A kind of environment-friendly water-based zno printing paste and preparation method thereof

A water-based, environmentally friendly technology, applied in the direction of varistor cores and varistors, etc., can solve the problems of serious physical injury to production line workers, odor of printing paste, and equipment is not easy to clean, so as not to damage physical health and raw materials. The effect of low carbon, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

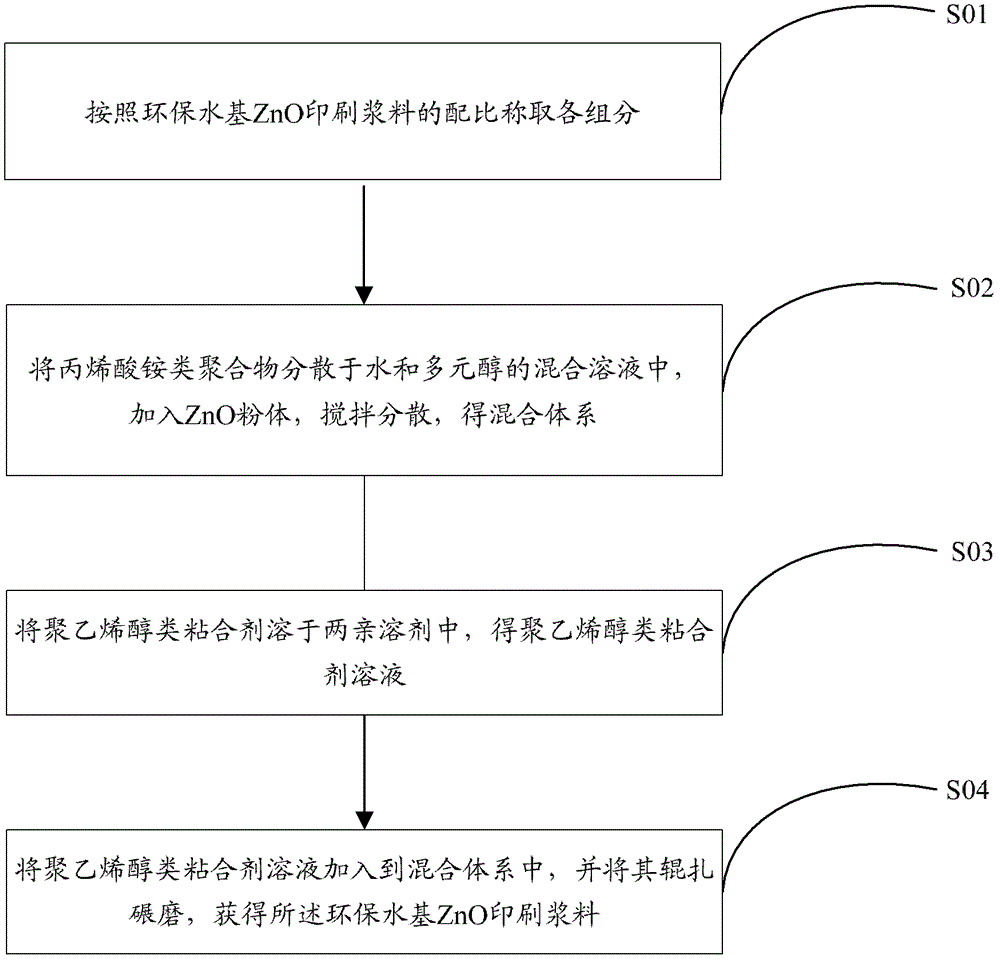

[0031] see figure 1 , the embodiment of the present invention also provides a method for preparing an environmentally friendly water-based ZnO printing paste, comprising the following steps:

[0032] S01: Weigh each component according to the proportion of the above-mentioned environmentally friendly water-based ZnO printing paste;

[0033] S02: Dissolve the ammonium acrylate polymer in the mixed solution of water and polyol, add ZnO powder, stir and disperse to obtain a mixed system;

[0034] S03: dispersing the polyvinyl alcohol adhesive in an amphiphilic solvent to obtain a polyvinyl alcohol adhesive solution;

[0035] S04: Add the polyvinyl alcohol binder solution prepared in step S03 to the mixing system prepared in step S02, and roll and grind it to obtain the environmentally friendly water-based ZnO printing paste.

[0036] In step S01, the ratio of each component is selected and accurately calculated. The preferred contents and types of each component of the environ...

Embodiment 1

[0043]Add 0.6 g of ammonium polyacrylate dispersant to 100 g of water and ethylene glycol solution with a weight ratio of 1:0.7, and then add 280 g of ZnO powder, stir and disperse to obtain a mixed solution.

[0044] Weigh 5g of polyvinyl alcohol adhesive GH-22 polyvinyl alcohol and disperse it in 15g of ethylene glycol butyl ether, then add it to the above mixed solution, stir, roll and grind on a roller mill to obtain the environmentally friendly water-based ZnO printing paste.

Embodiment 2

[0046] Add 0.55 g of ammonium polyacrylate dispersant to 100 g of water and propylene glycol solution with a weight ratio of 1:0.8, and then add 320 g of ZnO powder, stir and disperse to obtain a mixed solution.

[0047] Weigh 5.9g polyvinyl alcohol adhesive GH-22 type polyvinyl alcohol and disperse it in ethylene glycol butyl ether, then add it to the above mixed solution, stir, roll and grind on a roller mill to obtain the environmentally friendly water ZnO-based printing paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com