Method for synthesizing 4-chloro-pyridine

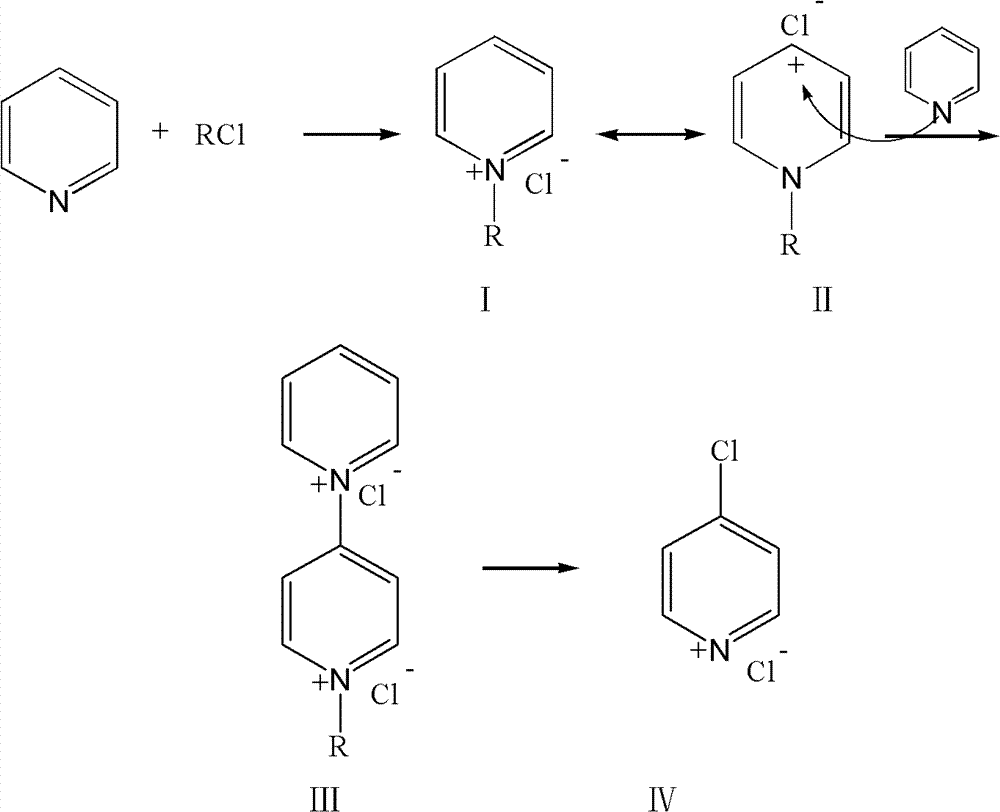

A synthetic method, the technology of chloropyridine, which is applied in the field of synthesis of pharmaceutical and pesticide intermediates, can solve the problems of few manufacturers in the research of 4-chloropyridine synthesis, affect the continuous production of industrial reactions, and blockage of reactors, etc., and achieve the solution of pyridine coking , easy to industrialized production, the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Starting material: pyridine; organic solvent: ethyl acetate; chlorination reagent: thionyl chloride

[0032] Add 200g of anhydrous pyridine and 100-200mL of ethyl acetate in sequence in a 1000mL reaction flask, protect with nitrogen, cool in a cold water bath, slowly add 200g of thionyl chloride dropwise under stirring, and the temperature does not exceed 40°C. After the addition, the temperature was raised and kept at 70-75° C. for 5 hours. During this period, the color of the reaction mixture gradually became darker, and finally turned into a black oily substance. Cool down and let it stand, add 500ml ethanol to the reaction solution, heat it at 50-60°C and stir for 1 hour, cool down to about 10°C, filter, it is easier to filter with suction, the filtrate is dark, the solid is dark brown, soak in absolute ethanol Wash and dry to obtain 266.8 grams of tan solid powder, with a yield of about 70.2%. Its purity was 95.6% as determined by HPLC. The product was identifie...

Embodiment 2

[0034] Starting material: pyridine; Organic solvent: dichloromethane; Chlorinating reagent: phosphorus oxychloride

[0035] Add 200g of anhydrous pyridine and 150mL of dichloromethane to a 1000mL reaction flask in sequence, cool in a cold water bath, slowly add 160g of phosphorus oxychloride dropwise under stirring, and the temperature does not exceed 50°C. After the addition, the temperature was raised and kept at 70-75° C. for 5 hours. During this time, the color of the reaction mixture gradually became darker. Cool down and stand still, add 500ml ethanol to the residue in the lower layer, heat at 50-60°C and stir for 1 hour, cool down to about 10°C, filter, easy to filter with suction, the filtrate is dark, the solid is dark brown, use absolute ethanol Soak, wash, and dry to obtain 152 grams of tan solid powder, with a yield of about 52.4%. Its purity was 93.9% as determined by HPLC. The product was identified as 4-chloropyridine hydrochloride by NMR identification. The...

Embodiment 3

[0037] Starting material: pyridine; organic solvent: chlorobenzene; chlorination reagent: phosphorus pentachloride

[0038] Add 100g of anhydrous pyridine and 100mL of chlorobenzene in sequence in a 500mL reaction bottle, protect with nitrogen, cool in a cold water bath, slowly add 100g of phosphorus pentachloride dropwise under stirring, and the temperature does not exceed 30°C. After the addition, the temperature was raised and kept at 70-75° C. for 5 hours. During this time, the color of the reaction mixture gradually became darker. Cool down and let it stand, add 300ml n-butanol to the residue in the lower layer, heat it at 50-60°C and stir for 1 hour, cool down to about 10°C, filter, it is easier to filter with suction, the filtrate is dark, the solid is dark brown, dry it 116.2 g of tan solid powder was obtained, with a yield of about 61.3%. Its purity was 92.7% as determined by HPLC. The product was identified as 4-chloropyridine hydrochloride by NMR identification. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com