Three-dimensional packaging method having heat radiation function

A three-dimensional packaging and functional technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of shortening the working life of the device, affecting the working performance of the device, and increasing the temperature of the packaged device, so as to achieve the controllability of heat dissipation , heat dissipation is targeted, and the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the method and advantages of the present invention clearer and easier to understand, a three-dimensional packaging method with heat dissipation function provided by the present invention will be described in detail below with reference to the accompanying drawings.

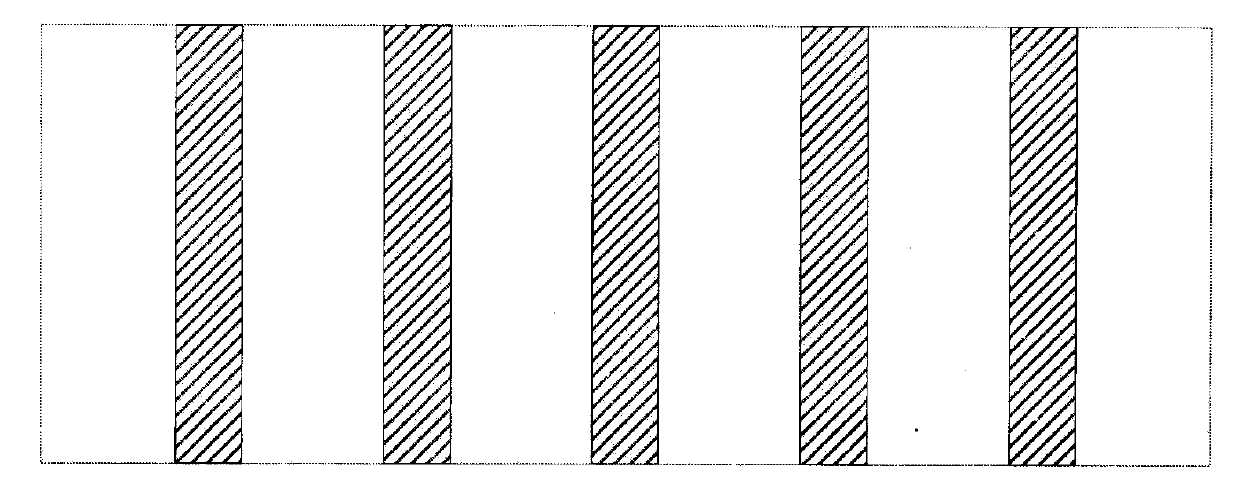

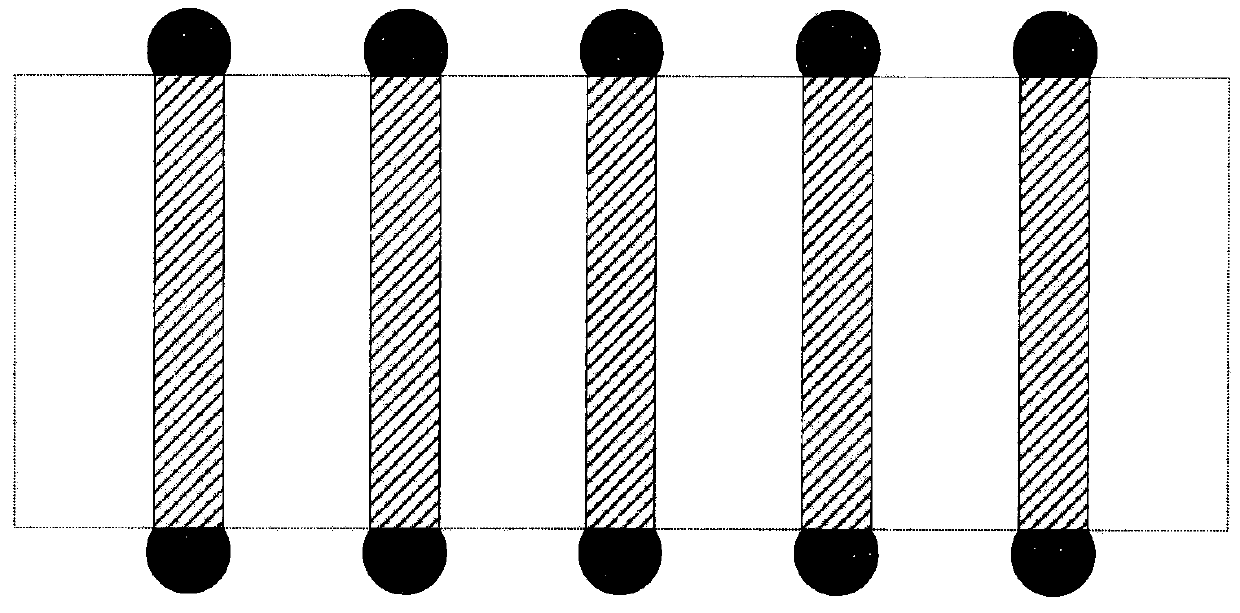

