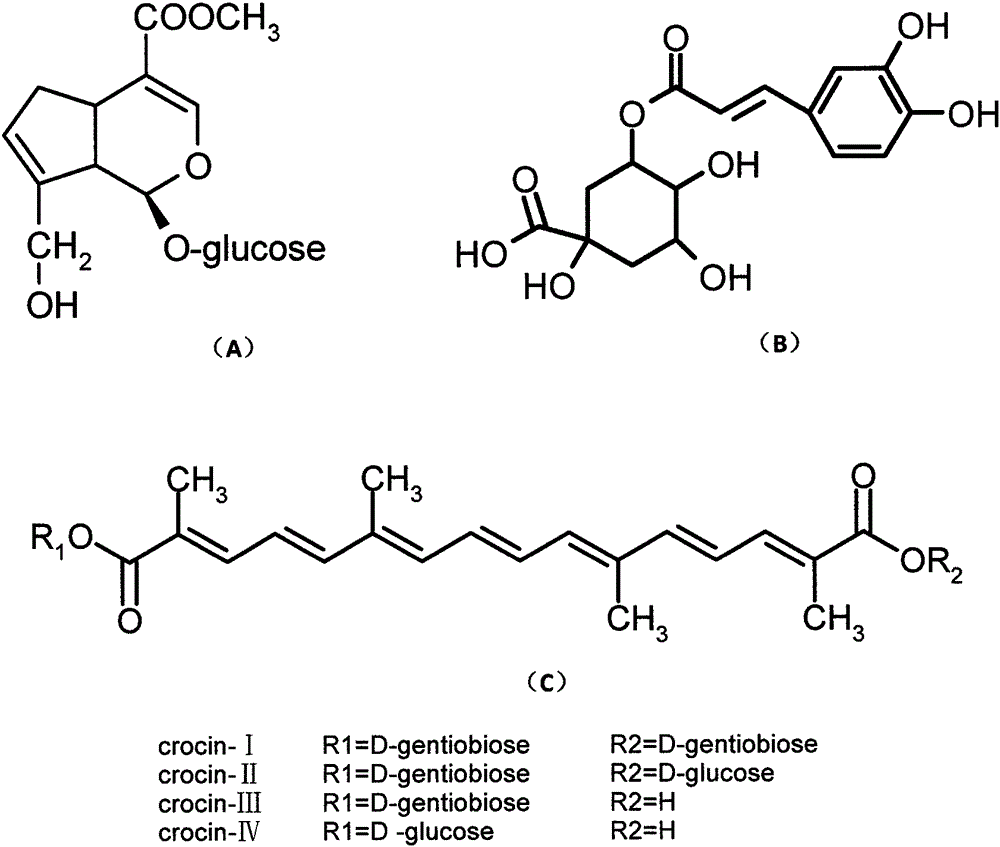

Simultaneous production of extractant and its extraction and separation method for multiple functional components of Gardenia jasminoides

An extraction agent, the technology of gardenia, is applied in the field of natural product extraction to achieve the effect of reducing production costs, reducing energy and solvent consumption, and avoiding structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

