Photocatalyst for selective oxidation of toluene and toluene derivatives

A photocatalyst, gr-cds-tio2 technology, applied in the field of catalyst preparation and sustainable development of the environment and energy, to achieve the effect of simple production process, high photocatalytic activity and selectivity, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

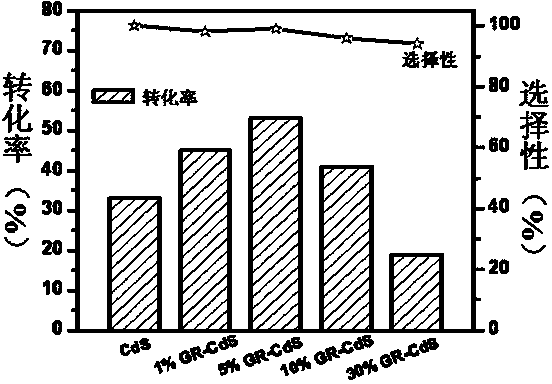

Embodiment 1

[0028] 200 mL of 6.0 mM Na 2 S solution was slowly added dropwise to 200 mL 5.0 mM Cd(Ac) 2 solution, continued to stir for 36 h, then filtered, washed, and dried to obtain a CdS sample. The sample was dispersed in deionized water, placed in a reactor at 120 °C for 12 h, accounting for 80% of the reactor, then cooled, filtered, washed, and dried to obtain a CdS photocatalyst. Mix 8 mg of CdS catalyst, 1.5 mL of BTF pre-passed through oxygen, and 0.1 mmol of toluene or its derivatives, and place it under visible light (>420 nm) for 10 h. The conversion rate of toluene is 33%, and the conversion rate of p-chlorotoluene is 27%, the conversion rate of p-methoxytoluene is 36%, the conversion rate of p-nitrotoluene is 29%, the conversion rate of p-fluorotoluene is 30%, the conversion rate of p-xylene is 39%, the selection of corresponding aldehyde Sex is 100%.

Embodiment 2

[0030] 200 mL of 6.0 mM Na 2 S solution was slowly added dropwise to 200 mL 5.0 mM Cd(Ac) 2 solution, continue to stir for 36 h, then filter, wash, and dry to obtain CdS solid; disperse a certain amount of GO in water, add a certain amount of CdS solid (m / m 0.01-0.3:1) in proportion, and stir together for 24 h. Then, the self-assembled sample was obtained by rotary evaporation in a water bath at 50°C; the self-assembled sample was dispersed in deionized water, placed in a reactor at 120°C for 12 h, accounting for 80% of the reactor, then cooled, filtered, washed, and dried Obtain GR-CdS photocatalyst. Mix 8 mg of 5% GR-CdS catalyst, 1.5 mL of BTF pre-passed through oxygen, and 0.1 mmol of toluene or its derivatives, and place it under visible light (>420 nm) for 10 h. The conversion rate of toluene is 53%, and p-chlorotoluene The conversion rate of p-methoxytoluene is 52%, the conversion rate of p-methoxytoluene is 57%, the conversion rate of p-nitrotoluene is 51%, the conve...

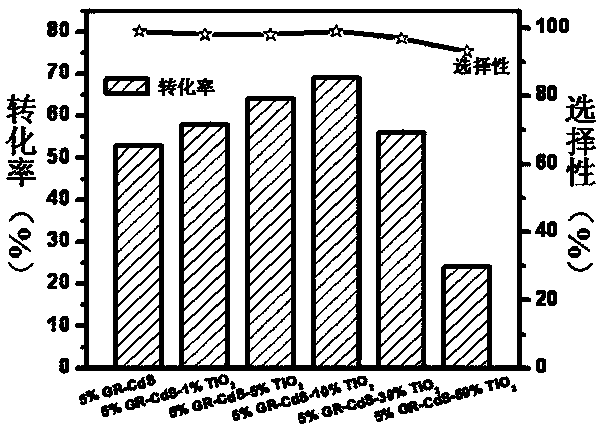

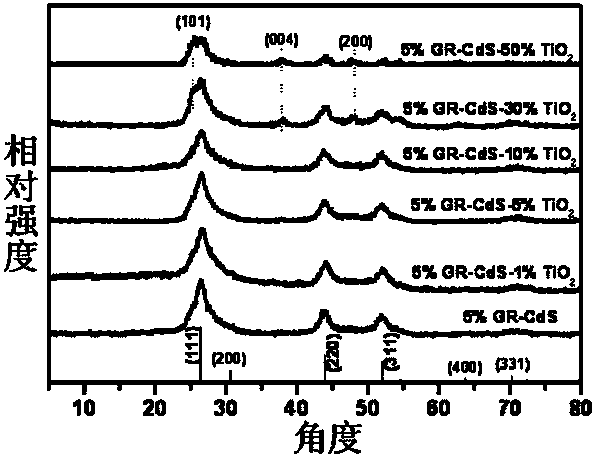

Embodiment 3

[0032] 200 mL of 6.0 mM Na 2 S solution was slowly added dropwise to 200 mL 5.0 mM Cd(Ac) 2 solution, continue to stir for 36 h, then filter, wash, and dry to obtain CdS solid; disperse a certain amount of GO in water; disperse a certain amount of liquid n-butyl titanate in absolute ethanol, seal, and poke a few a small hole, stirred for 48 h to obtain TiO 2 Colloid; CdS solid, TiO 2Colloid and GO aqueous solution were mixed according to a certain ratio (m / m 45-94:1-50:5), stirred together for 24 hours, and then 50°C water bath was rotated to dryness to obtain self-assembled samples; the self-assembled samples were dispersed in deionized water , placed in a reactor at 120°C for 12 h, accounting for 80% of the reactor, then cooled, filtered, washed, and dried to obtain GR-CdS-TiO 2 catalyst of light. 8 mg 5%GR-CdS-10%TiO 2 Catalyst, 1.5 mL of BTF pre-passed through oxygen and 0.1 mmol of toluene or its derivatives were mixed uniformly, placed under visible light (>420 nm) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com