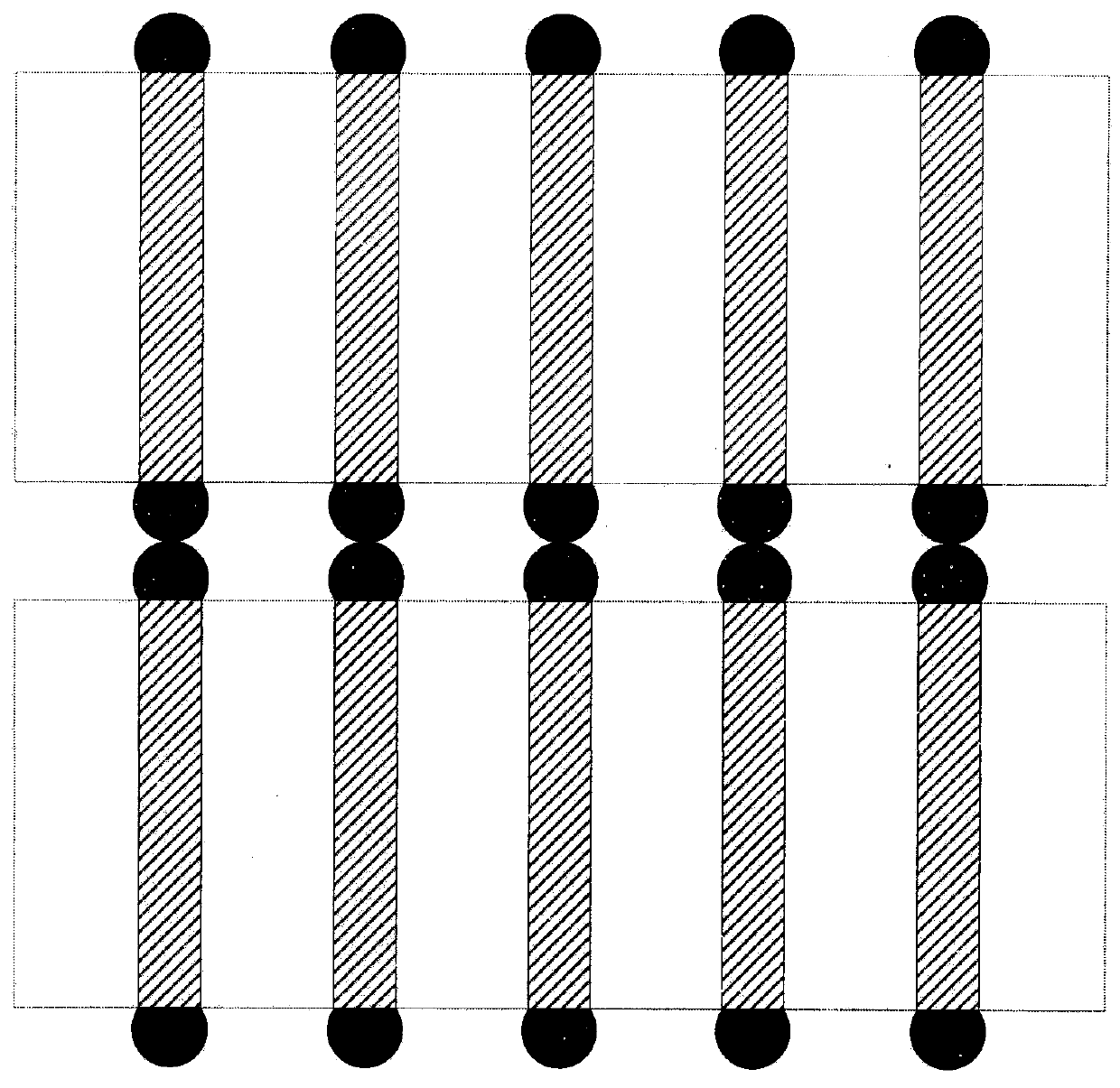

[0021] Individual functional chips form vertical interconnections such as figure 1 As shown, depending on the process, the vertical interconnection can be performed before or after the application circuit is integrated on a single functional chip. First, holes are drilled on the chip by deep reactive ion etching, and then the barrier layer and the adhesion layer are formed respectively. The barrier layer is typically a silicon dioxide material, and the adhesion layer is typically a tungsten material. Next, a seed layer is deposited. The seed layer is generally copper material. After the seed layer is deposited, electroplating can be performed to fill the through holes formed by deep reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com