Dual-photoresist and processing method thereof

A processing method and photoresist technology, applied in the direction of microlithography exposure equipment, optics, optomechanical equipment, etc., can solve the problems of low etching selection and poor fidelity of pattern transfer, and achieve pattern accuracy, light reduction, etc. Effect of small loss of fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

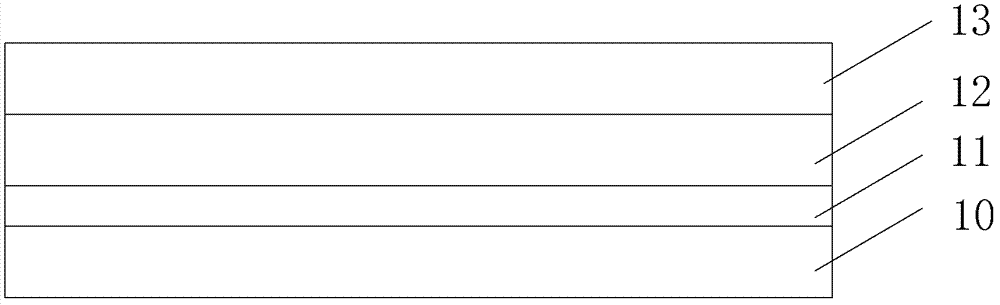

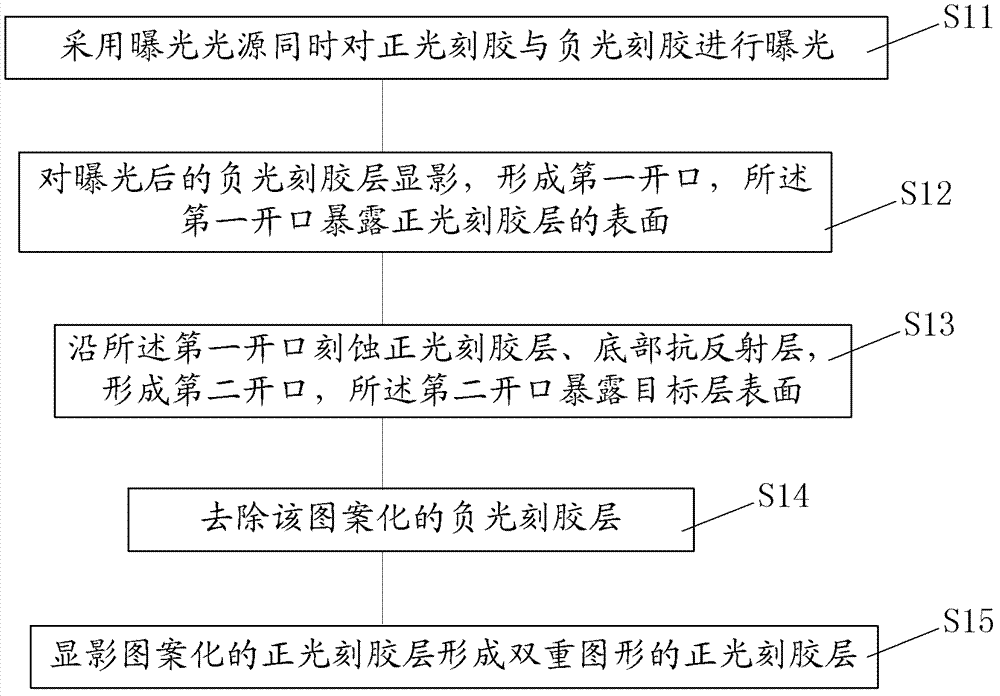

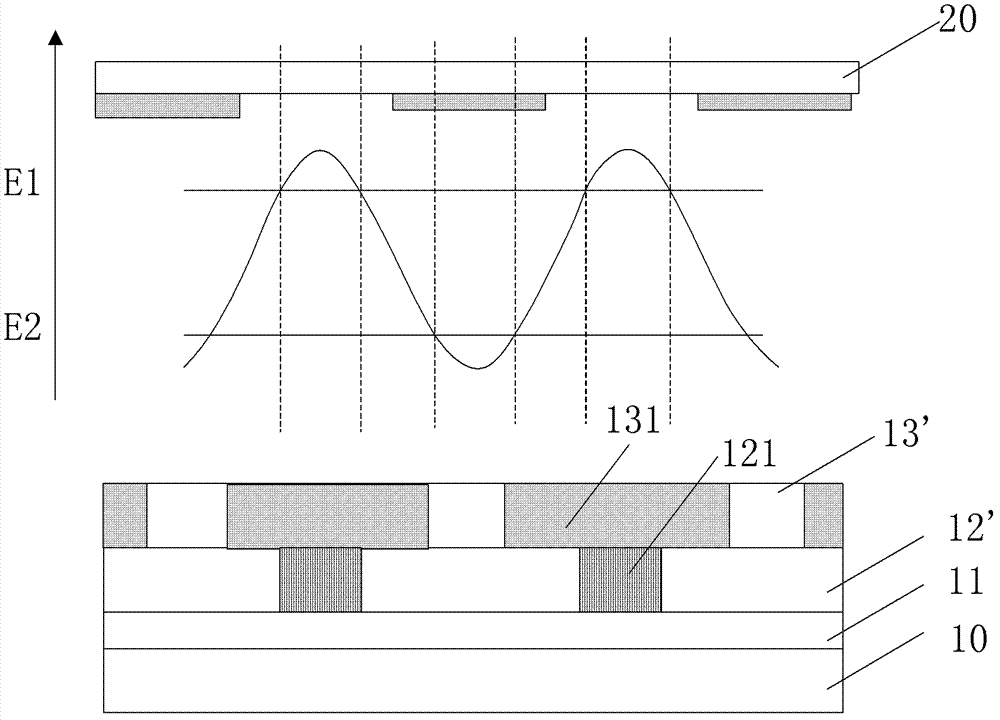

[0037] refer tofigure 1 As shown, the double photoresist provided in the first embodiment is formed on the target layer 10 , which are bottom antireflection layer (BARC) 11 , positive photoresist layer 12 and negative photoresist layer 13 in sequence from bottom to top. The bottom anti-reflection layer 11 is used to increase the intensity of bottom light in the exposure process, and the material can be selected from existing BARC materials, and can be an organic anti-reflection coating or an inorganic anti-reflection coating.

[0038] The inorganic antireflection coating is made of, for example, titanium (titanium), titanium oxide (titanium oxide), titanium nitride (titanium nitride), chromium oxide (chromium oxide), carbon (carbon), amorphous silicon (amorphous silicon), nitrogen Silicon nitride (silicon nitride), silicon nitride oxide (silicon nitride oxide), silicon carbon oxide (silicon carbon oxide) and other materials; the organic anti-reflection coating is made of, for e...

Embodiment 2

[0061] The structure and processing method of the double photoresist provided in the second embodiment and the first embodiment are roughly the same, the only difference is that the double photoresist on the target layer 10 is sequentially from bottom to top: bottom anti-reflection layer (BARC) 11. Negative photoresist layer and silicon-containing water-soluble positive photoresist layer. Wherein, the material selection of each layer of the negative photoresist layer and the silicon-containing water-soluble positive photoresist layer is the same as that of the first embodiment. The bottom anti-reflection layer 11 is an optional layer, which is used to increase the intensity of bottom light in the exposure process, and the material can be selected from existing BARC materials.

[0062] Aiming at the differences between the second embodiment and the first embodiment, the method for processing the double photoresist in the second embodiment will be briefly introduced below. Firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com