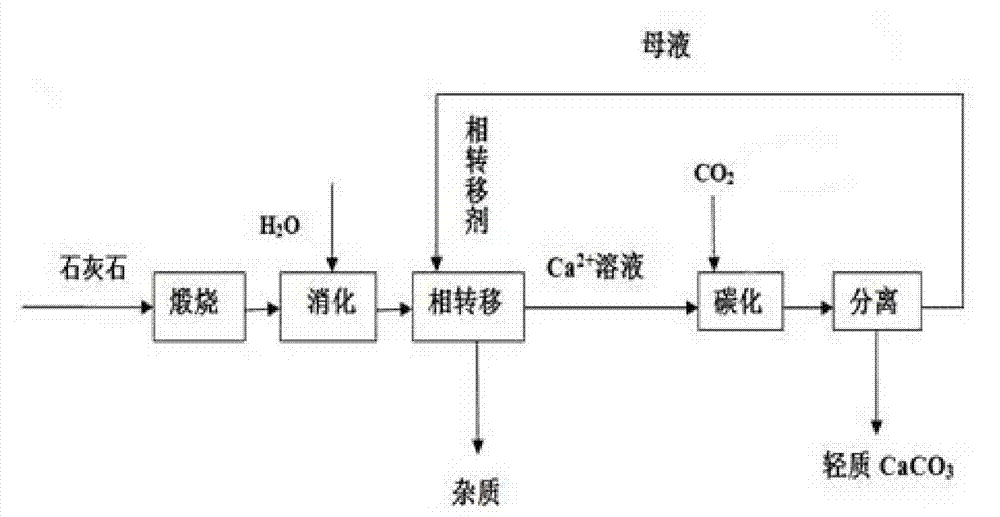

A kind of method that phase transfer-carbonization method prepares light calcium carbonate

A light calcium carbonate, phase transfer technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology for material and surface science, nanotechnology, etc., can solve the problem of long process time, wide particle size distribution and low production efficiency and other problems, to achieve the effect of simple process, narrow particle size distribution and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Add 4.58g of calcined quicklime to 100mL of water to obtain a quicklime coarse slurry with a calcium ion concentration of 0.6mol / L, stir at 300r / min at 25°C for 5min, and then mix according to the amount of phase transfer agent and calcium ion substance. Add the phase transfer agent sodium gluconate at a ratio of 1.5:1, and continue stirring at constant temperature for 40 minutes. After the reaction, filter at room temperature to obtain a soluble calcium ion solution.

[0025] 2. Heat the obtained calcium ion solution to 50°C, add 0.1g of isopropanol as a dispersant, and feed CO at a rate of 40mL / min 2 Gas, the stirring rate is 300r / min, constant temperature stirring reaction for 2h, the pH value of the system drops to 7.6; after the reaction is completed, age at 25°C for 1h, filter and separate the filtrate and filter cake, wash the filter cake with distilled water 2-3 times, Then dry at 60°C for 10 hours to obtain light calcium carbonate. The filtrate is suppleme...

Embodiment 2

[0028] 1. Add 6.12g of quicklime to 100mL of water to obtain a coarse slurry of quicklime, the concentration of calcium ions is 0.8mol / L, stir at room temperature for 5min, and then add phase Transfer agent ammonium citrate, and continue stirring at constant temperature for 20 minutes. After the reaction, filter at room temperature to obtain a soluble calcium ion solution.

[0029] 2. Heat the obtained calcium ion solution to 30°C, add 0.15g of sodium hexametaphosphate, and feed CO at a rate of 40mL / min. 2 gas, the stirring rate is 300r / min, and the reaction is stirred at constant temperature for 2h, and the pH value of the system drops to 7.5. After the reaction, age at 25°C for 1 hour, filter and separate the filtrate and filter cake, wash the filter cake 2-3 times with distilled water, and then dry it at 60°C for 10 hours to obtain light calcium carbonate. The filtrate is supplemented with a phase transfer agent for recycling.

[0030] In this example, the yield of calci...

Embodiment 3

[0032] 1. Add 4.58g of quicklime to 100mL of water to obtain a rough slurry of quicklime, the concentration of calcium ions is 0.6mol / L, stir at room temperature for 5min, and then add phase transfer agent and calcium ion according to the ratio of 2:1 Transfer agent lactic acid, and continue stirring at constant temperature for 30 minutes. After the reaction, filter at room temperature to obtain a soluble calcium ion solution.

[0033] 2. Heat the obtained calcium ion solution to 30°C, add 0.1g of sodium hexametaphosphate, and feed CO at a rate of 40mL / min. 2 Gas, the stirring rate is 300r / min, and the reaction is stirred at constant temperature for 2h, and the pH value of the system drops to 7.6. After the reaction, age at 25°C for 1 hour, filter and separate the filtrate and filter cake, wash the filter cake 2-3 times with distilled water, and then dry it at 60°C for 10 hours to obtain light calcium carbonate. The filtrate is supplemented with a phase transfer agent for re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com