Preparation method of catalyst for catalytic combustion of volatile organic compounds

A technology of organic compounds and catalytic combustion, which is applied in the direction of combustion methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve problems such as poor stability, low anti-poisoning ability, and low ignition temperature. problems, achieve stable activity, large specific surface area, and overcome the effect of easy sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

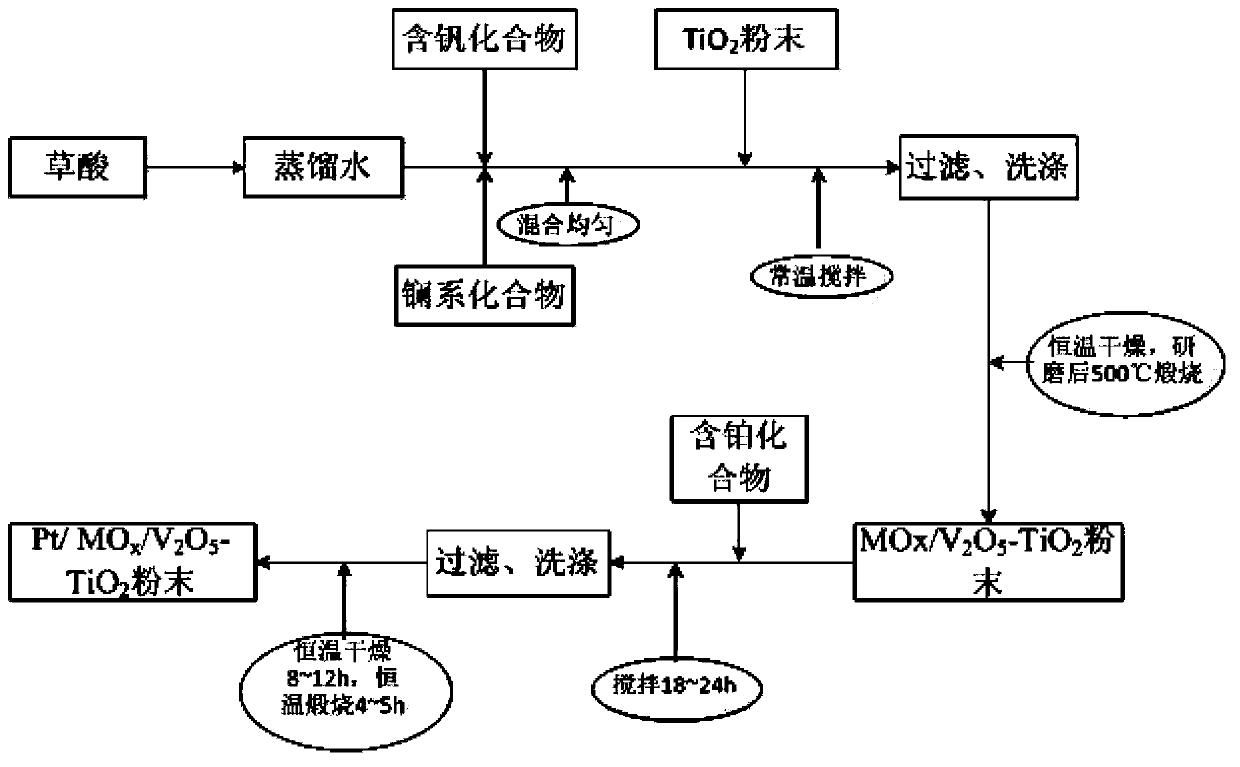

Method used

Image

Examples

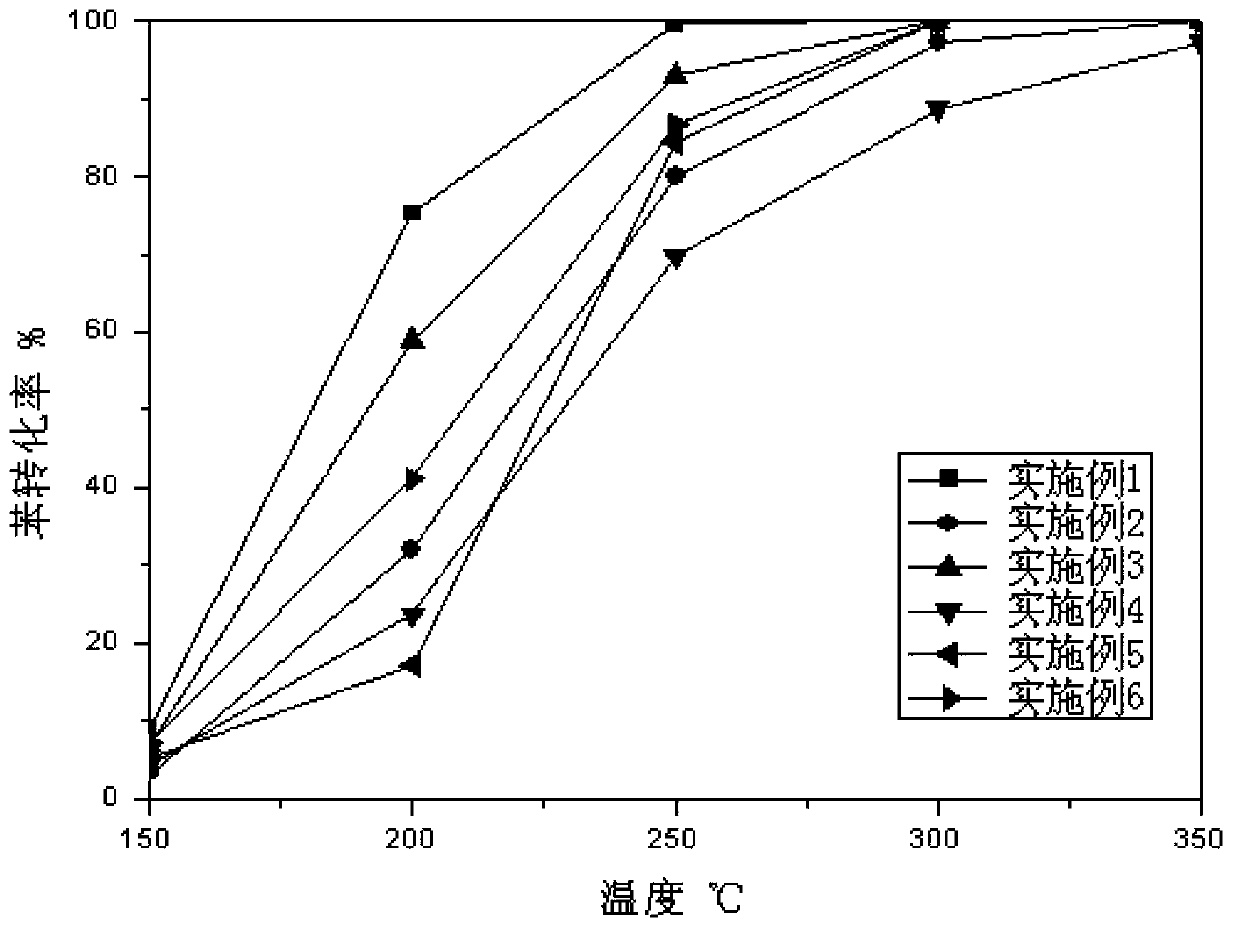

Embodiment 1

[0024] (1) Mix 0.0643g ammonium metavanadate and 0.0252g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 40mL of 1mol / L oxalic acid solution and stirred until completely dissolved.

[0025] (2) Add 1gTiO 2 The powder is dissolved in the solution obtained in (1), stirred at room temperature for 8 hours, filtered and washed 3 times, dried at 70°C for 12 hours, and the powder obtained after grinding is calcined at 500°C for 3 hours to obtain 1% CeO 2 / 5%V 2 o 5 -TiO 2 powder.

[0026] (3) Take 1g of (2) obtained 1%CeO 2 / 5%V 2 o 5 -TiO 2 Powder, dissolved in 40mL deionized water, added 0.5mL tetraammineplatinum nitrate solution (10mg Pt / mL) and stirred for 18h, washed with deionized water for 3 times, the obtained precipitate was dried at 110°C for 10h, then calcined at 400°C for 5h, 0.5%Pt / 1%CeO after grinding 2 / 5%V 2 o 5 -TiO 2 powder.

[0027] Characterized by TEM, the prepared 1%CeO 2 / 5%V 2 o 5 -TiO 2 The powder particle size is between 10~20nm, see figu...

Embodiment 2

[0030] (1) Mix 0.1029g ammonium metavanadate and 0.0126g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 40mL of 1mol / L oxalic acid solution and stirred until completely dissolved.

