Carbon dioxide free radical based oxygen-containing liquid deoxygenation method

A technology of carbon dioxide and free radicals, applied in chemical instruments and methods, liquid degassing, separation methods, etc., can solve the problems of heavy metals and slow oxygen removal rate, expensive equipment, oxygen removal rate, expensive catalyst, etc., to achieve management and easy to operate, easy to obtain, and realize the effect of automatic management control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

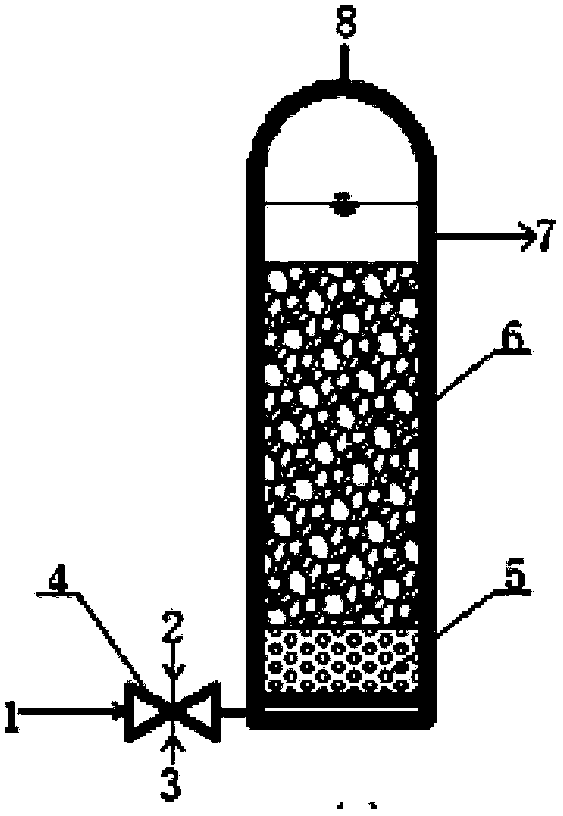

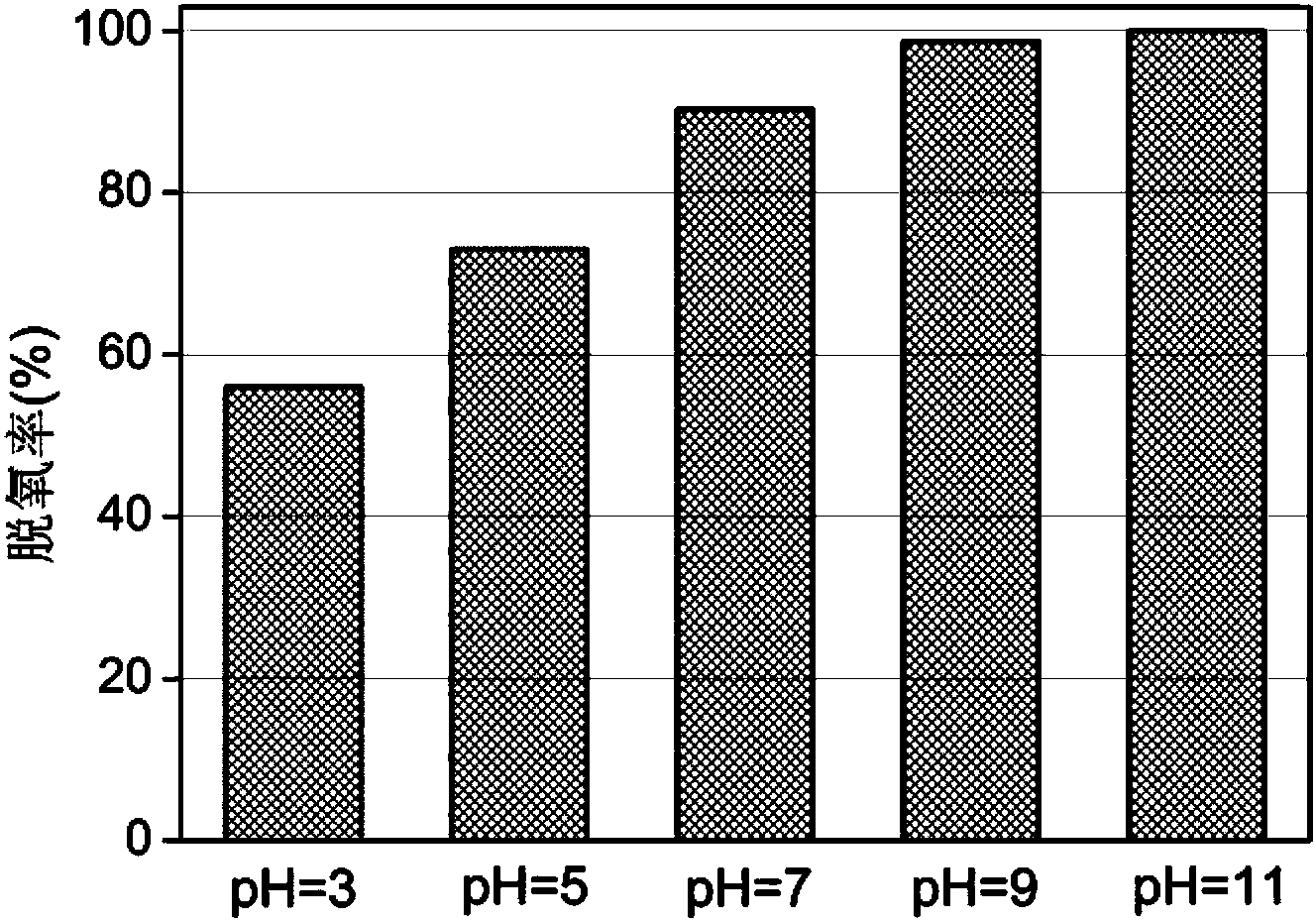

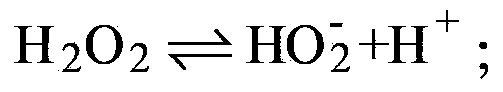

[0046] A method for removing oxygen from an oxygen-containing liquid based on carbon dioxide free radicals, the method for removing oxygen utilizes figure 1 The columnar reaction tower shown (inner diameter is 30cm), the 25mM H 2 o 2 and 0.5M sodium formate through the metering pump respectively from H 2 o 2 Feed port 2 and formate feed port 3 are added, H 2 o 2 and sodium formate are dosed at a dose of 100mL / min, and the two are first fully mixed with the raw water (the initial concentration of dissolved oxygen is 7.8mg / L, and the flow rate is 7.4L / min) from the raw water inlet 1 in the mixer 4 and then come into contact At the bottom of the tower, through the water distribution plate 5 and the activated carbon catalytic bed 6 (the filling height is 105cm, the corresponding empty bed contact time is 10min, and the material is alkaline coal broken activated carbon, purchased from Gongyi City Ultra Clean Water Material Factory, activated carbon The particle size is 20-40 m...

Embodiment 2

[0049] use the same figure 1 The columnar reaction tower shown (inner diameter is 30cm), the 25mM H 2 o 2 and 0.55M sodium formate from the H 2 o 2 Feed port 2 and formate feed port 3 are added, H 2 o 2 and sodium formate are dosed at a dose of 100mL / min, and the two are first fully mixed with the raw water (the initial concentration of dissolved oxygen is 7.8mg / L, and the flow rate is 7.4L / min) from the raw water inlet 1 in the mixer 4 and then come into contact The bottom of the tower, then through the water distribution plate 5 and the activated carbon catalytic bed 6 (filling height 105cm, the corresponding empty bed contact time is 10min, the material is neutral activated carbon, purchased from Gongyi City Ultra Clean Water Material Factory, the activated carbon particle size is 30 mesh) contact and react to deoxidize, adjust the oxygen-containing liquid, sodium formate and H 2 o 2 The pH of the mixture is 7, the CO produced 2 The gas is discharged from the exhaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com