Water soluble salt microcapsule wrapped by polybenzoxazine resin and preparation method thereof

A technology of water-soluble salt and benzoxazine, which is applied in the field of water-soluble salt microcapsules coated with benzoxazine resin and its preparation, can solve the problems of large particle size and complicated process, and achieve low cost and excellent preparation process. Simple, good heat and corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In 100ml cyclohexane, add 10g surfactant Span-80 (Span-80) to form oil phase solution A;

[0040] Add 3 g of water-soluble salt potassium acetate to 5 g of deionized water to form aqueous solution B;

[0041] In 5g deionized water, add 3g resorcinol and 5g acetaldehyde to form aqueous phase solution C,

[0042] Mix solutions B and C evenly and add them to solution A to form a stable W / O emulsion D at a stirring rate of 100-5000r / min;

[0043] Add 2 g of aniline solution dropwise to emulsion D, heat to 50°C, and react for 30 minutes;

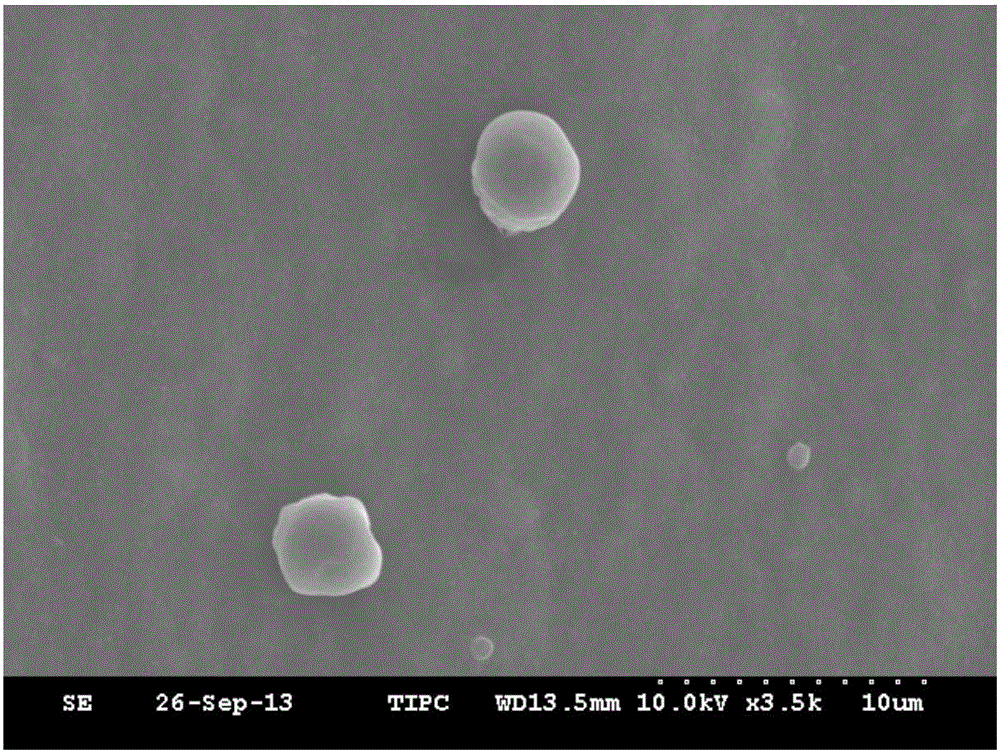

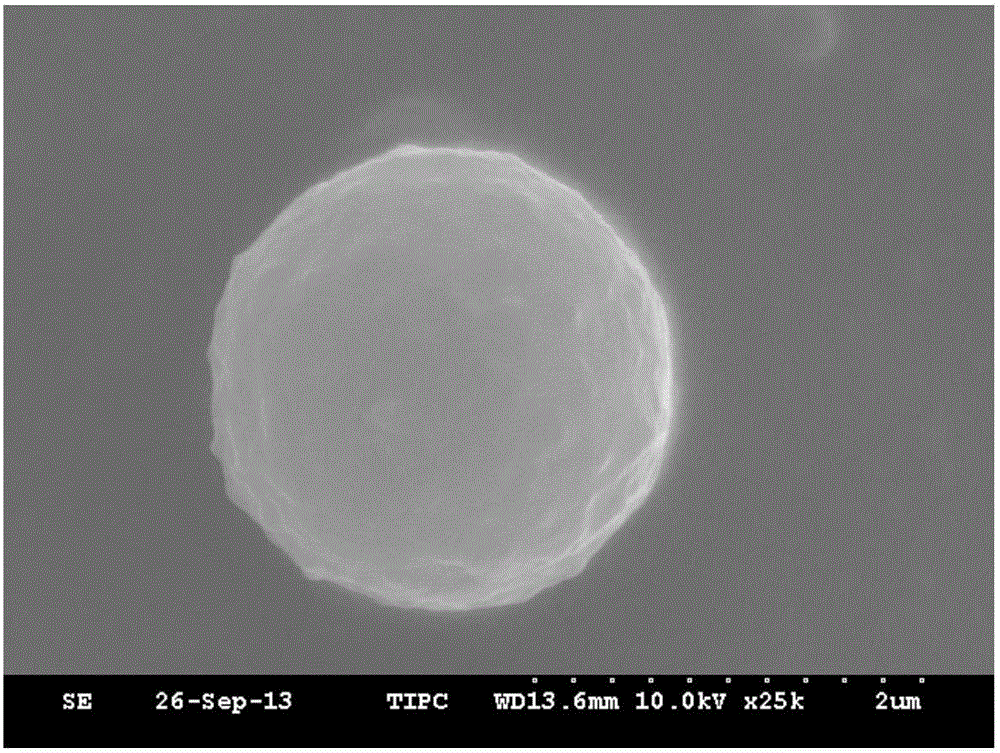

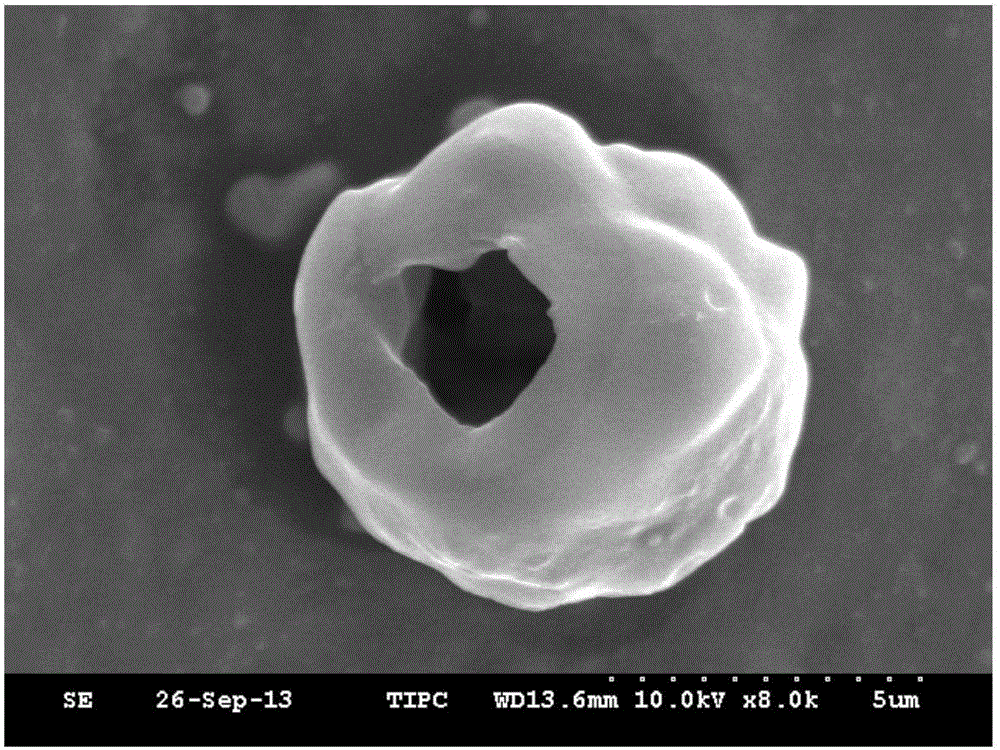

[0044] The complete reaction solution is filtered to separate the microcapsules; washed with petroleum ether organic solvent, suction filtered and dried to form potassium acetate microcapsules coated with benzoxazine resin. figure 1 , 2 , 3 are respectively 3500 times, 25000 times, and 8000 times of SEM figures for the magnification of the microcapsules prepared in Example 1, from figure 1 It can be seen that the microcapsules have goo...

