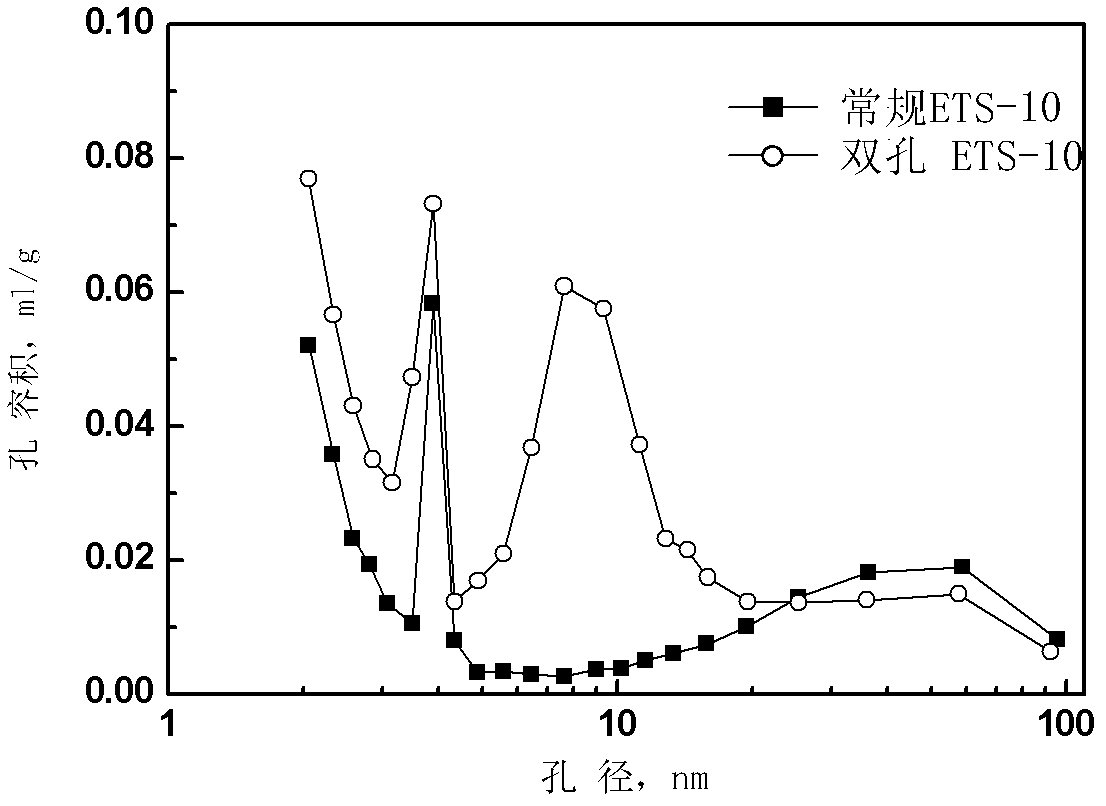

Dual-pore composite alumina material

A technology of composite alumina and small-pore alumina, which is applied in the direction of catalyst carriers, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of dispersion and peptization, reduce the yield of liquid products, etc., and achieve good thermal stability , Appropriate pore size distribution, conducive to the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In the preparation process of the double-hole composite alumina material in the present invention, extrusion aids can be used for extruding, and the commonly used extrusion aids can be kale powder, citric acid, oxalic acid, cellulose, starch, and polymer surfactants. One or more of them, preferably scallop powder, citric acid and polymer surfactant.

[0022] The shape of the double-hole composite alumina material of the present invention can be flake, spherical, cylindrical strip or special-shaped strip (clover, four-leaf clover), preferably cylindrical strip and special-shaped strip (clover, four-leaf clover). The diameter of the catalyst can be a thin strip of 0.8 mm to 2.0 mm or a thick strip >2.5 mm, preferably a thin strip of 1.0 mm to 1.8 mm.

Embodiment 1

[0025] Get 10g of small-pore pseudo-boehmite, 90g of large-pore pseudo-boehmite, add 5g of fenugreek powder, mix well, add dropwise a mixture of 7.5g of nitric acid (68wt.%), 5g of citric acid and 100g of deionized water. The solution was kneaded, extruded into a clover shape of 1.5mm, dried at 120°C for 2 hours, and then calcined at 550°C for 4 hours to make a double-porous composite alumina material A.

Embodiment 2

[0027] Take 20g of small-pore pseudo-boehmite, add 5g of scallop powder to 80g of large pores, mix well, add dropwise a mixed solution consisting of 7.5g of nitric acid (68wt.%), 5g of citric acid and 100g of deionized water and knead, extrude Form a clover shape of 1.5 mm, dry at 120°C for 4 hours, and then bake at 550°C for 4 hours to make a double-porous composite alumina material B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com