Polymerization device for preparing spherical water-absorbent resin and method of using same to prepare spherical water-absorbent resin

A technology of water-absorbent resin and polymerization device, which is applied in the field of preparing spherical water-absorbent resin, which can solve the problems of unfavorable industrial production, increased resin particle size factors, and increased synthesis steps, etc., and achieves the effects of simple equipment, shortened reaction time, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

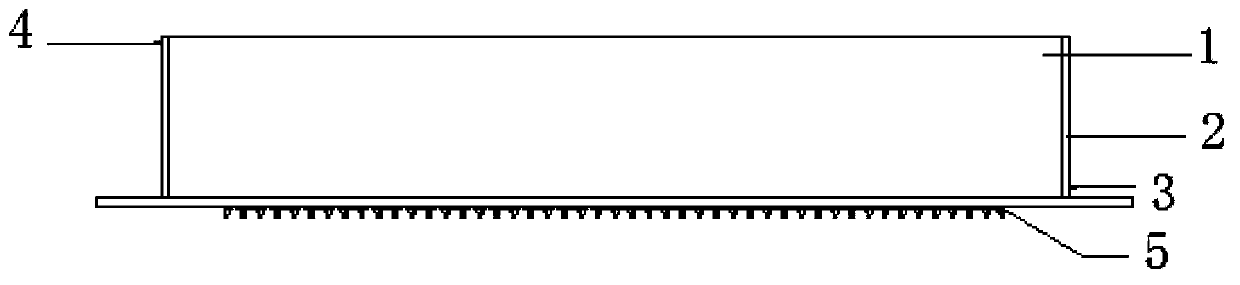

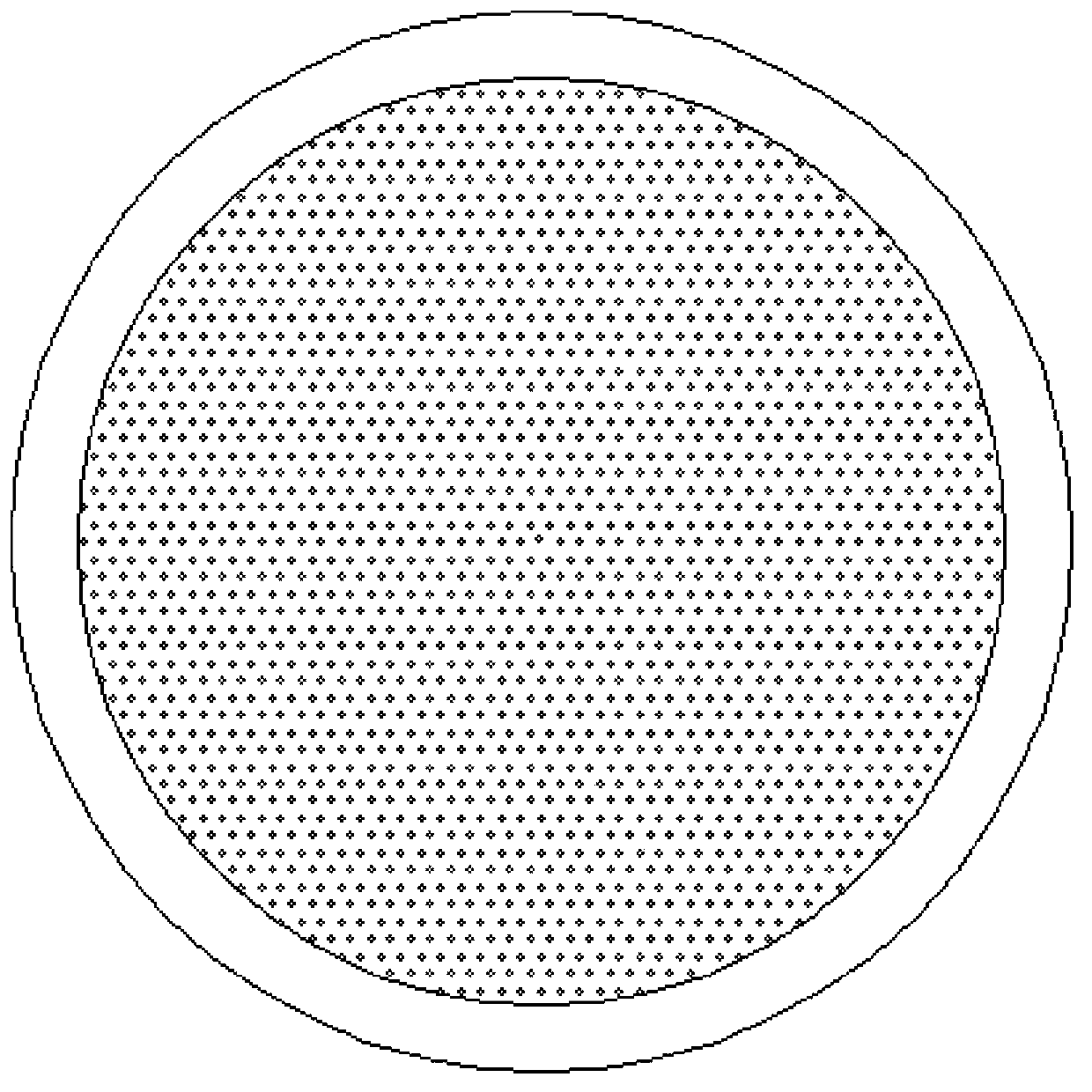

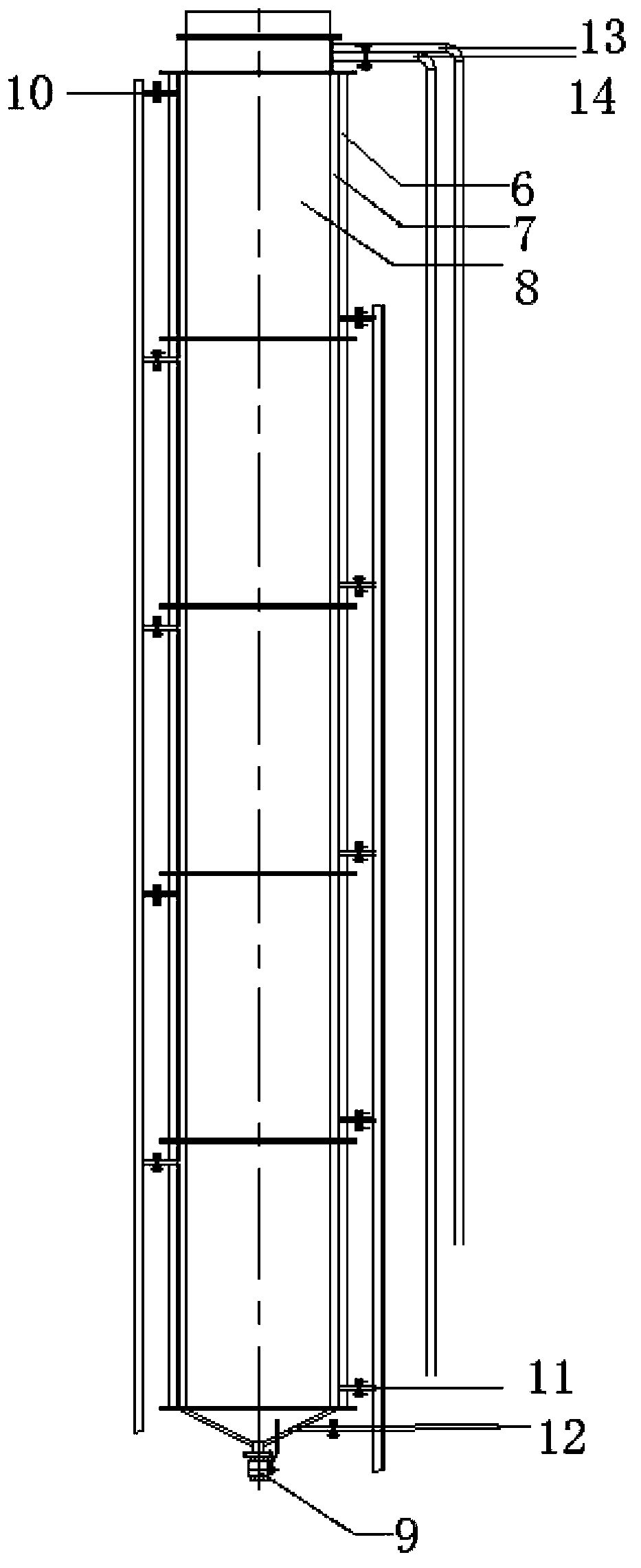

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the spherical water-absorbent resin in this embodiment comprises the following steps:

[0041] Step 1, the preparation of aqueous phase solution:

[0042] Add 13.2g of NaOH to 29.2g of water, stir to make it completely dissolve and cool down. After the NaOH solution drops to room temperature, add this solution to 22.2g of methacrylic acid monomer, and stir and cool it. When the temperature is below 25°C, add 10.3g of acrylamide, stir to dissolve, and adjust the pH to 6.5-7.2;

