Formula and manufacturing method for pholiota nameko cultivation material

The technology of a slippery mushroom cultivation material and a production method, which is applied in the field of slippery mushroom cultivation material compatibility, can solve problems such as air, water source and ecological environment pollution, and a small processing ratio, so as to broaden cultivation raw material channels, increase yield, and improve air permeability The effect of sex and water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

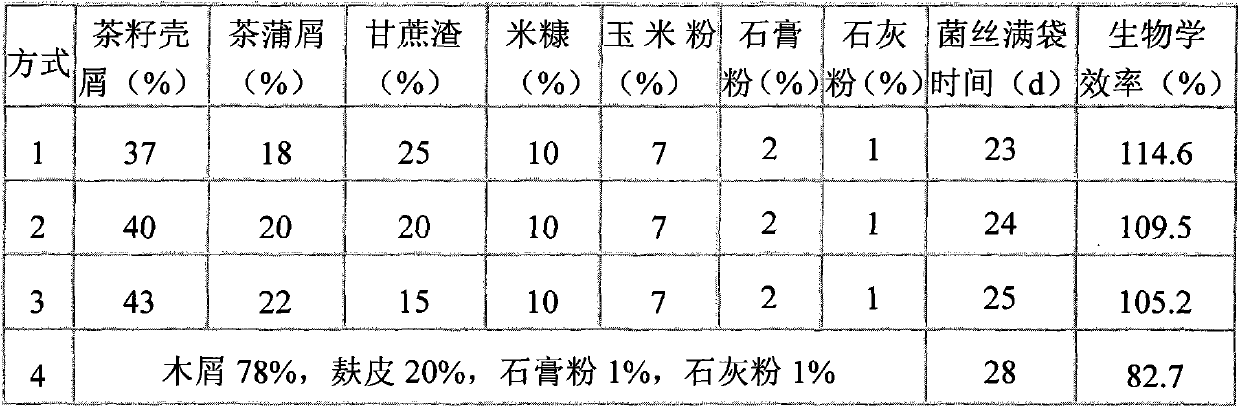

[0026] Method 1: In this embodiment, the cultivation material of Pleurotus ostreatus includes the following components and mass ratio: 37% of tea seed shell chips, 18% of tea cattail leaves, 25% of bagasse, 10% of rice bran, 7% of corn flour, and 2% of gypsum powder. %, lime powder 1%, are all the quality of dry matter, and the sum of proportioning is 100%.

[0027] Production Method:

[0028] ①Sunning material: Expose the raw material for 1 day before mixing the material, and use ultraviolet rays to kill some bacteria in the raw material;

[0029] ②Pre-wetting: First, mix the tea seed husk and tea cattail in a dry state evenly, and then pre-wet with 1% lime aqueous solution (fully soaked);

[0030] ③ Stacking and fermentation: Pile the wet material into a trapezoidal pile with a height of 1.2m, a width of 2m, and a length of 5m. At the bottom of the pile, the air hole density is 1 / m 3 , and finally covered with thatch to let it ferment naturally;

[0031] ④ Turning: When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com