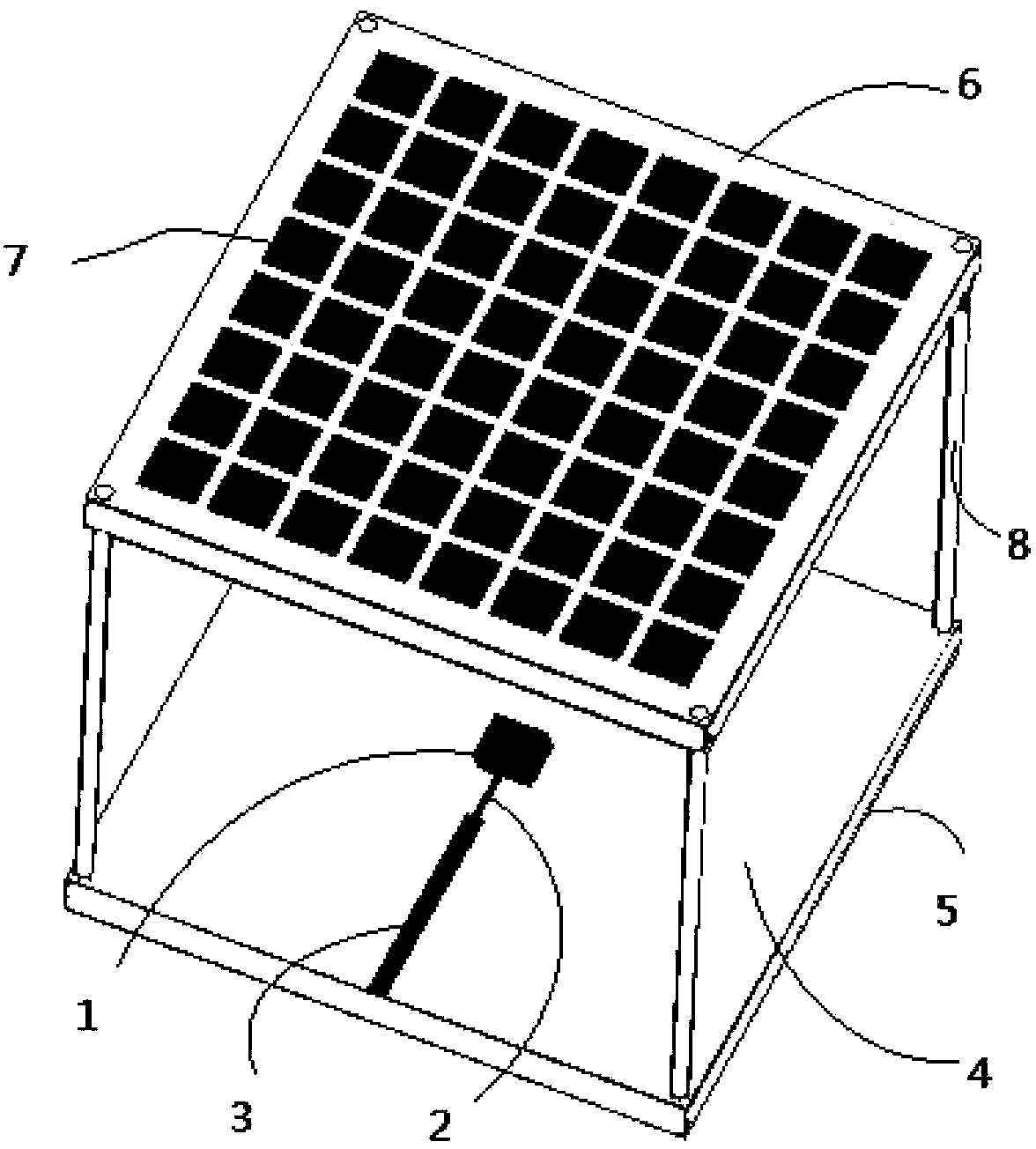

[0027] refer to figure 1 , the present invention is used for the cladding antenna of microwave reader-writer of electronic non-parking toll collection system comprising: circularly polarized radiation patch 1, impedance transformation line 2, 50 ohm microstrip feeder line 3, dielectric substrate 4, ground plate 5 and frequency selection Surface cladding 6, square metal units 7 uniformly arranged two-dimensionally and periodically. The circularly polarized radiation patch 1 is placed in the center of the dielectric substrate 4 and connected to the 50-ohm microstrip feeder 3 through the impedance transformation line 2 to achieve impedance matching. The frequency selective surface coating 6 is fixed directly above the circularly polarized radiation patch 1 through an insulating support 8 and aligned with the four corners of the dielectric substrate 4 .