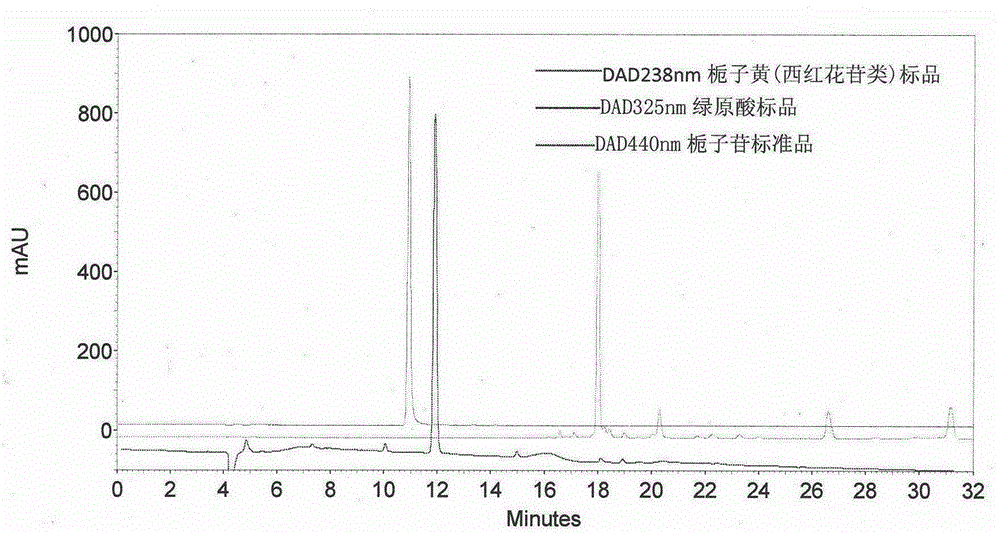

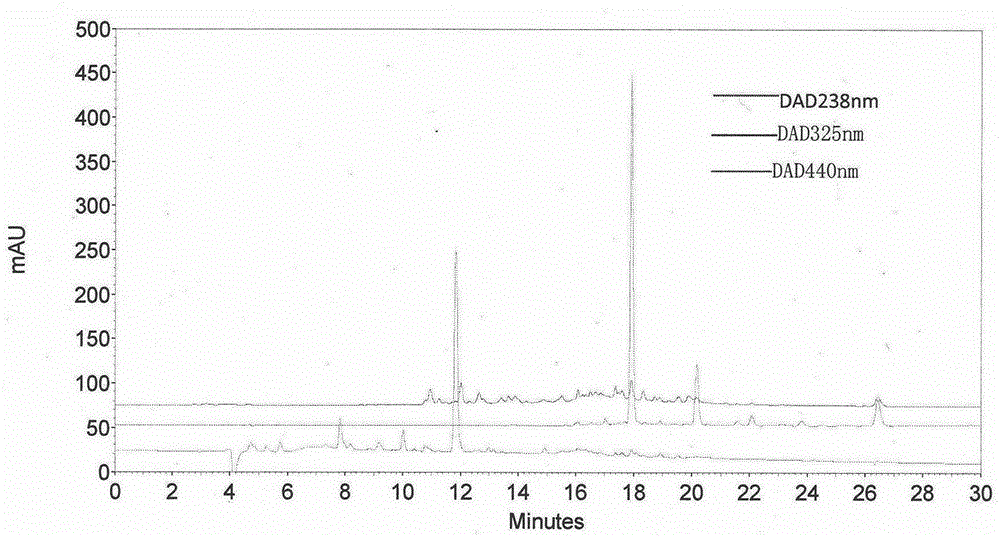

Method used

Image

Examples

Embodiment 1

[0065] Components and ratio of extractant (calculated by weight): metaphosphoric acid 0.03kg, Tween-800.03kg, tap water 50kg.

[0066] Take 4 kg of dried gardenia fruit, put it into the extraction tank, add 60 kg of extractant, cover and seal it to control the temperature at 50 ° C, stir intermittently for 5 minutes every hour, and after leaching for 6 hours, filter out the filtrate, and then add 20 kg of extractant to carry out For the second extraction in 4 hours, the two extracts were combined and 74kg was filtered out after coarse filtration by a centrifuge, and cooled to 25°C; The column removes the hydrophilic components, and this part of the eluate is fractionated and concentrated by microfiltration membrane, ultrafiltration, reverse osmosis membrane, and then vacuum-dried at low temperature or freeze-dried to obtain 0.5kg of gardenia pectin polysaccharide component; then use 25% ethanol Elution and elution with 70% ethanol, collect the eluent respectively, concentrate ...

Embodiment 2

[0069] Components and ratio of extractant (calculated by weight): sodium metaphosphate 0.5kg, sodium fatty acid methyl ester sulfonate 0.5kg, tap water 450kg.

[0070] Take 50kg of dried gardenia fruit and 500kg of extractant, put them into an extraction tank, control the temperature at 55°C, stir intermittently for 15 minutes per hour, after leaching for 6 hours, filter out the filtrate, and use 200kg of extractant for another 5 hours for the second extraction. For secondary extraction, the two extracts were combined and then filtered. After 650 kg of filtrate was cooled, it flowed through the HPD300 resin adsorption column for 4 hours. After the column was washed with 850 kg of deionized water successively, it was eluted with 25% ethanol and 80% ethanol respectively. The water eluate flows through the microfiltration membrane to filter and remove impurities, and then is fractionated and concentrated by ultrafiltration and reverse osmosis membrane to obtain the concentrated so...

Embodiment 3

[0073] Components and ratio of extractant (calculated by weight): metaphosphoric acid 0.2kg, sodium fatty acid methyl ester sulfonate 0.2kg, tap water 250kg.

[0074] Take 20kg of dried gardenia fruit and 250kg of extractant, put them into an extraction tank, control the temperature at 60°C, stir intermittently for 15 minutes per hour, after leaching for 5 hours, filter out the filtrate, and use 160kg of extractant for another 5 hours of extraction. For the second extraction, the two extracts were combined and then filtered. 400kg of the filtrate was cooled and passed through the HPD300 resin adsorption column. Filtration and reverse osmosis membrane fractional concentration to obtain a concentrated solution of gardenia polysaccharides, which was vacuum-dried at low temperature or freeze-dried to obtain 2.5 kg of gardenia pectin polysaccharide components; and then eluted with 20% ethanol and 65% ethanol respectively. The ethanol eluate was concentrated by vacuum rotary evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com