Preparation method of triphenylethylene derivative luminescent film

A technology of light-emitting film and triphenylene, which is applied in the manufacture of semiconductor/solid-state devices, electrolytic coatings, electrophoretic plating, etc., can solve the problems of difficulty in preparing light-emitting films with high performance, and achieve high light-emitting efficiency, simple operation and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

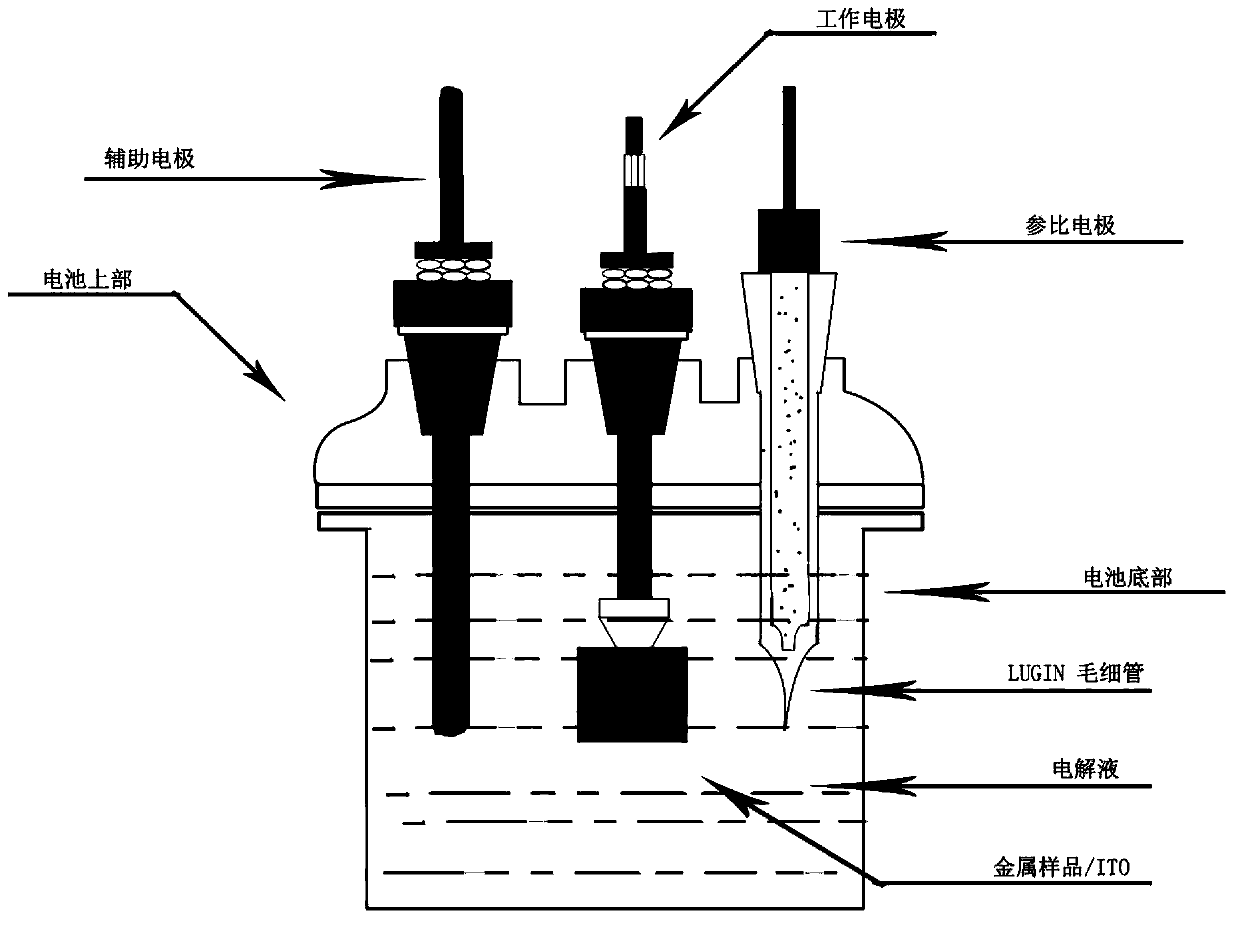

[0027] The electrochemical preparation method of the luminescent thin film of the present invention is completed in the electrolytic cell, and the structural schematic diagram of the electrolytic cell is as follows: figure 1 As shown, the electrolytic cell is composed of a working electrode, an auxiliary electrode, a reference electrode, and an electrolyte solution.

[0028] The working electrode used is a redox inert electrode, which can work stably in the region of the measured potential. The electrode materials used can be metal electrodes such as gold, platinum, lead, and titanium, or non-metal electrodes such as graphite and glassy carbon, and ITO translucent optical electrodes.

[0029] The main function of the auxiliary electrode is to form a loop with the working electrode, so as long as it is an electrode that is redox inert and does not react with the medium in the solution, such as platinum, lead, gold, titanium, etc., this experiment uses a titanium electrode as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com