Fermented composition of multiple probiotics and composite medicinal and edible fungi, and preparation method and application thereof

A technology of medicinal and edible fungi and fermented composition, which is applied in the application field of health care products or medicines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

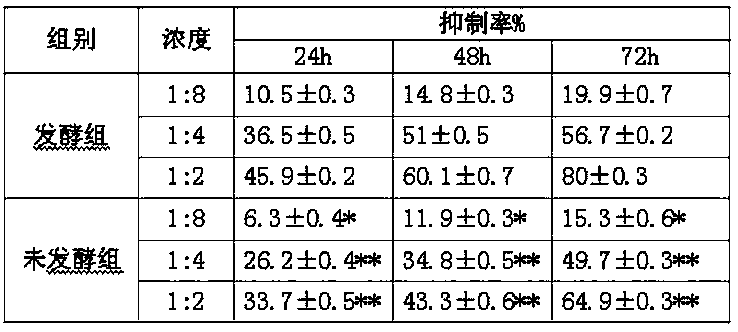

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of the fermented composition of probiotics fermentation Ganoderma lucidum, Agaricus blazei, mushroom, Flammulina velutipes

[0034] Take dried Ganoderma lucidum, Agaricus blazei, shiitake mushrooms, and Flammulina velutipes fruit bodies, and use ordinary crushing technology to pulverize the above fungi for both medicinal and edible purposes. Take fungal powder: Ganoderma lucidum 4.0g, Agaricus blazei 30g, Lentinus edodes 40g, Flammulina velutipes 10g, add drinking water equivalent to 60 times the weight of the composite bacterial powder to the fungus powder, soak for 30 minutes, and heat at 100°C for 1 hour, When the temperature is cooled to about 40°C, add the compound enzyme according to the ratio of 3% (volume ml / weight g) of the enzyme to the compound bacterial powder (cellulase: pectinase: protease = 1:2:1, Taian Xindeli Bioengineering Co., Ltd.), after 3 hours of enzymatic hydrolysis at 37°C~50°C, boil for 10 minutes to inactivate the...

Embodiment 2

[0035] Embodiment 2: Preparation of the fermented composition of probiotic fermented Agaricus blazei, shiitake mushroom, and Flammulina velutipes composite fungal powder

[0036] Take dried Agaricus blazei, shiitake mushrooms, and Flammulina velutipes fruiting bodies, crush them, and the bacteria powder is required to pass through a 65-mesh sieve. Take fungal bacteria powder: Agaricus blazei 20 g, shiitake mushrooms 20 g, Flammulina velutipes 10 g, add 1000ml of drinking water to soak for 1 hour, 100 Heat at ℃ for 1 hour, and when the temperature cools down to about 40℃, add compound enzyme according to the ratio of 3% (volume ml / weight g) of enzyme to compound bacterial powder (cellulase: pectinase: protease = 1:2: 1, produced by Taian Xindeli Bioengineering Co., Ltd.), after 3 hours of enzymatic hydrolysis at 37 ° C ~ 50 ° C, boil for 10 minutes to inactivate the enzyme, and obtain the enzymatic hydrolysis complex polysaccharide extract with residue left. Then add glucose 0....

Embodiment 3

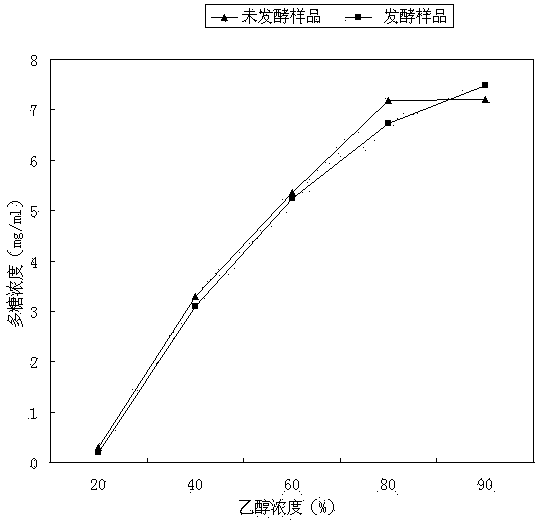

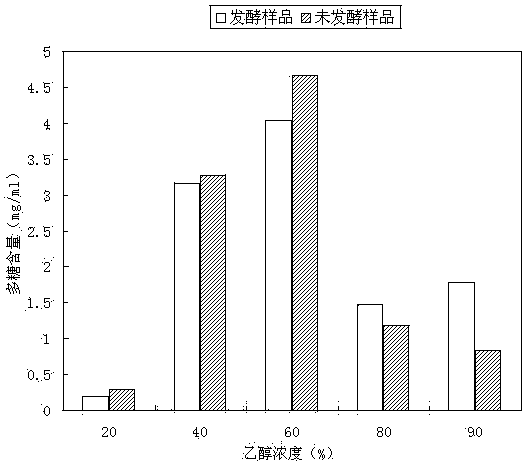

[0037] Example 3: Changes in polysaccharide molecular weight distribution between fermented and unfermented compositions of Agaricus blazei, shiitake mushrooms, and Flammulina velutipes fungal powder compound polysaccharide fermented by intestinal probiotics

[0038] The sample prepared in Example 2 was selected, and the composition without probiotic fermentation was used as a control.

[0039] The purpose of the test is to examine the polysaccharide molecular weight distribution of the compound medicinal and edible fungus after the fermentation and transformation of probiotics. In the polysaccharide extraction experiment, alcohol precipitation is the first step in the separation and purification of polysaccharides, and alcohol precipitation is separated and purified according to the molecular weight. When the concentration of alcohol precipitation is small, the polysaccharides that can be precipitated are often polysaccharides with larger molecular weights. The concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com