[0031] (2) Add 1gTiO 2 The powder is dissolved in the solution obtained in (1), stirred at room temperature for 10 hours, dried at 80°C for 10 hours, and the powder obtained after grinding is calcined at 500°C for 3 hours to obtain 1% CeO 2 / 8%V 2 o 5 -TiO 2 powder.

[0032] (3) Take 1g of (2) obtained 1%CeO 2 / 8%V2 o 5 -TiO 2 Powder, dissolved in 40mL deionized water, added 0.5mL tetraammineplatinum nitrate solution (10mg Pt / mL) and stirred for 24h, washed with deionized water for 3 times, the obtained precipitate was dried at 100°C for 12h, then calcined at 400°C for 5h, 0.1%Pt / 1%CeO after grinding 2 / 8%V 2 o 5 -TiO 2 powder.

[0033] Characterized by TEM, the as-prepared 0.1%Pt / 1%CeO 2 / 8%V 2 o 5 -TiO 2 The particle size of powder is between 15~25nm. The specific surface are...

Embodiment 3

[0036] (1) Mix 0.0257g ammonium metavanadate and 0.0066g La(NO 3 ) 3 ·6H 2 O was dissolved in 40mL of 1mol / L oxalic acid solution and stirred until completely dissolved.

[0037] (2) Add 1gTiO 2 The powder is dissolved in the solution obtained in (1), stirred at room temperature for 12 hours, dried at 60°C for 14 hours, and the powder obtained after grinding is calcined at 500°C for 3 hours to obtain 0.5% La 2 o 3 / 2%V 2 o 5 -TiO 2 powder.

[0038] (3) Take 1g of (2) to get 0.5% La 2 o 3 / 2%V 2 o 5 -TiO 2 Powder, dissolved in 40mL deionized water, added 0.1mL tetraammineplatinum nitrate solution (10mg Pt / mL) and stirred for 20h, washed with deionized water for 3 times, the obtained precipitate was dried at 120°C for 8h, then calcined at 400°C for 5h, 0.1Pt / 0.5%La after grinding 2 o 3 / 2%V 2 o 5 -TiO 2 powder.

[0039] Characterized by TEM, the prepared 0.1Pt / 0.5%La 2 o 3 / 2%V 2 o 5 -TiO 2 The particle size is between 10 and 20nm, and the specific s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com