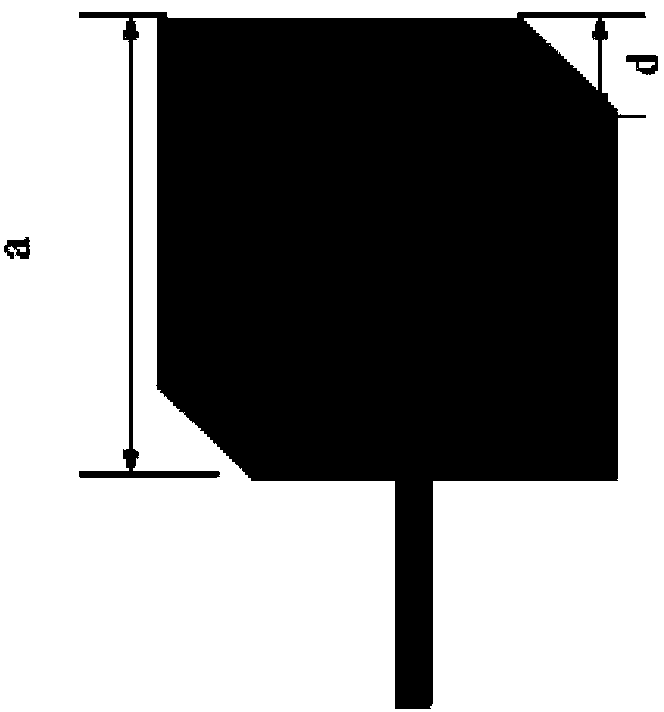

[0028] The approximate value of the side length a of the circularly polarized radiation patch 1 can be determined by the follo...

Embodiment 2

[0044] see figure 1 , this embodiment includes: a circularly polarized radiation patch 1, an impedance transformation line 2, a 50-ohm microstrip feeder 3, a dielectric substrate 4, a ground plate 5, and a frequency-selective surface coating 6, and a uniform two-dimensional periodic arrangement of square metal units 7. The circularly polarized radiation patch 1 is placed in the center of the dielectric substrate 4 and connected to the 50-ohm microstrip feeder 3 through the impedance transformation line 2 to achieve impedance matching. The frequency selective surface coating 6 is fixed directly above the circularly polarized radiation patch 1 through an insulating support 8 and aligned with the four corners of the dielectric substrate 4 .

[0045] The structure of this embodiment is the same as that of Embodiment 1, but the parameters are different. The side length a of the circularly polarized radiation patch 1 is 15.4 mm, the cut-off side length d is 3 mm, the side length b...

Embodiment 3

[0047] see figure 1 , this embodiment includes: a circularly polarized radiation patch 1, an impedance transformation line 2, a 50-ohm microstrip feeder 3, a dielectric substrate 4, a ground plate 5, and a frequency-selective surface coating 6, and a uniform two-dimensional periodic arrangement of square metal units 7. The circularly polarized radiation patch 1 is placed in the center of the dielectric substrate 4 and connected to the 50-ohm microstrip feeder 3 through the impedance transformation line 2 to achieve impedance matching. The frequency selective surface coating 6 is fixed directly above the circularly polarized radiation patch 1 through an insulating support 8 and aligned with the four corners of the dielectric substrate 4 .

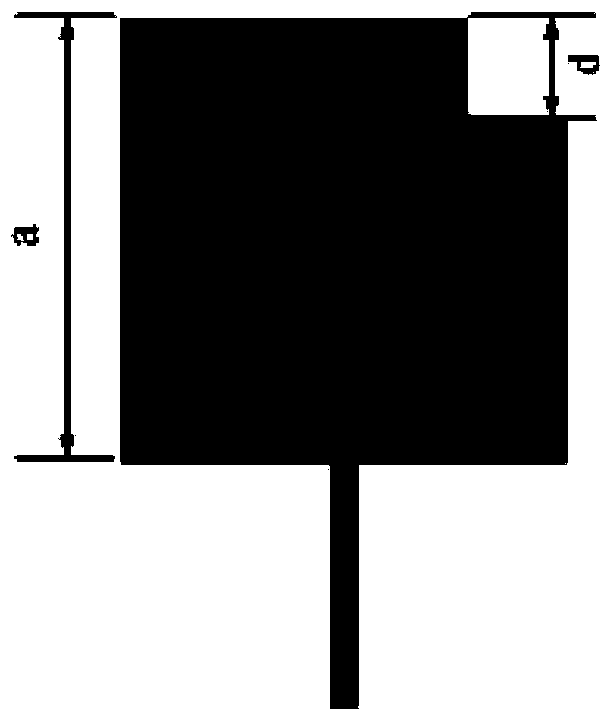

[0048] see image 3 In this embodiment, the circularly polarized radiation patch 1 realizes circular polarization by cutting off a square corner, and the size of the cut off square corner is 1.8 mm. The rest of the structure is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com