Colorful thermoplastic polyolefin (TPO) waterproof coil and preparation method thereof

A technology of thermoplastic polyolefin and waterproof membrane, which is applied in chemical instruments and methods, roofing and lamination using flexible materials, etc., can solve the problems of single color and insufficient weather resistance of TPO waterproof membrane, and achieve excellent waterproof effect, Guaranteed weather resistance and color retention performance, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

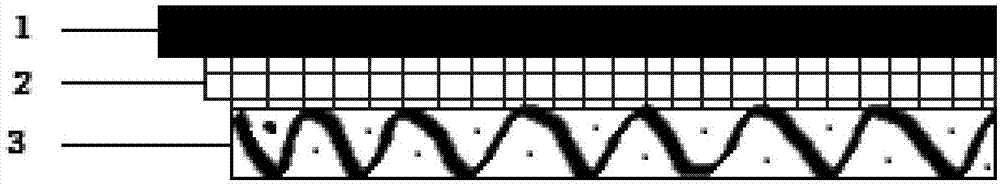

[0038] Use polyester grid cloth as the middle reinforcement layer, the warp fineness of the mesh cloth is 1000D, the weft fineness is 1300D, and the total thickness of the product is 1.50mm;

[0039] The colored layer on the upper surface is yellow in color and has a thickness of 0.70mm, and the colored layer on the lower surface is gray in color and has a thickness of 0.70mm.

[0040] The components and parts by weight of each layer are:

[0041]

Colored TPO layer on the upper surface

Colored TPO layer on the lower surface

TPO

100

100

flame retardant

10

10

filler

10

15

Dispersant

1

1

1

1

0.75

0

light stabilizer

0.75

0

Toner

3

2

[0042] Described TPO resin is the CA10A resin of the Hifax brand of Basel full polymerization;

[0043] Described flame retardant adopts stearic acid surface-modified magnesium hyd...

Embodiment 2

[0057] Use polyester grid cloth as the middle reinforcement layer, the warp fineness of the mesh cloth is 1000D, the weft fineness is 1300D, and the total thickness is 1.20mm;

[0058] The colored layer on the upper surface is blue in color and has a thickness of 0.55mm, and the colored layer on the lower surface is gray in color and has a thickness of 0.55mm.

[0059] The components and weight fractions of each layer are:

[0060]

Colored TPO layer on the upper surface

Colored TPO layer on the lower surface

TPO

100

100

flame retardant

10

10

filler

5

10

Dispersant

0.75

0.75

1

1

0.75

0

light stabilizer

0.75

0

[0061] Toner

2.5

2

[0062] Described TPO resin is the CA10A resin of the Hifax brand of Basel full polymerization;

[0063] Described flame retardant adopts stearic acid surface-modified mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com