High-performance high-density polyethylene (HDPE) pipe fitting

A high-performance, pipe technology, used in rigid pipes, hoses, pipes, etc., can solve the problems of untreated clean, insufficient weld strength, insufficient butt area requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A high-performance HDPE pipe, the mass percentage of its raw material components is:

[0078] Functional masterbatch 0.1%

[0079] HDPE base material 99.9%

[0080] A high-performance HDPE pipe preparation method, characterized in that raw materials→mixing→vacuum feeding→raw material drying→inner layer extruder→outer layer extruder→sizing sleeve→spraying vacuum calibrating box→spraying Cooling water tank → inkjet printer → crawler tractor → finished product testing and packaging HDPE pipe specifications;

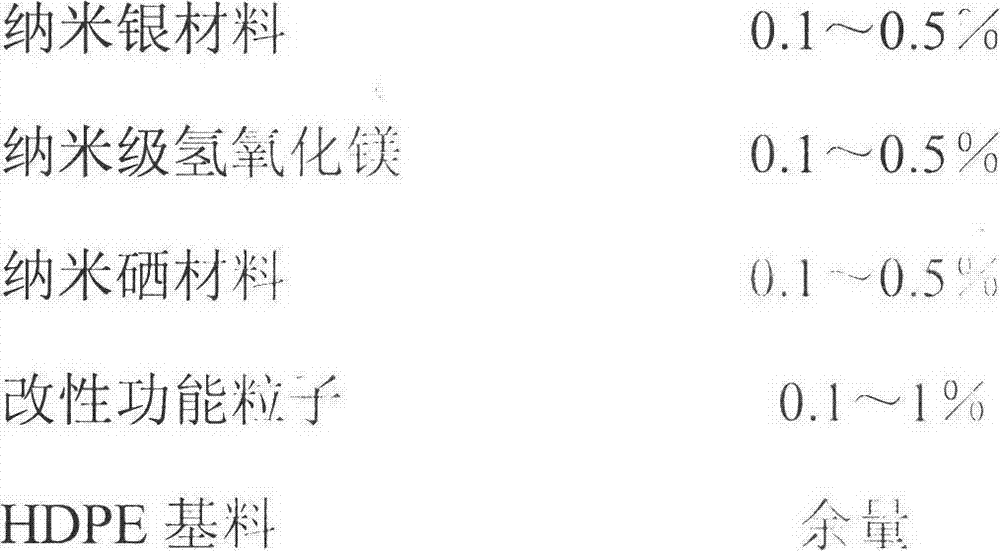

[0081] A functional masterbatch, the mass percentage of its raw material components is:

[0082]

[0083] The invention relates to a preparation method of a functional master batch, which comprises mixing and granulating raw materials to obtain the functional master batch.

Embodiment 2~5

[0085] Table 1 is the mass percentage of raw material components of high-performance HDPE pipes

[0086] Component Example 2 Example 3 Example 4 Example 5 Functional Masterbatch 0.3% 0.5% 0.7% 1% HDPE base material 99.7% 99.5% 99.3% 99%

[0087] Table 2 is the mass percentage of raw material components of functional masterbatch

[0088] Component Example 2 Example 3 Example 4 Example 5 nano silver material 0.2% 0.3% 0.4 0.5 Nano Magnesium Hydroxide 0.2% 0.3% 0,4 0.5 Nano-selenium material 0.2% 0.3% 0.4 0.5 Modified functional particles 0.3% 0.5% 0.7% 1% HDPE base material 99.1% 98.6% 98.1% 97.5%

[0089] All preparation methods of embodiment 2~5 are the same as embodiment 1.

Embodiment 6

[0091] A high-performance HDPE double-wall corrugated pipe, the mass percentage of its raw material components is:

[0092] Functional masterbatch 1%

[0093] HDPE base material 99%

[0094] A method for preparing a high-performance HDPE double-wall corrugated pipe, characterized in that the functional masterbatch and the HDPE base material are mixed, and the inner layer extruder and the outer layer extruder are respectively used for co-extrusion and compounding. Forming, cooling and setting, traction cutting and flaring to obtain high-performance HDPE double-wall corrugated pipes. The specific molding process conditions are: barrel temperature 170-190°C, head temperature 190-210°C, main engine speed 628r / min, auxiliary machine speed 520r / min; air pressure inside the flare 14kPa, module vacuum 0.050-0.075MPa; air pressure outside the flare 10kPa, jacket water pressure 0.25MPa, head vacuum 0.04~0.05kPa.

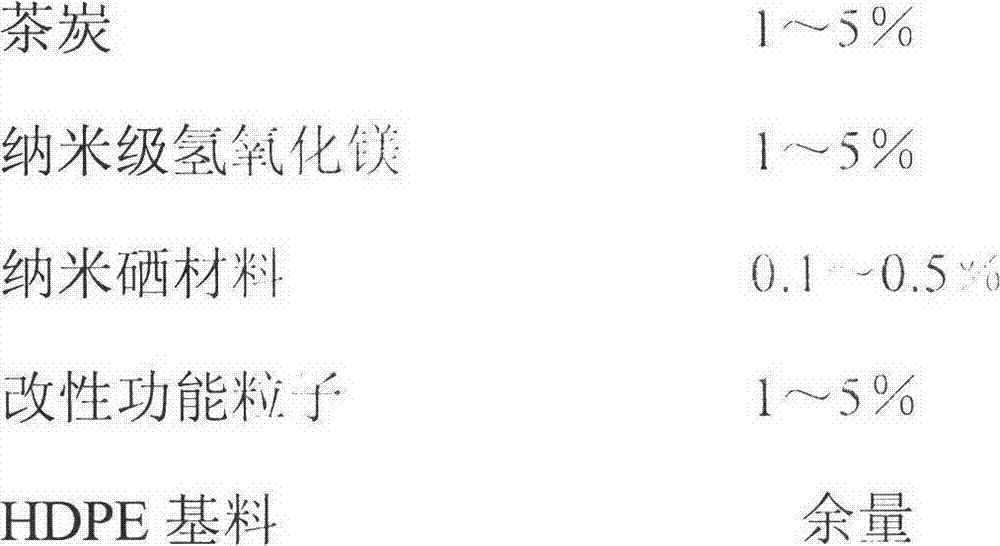

[0095] A functional masterbatch, the mass percentage of its raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com