Embodiment 2

[0048] In 90ml cyclohexane, add 8g surfactant Span-80 (Span-80) to form oil phase solution A;

[0049] Add 2g of water-soluble salt sodium acetate to 5g of deionized water to form aqueous solution B;

[0050] In 6g deionized water, add 4g phenol and 6g butyraldehyde to form aqueous solution C,

[0051] Mix solutions B and C evenly and add them to solution A to form a stable W / O emulsion D at a stirring speed of 1500r / min;

[0052] Add 1 g of ethylenediamine solution dropwise to emulsion D, and heat to 55°C for 45 minutes;

[0053] The complete reaction solution is filtered to separate the microcapsules; washed with petroleum ether organic solvent, suction filtered and dried to form sodium acetate microcapsules coated with benzoxazine resin.

Embodiment 3

[0055] Add 8g of surfactant Span-80 (Span-80) to 90ml petroleum ether to form oil phase solution A;

[0056] Add 2g of water-soluble sodium sulfate to 5g of deionized water to form aqueous solution B;

[0057] In 6g deionized water, add 4g resorcinol and 6g formaldehyde to form aqueous phase solution C,

[0058] Mix solutions B and C evenly and add them to solution A to form a stable W / O emulsion D at a stirring speed of 1000r / min;

[0059] Add 2g of aniline solution dropwise to emulsion D, heat to 60°C, and react for 60min;

[0060] The complete reaction solution is filtered to separate the microcapsules; washed with n-hexane organic solvent, suction filtered and dried to form sodium sulfate microcapsules coated with benzoxazine resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com