[0043]Then add 0.1~0.2g of cross-linking agent N,N-methylenebisacrylamide, stir rapidly until it is completely dissolved, then add 0.08~0.1g of azobispropaneamine hydrochloride under the condition of rapid stirring, keep The temperature of the system is around 10°C to obtain an aqueous phase solution; the density of the aqueous phase solution is 1.02g / cm 3 .

[0044] Step 2, preparing spherical water-absorbing resin:

[0045] Put the methyl silicone oil (viscosity 20...

Embodiment 2

[0048] The preparation method of the spherical water-absorbent resin in this embodiment comprises the following steps:

[0049] Step 1, the preparation of aqueous phase solution;

[0050] Add 19.3g of KOH to 23.2g of water, stir to make it completely dissolve and cool down. After the KOH solution drops to room temperature, add this solution to 29.2g of butyl methacrylate monomer, and stir and cool. After cooling to below 25°C, add 15.5g of acrylamide, stir to dissolve and then adjust the pH within the range of 6.5 to 7.2;

[0051] Then add 0.1~0.2g of cross-linking agent N,N-methylenebisacrylamide, stir rapidly until it is completely dissolved, then add 0.08~0.1g of 2,2-azobis(2-amidine Azoline propane) hydrochloride, keep the system temperature at about 10°C; the density of the aqueous phase solution is 1.0g / cm 3 ;

[0052] Step 2, preparing spherical water-absorbing resin:

[0053] Put the methyl silicone oil (viscosity 1500cp) solution in the polymerization reaction col...

Embodiment 3

[0056] The preparation method of the spherical water-absorbent resin in this embodiment comprises the following steps:

[0057] Step 1, the preparation of aqueous phase solution;

[0058] Add 21.5g of NaOH to 26.2g of water, stir to make it completely dissolve and cool down. After the NaOH solution drops to room temperature, add this solution to 30.2g of methacrylic acid monomer, and stir and cool it. When the temperature is below 25°C, add 5.6g of acrylamide to adjust the pH within the range of 6.5 to 7.2;

[0059] Then add 0.05-0.1 g of cross-linking agent divinylbenzene, stir rapidly until it is completely dissolved, then add 0.08-0.1 g of potassium persulfate under the condition of rapid stirring, and keep the temperature of the system at about 10°C; the aqueous phase solution The density is 1.05g / cm 3 ;

[0060] Step 2, preparing spherical water-absorbing resin:

[0061] Put the methyl silicone oil (viscosity 1500cp) solution in the polymerization reaction column, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap