Uses of polybenzoxazine thermosetting resins

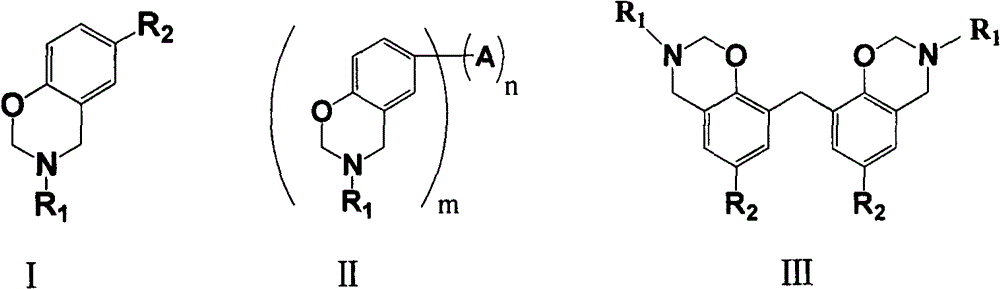

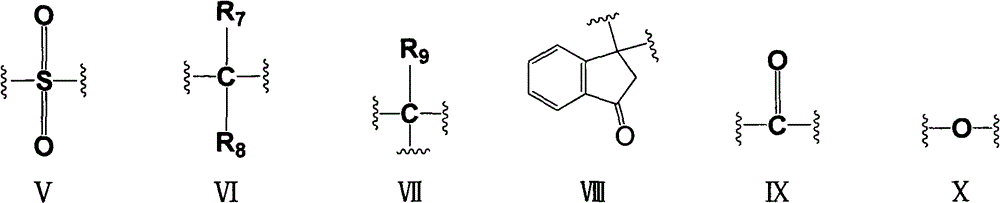

A polybenzoxazine and benzoxazine technology, applied in the direction of anti-corrosion coatings, etc., can solve the problem of difficult to form high-solid thick film coatings, seldom use chemical medium for anti-corrosion, water resistance, adhesion and cathodic disbonding resistance. Sexual problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

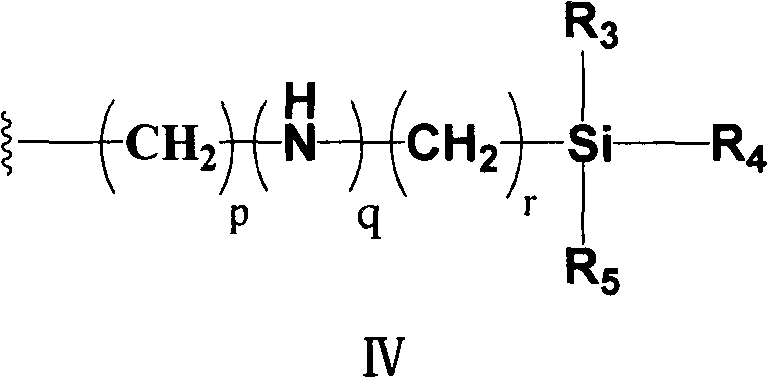

Method used

Image

Examples

Embodiment 1

[0056] With 3-(3-triethoxysilane) n-propyl-6-(trifluoromethyl)-3,4-dihydro-2H-1,3-benzoxazine (TFP-550) (formula I The compound shown in -1) is the precursor, Q235B carbon steel is the substrate, xylene / n-butanol is the solvent, the volume ratio is 7:3, the dip coating method is used, the concentration of the dip coating solution is 200mg / ml, dip coating The pulling rate was 350mm / min, the solvent was removed at 120°C under a vacuum of -0.1MPa for 30min, and the coating was cured at 200°C for 2h. The properties are shown in Table 1.

[0057]

[0058] Table 1

[0059]

Embodiment 2

[0061] The monomer in Example 1 is replaced by 6-methyl-3-(4-(trifluoromethyl)phenyl)-3,4-dihydro-2H-1,3-benzoxazine (MP- TFA) (compound shown in formula I-2), its coating preparation method is identical with embodiment 1, and coating performance is shown in Table 2:

[0062]

[0063] Table 2

[0064]

Embodiment 3

[0066] The monomer in Example 1 is replaced by 3-(1-naphthyl)-3,4-dihydro-2H-1,3-benzoxazine (P-N) (compound shown in formula I-3), which Coating preparation method is identical with embodiment 1, and coating performance is shown in Table 3:

[0067]

[0068] table 3

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com