Preparation method of composite flocculant

A composite flocculant, temperature control technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of low dosage, and achieve the effect of less sludge production, large molecular weight, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

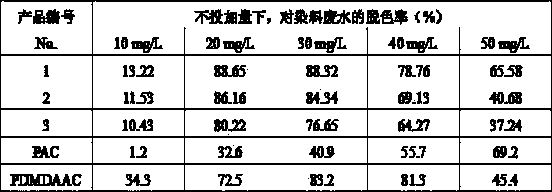

Examples

Embodiment 1

[0019] (1) Take 24mL of liquid paraffin in a 250mL four-necked round bottom flask with a stirrer and a reflux condenser, place the flask in an ice-water bath, and control the temperature at 8°C , And feed nitrogen into the flask for 15min (the flow rate is 0.5m 3 / h), then weigh 6.02 g of ethylenediamine into the round bottom flask (the mass ratio of ethylenediamine to liquid paraffin is 1:3), turn on the cooling water of the reflux condenser, and stir at G value of 150 S -1 While stirring, the temperature was raised to 25 °C, and 18.56 g of epichlorohydrin (the molar ratio of epichlorohydrin to ethylenediamine was 2:1) was slowly added dropwise with a separatory funnel for addition reaction, and the dropping time was 2.5 hours. Stirring was continued for 60 minutes after the addition was complete; the temperature was then lowered to 15°C. According to the molar ratio of trimethylamine and epichlorohydrin as 1:1.5, add a trimethylamine aqueous solution crosslinking agent with...

Embodiment 2

[0024] (1) Take 24mL of liquid paraffin in a 250mL four-necked round bottom flask with a stirrer and a reflux condenser, place the flask in an ice-water bath, and control the temperature at 5°C , And feed nitrogen into the flask for 15 min, then weigh 6.02 g of ethylenediamine and add it to the round-bottomed flask, open the cooling water of the reflux condenser, and stir at a G value of 200 S -1 While stirring, the temperature was raised to 22 ° C, and 18.56 g of epichlorohydrin (the molar ratio of epichlorohydrin to ethylenediamine was 2:1) was slowly added dropwise with a separatory funnel for addition reaction, and the dropping time was 3 hours. Stirring was continued for 60 minutes after the addition was complete; the temperature was then lowered to 15°C. Add 33% trimethylamine aqueous solution crosslinking agent according to the molar ratio of trimethylamine and epichlorohydrin as 1:1.5; make the temperature rise to 90°C again, react at constant temperature for 5 hours, ...

Embodiment 3

[0029] (1) Take 24mL of liquid paraffin in a 250mL four-neck round bottom flask with a stirrer and a reflux condenser, place the flask in an ice-water bath, and control the temperature at 0°C , And feed nitrogen into the flask for 15 min, then weigh 6.02 g of ethylenediamine and add it to the round-bottomed flask, open the cooling water of the reflux condenser, and stir at a G value of 250 S -1 While stirring, the temperature was raised to 20 °C, and 18.56 g of epichlorohydrin (the molar ratio of epichlorohydrin to ethylenediamine was 2:1) was slowly added dropwise with a separatory funnel for addition reaction, and the dropping time was 2 hours. Stirring was continued for 60 minutes after the addition was complete; the temperature was then lowered to 15°C. According to the molar ratio of trimethylamine and epichlorohydrin as 1:1.5, add 33% trimethylamine aqueous solution cross-linking agent, raise the temperature to 88°C again, react at constant temperature for 5 hours, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com