Preparation method of tricobalt tetroxide monolithic catalyst for carbon monoxide purification

A monolithic catalyst, cobalt tetroxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low carbon monoxide purification efficiency, easy sintering and deactivation of precious metals, Catalyst waste and other issues, to achieve wide practicability, low cost, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

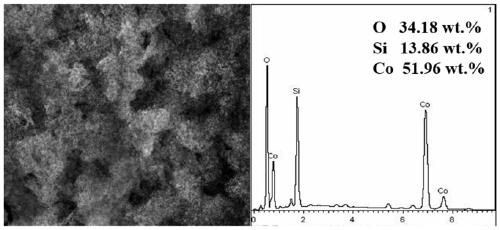

[0027] The preparation method of the tricobalt tetroxide monolithic catalyst for carbon monoxide purification of the present invention adopts iron-chromium-nickel metal honeycomb as the catalyst carrier, and the specific surface area of the iron-chromium-nickel metal honeycomb is 0.8-2m 2 / g, 400 mesh; the specific steps are as follows:

[0028] Step (1) Ultrasonic cleaning is performed on the iron-chromium-nickel metal honeycomb to remove impurities on the surface of the metal honeycomb, and then the ultrasonically cleaned metal honeycomb is placed in an oven to dry, and then treated by a combination of chemical erosion and heat treatment Dried metal honeycomb; the solution used in the ultrasonic cleaning is acetone, the ultrasonic frequency is 50 kHz, and the ultrasonic time is 3 h. The method of combining chemical attack and heat treatment is to immerse the dried metal honeycomb in 1mol / L sulfuric acid solution, heat it to 60°C for 30min, and then place the metal honeycom...

