Preparation method of electroactive benzoxazine-polyaniline intrinsic hybrid oligomer coating

A benzoxazine and electroactive technology, applied in coatings, organic chemistry, anti-corrosion coatings, etc., can solve problems such as process flow design, achieve good application prospects, good processing performance, and solve the effects of poor processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

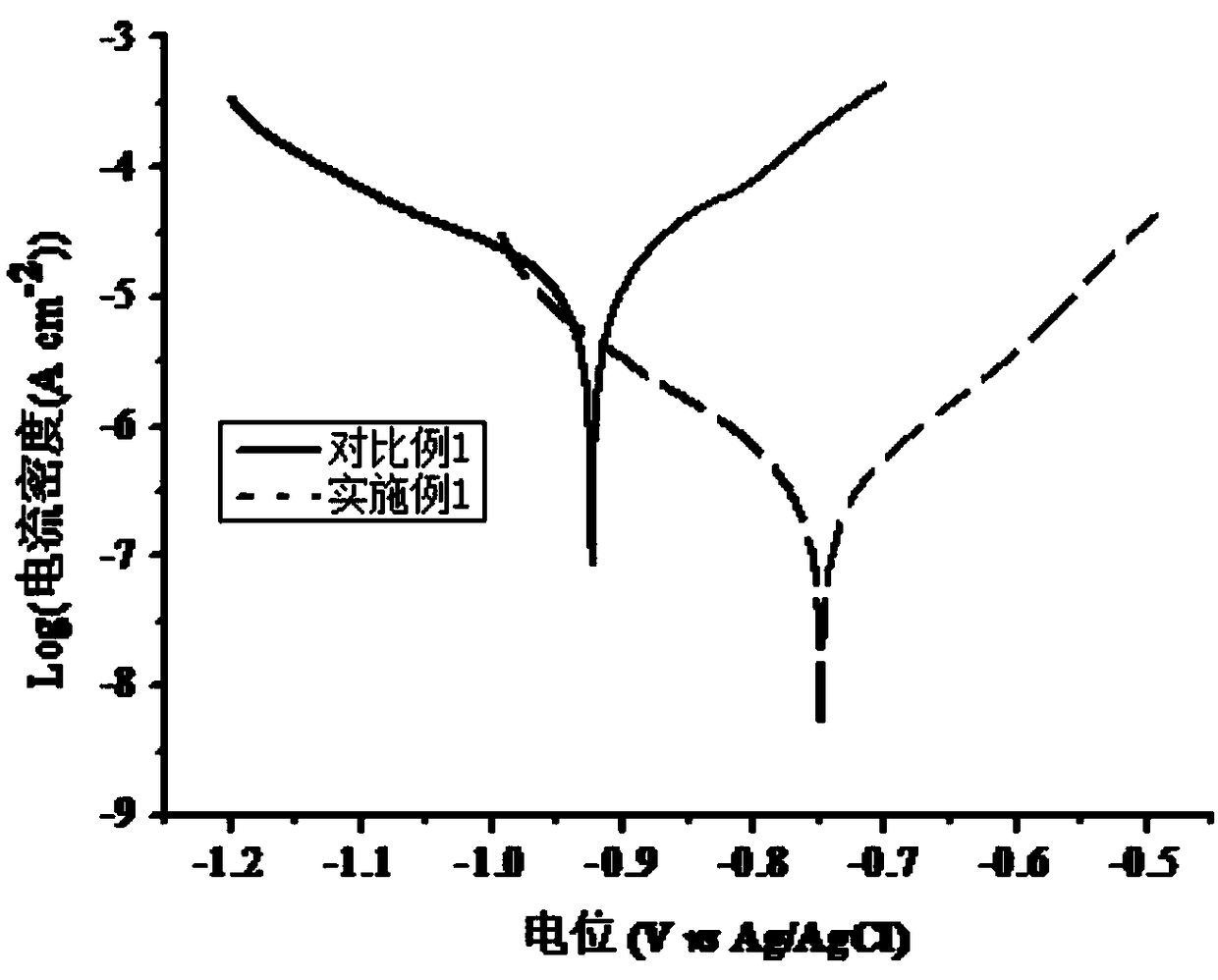

Embodiment 1

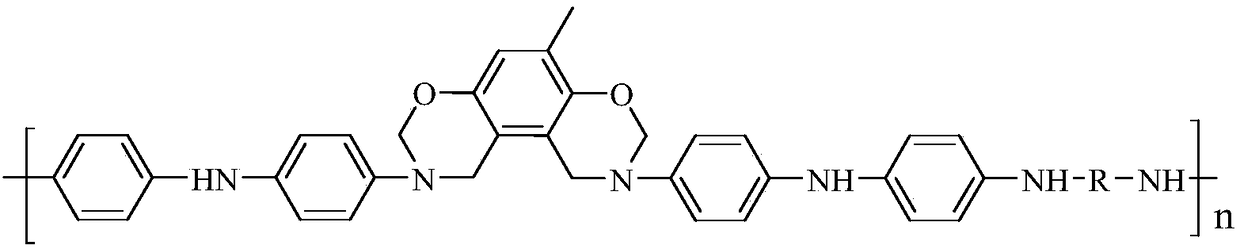

[0058] Weigh 550 parts by weight of structure-type electroactive benzoxazine monomer, 110 parts by weight of p-phenylenediamine and 1000 parts by weight of N-methylpyrrolidone into the reaction kettle, feed nitrogen, and mechanically stir at 300 rpm, Control the system temperature to 30°C. Weigh 6 parts of ammonium persulfate and potassium persulfate mixed catalyst (the weight ratio of ammonium persulfate and potassium persulfate is 1:9). The mixed catalyst was added to 10 parts of hydrochloric acid-water solution with a concentration of 0.8 mol / liter. After the catalyst was completely dissolved, the catalyst solution was added dropwise to the dispersion in the reactor within 1 hour. After the catalyst solution was added dropwise, the reaction temperature was kept constant at 30° C., and the reaction was continuously stirred for 10 hours, and then filtered to obtain a gray-black powder. The gray-black powder was washed three times with water, acetone and absolute ethanol, and...