Embodiment 1

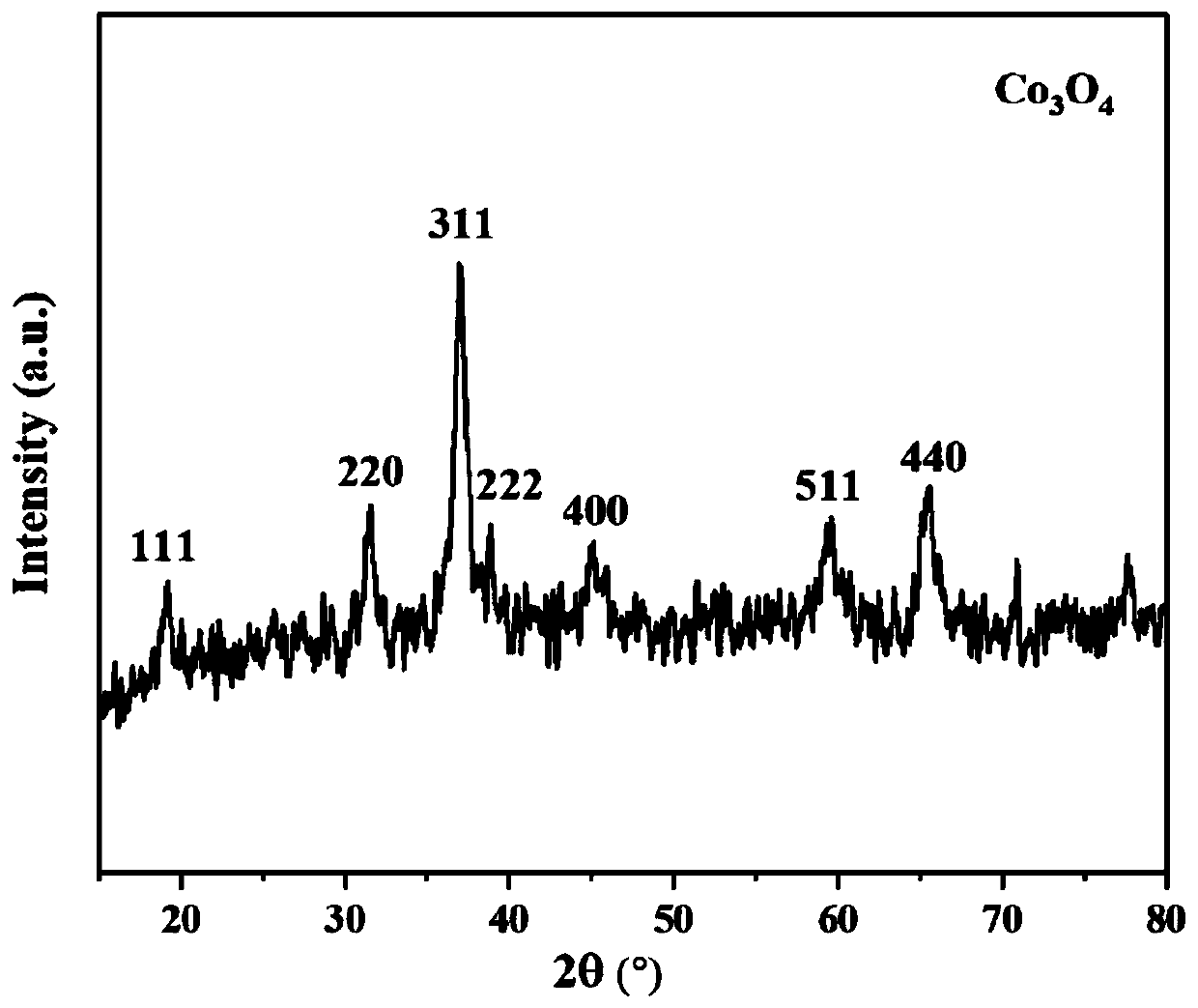

[0035] Example 1: Preparation of Cobalt Tetroxide Monolithic Catalyst for Carbon Monoxide Purification

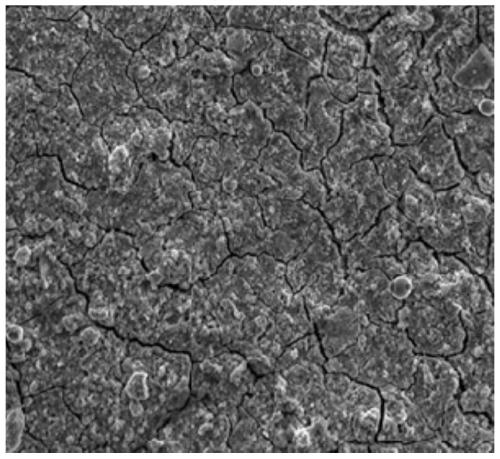

[0036]Dissolve 4.98g of cobalt acetate in 60mL of ethylene glycol solution, heat to 160°C and maintain for one hour; slowly add 200ml of 0.2M sodium carbonate solution to the above solution, and age for 1h; filter the obtained solution, and repeat Cleaning with deionized water and ethanol solution; drying the filtered solid in an oven; then calcining in a muffle furnace, and the final black powdery substance is the nano-catalyst of cobalt trioxide. Grind 3g of cobalt tetroxide nanocatalyst into 150 mesh or more with a mortar, and dry the obtained powder at 50°C for 4h; then add 3g of cobalt tetroxide catalyst powder and 9g of silica sol into 100mL of deionized water, stir for 4h to obtain a suspension solution; put a 400-mesh metal honeycomb carrier with a height of 50mm and a diameter of 17mm in an acetone solution, ultrasonicate at 50kHz for 3h, and dry at 60°C for 2h; im...

Embodiment 2

[0038] Embodiment 2: Oxidation of carbon monoxide with tricobalt tetroxide monolithic catalyst for carbon monoxide purification

[0039] The catalytic activity of cobalt trioxide monolithic catalysts for carbon monoxide purification was evaluated by the efficiency of the digestion of carbon monoxide. Carbon monoxide oxidation is carried out in a fixed-bed catalytic reaction evaluation device. A 400-mesh monolithic catalyst with a height of 50mm and a diameter of 17mm is fixed in a quartz tube, and a mixed gas containing 0.5% carbon monoxide, 15% oxygen and 84.5% nitrogen is passed into the reactor. In the process, the gas velocity is adjusted to achieve different space velocities, and the gas purified by the tricobalt tetroxide monolithic catalyst is detected by a chromatograph for the concentration of carbon monoxide.

[0040] The evaluation results of the catalytic performance of the cobalt tetraoxide monolithic catalyst are attached Figure 4 shown. It can be seen from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com