Embodiment 2

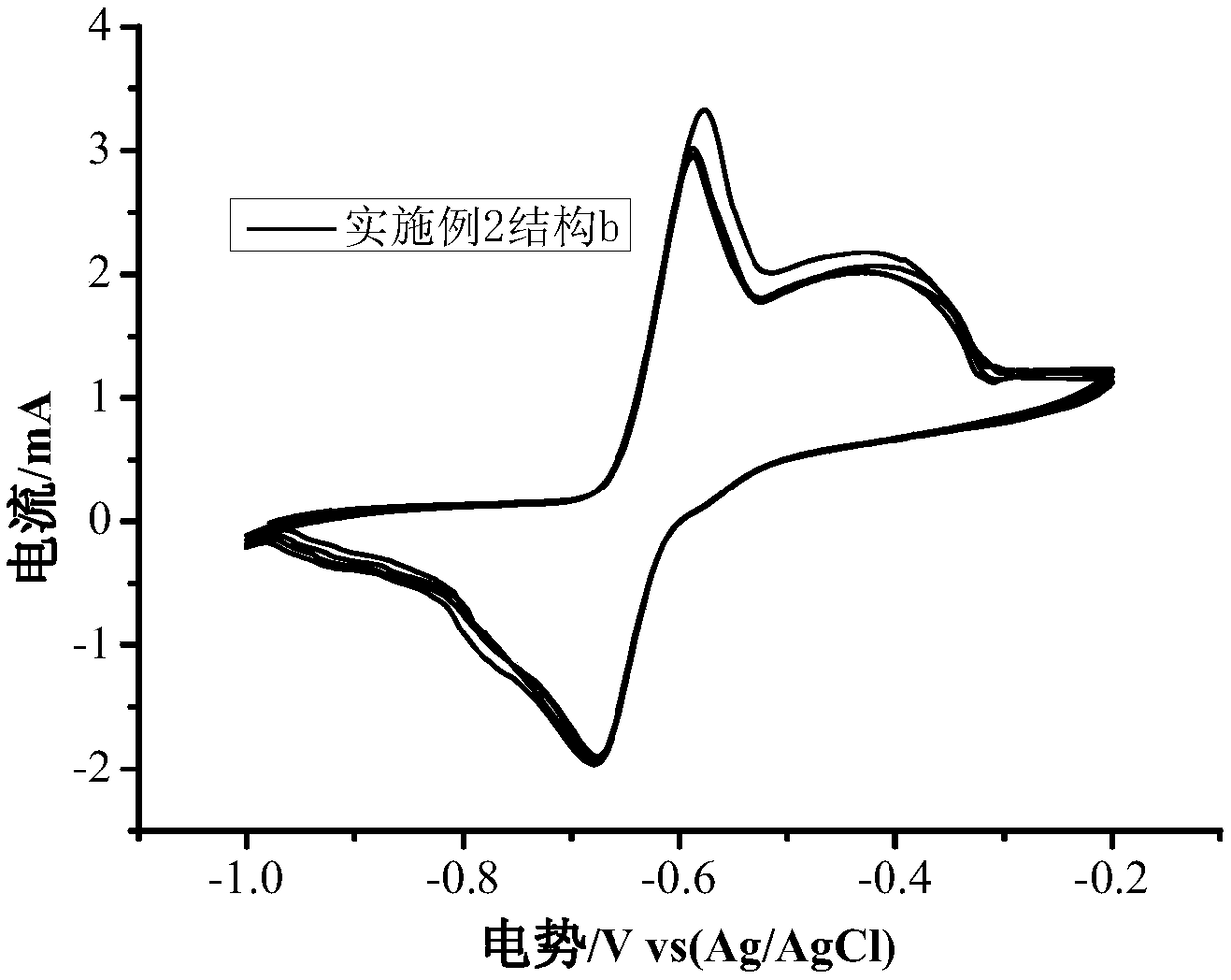

[0066] Weigh 590 parts by weight of structure type II electroactive benzoxazine monomer, 190 parts by weight of biphenyldiamine and 1200 parts by weight of N-N-dimethylformamide and add them to the reaction kettle, feed nitrogen, and mechanically Stir and control the system temperature to 40°C. Weigh 40 parts of ammonium persulfate catalyst. The mixed catalyst was added to 60 parts of hydrochloric acid-water solution with a concentration of 0.5 mol / liter. After the catalyst was completely dissolved, the catalyst solution was added dropwise to the dispersion in the reactor within 2 hours. After the catalyst solution was added dropwise, the reaction temperature was kept constant at 40° C., the reaction was continued to stir for 6 hours, and filtered to obtain a gray-black powder. The gray-black powder was washed 6 times with water, acetone and absolute ethanol, and dried in vacuum at 100°C for 12 hours to obtain black electroactive benzoxazine-polyaniline intrinsic hybrid oligo...

Embodiment 3

[0070] Weigh 610 parts by weight of structure III type electroactive benzoxazine monomer, 160 parts by weight of benzidine diamine and 1400 parts by weight of dimethyl sulfoxide into the reaction kettle, feed nitrogen, and mechanically stir at 600 rpm, Control the system temperature to 20°C. Weigh 20 parts of ammonium persulfate and sodium persulfate mixed catalyst (the weight ratio of ammonium persulfate and sodium persulfate is 5:5). The mixed catalyst was added to 40 parts of hydrochloric acid-water solution with a concentration of 0.8 mol / liter. After the catalyst was completely solvent, the catalyst solution was added dropwise to the dispersion in the reactor for 1.5 hours. After the catalyst solution was added dropwise, the reaction temperature was kept constant at 20° C., the reaction was continuously stirred for 12 hours, and the reaction was filtered to obtain a gray-black powder. The gray-black powder was washed 4 times with water, acetone and absolute ethanol in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com