A method for measuring acetylcholinesterase activity with a dual-function quantum dot sensing system

An acetylcholinesterase, dual-function technology, applied in the field of analytical chemistry, can solve the problems of unfavorable quantum dot material characteristics, limited space for sensitivity improvement, complicated reaction steps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Synthesis of NaHTe precursor: 10mL round bottom flask was connected with sealing water through a small needle and rubber tube, and 0.2gNaBH 4 and 0.16gTe powder were added to the sealed flask, and N 2 After that, inject 3.0 mL of deoxygenated distilled water under ice bath, and react for 6 hours, and the obtained clear liquid is the Te source for the next step of quantum dot synthesis;

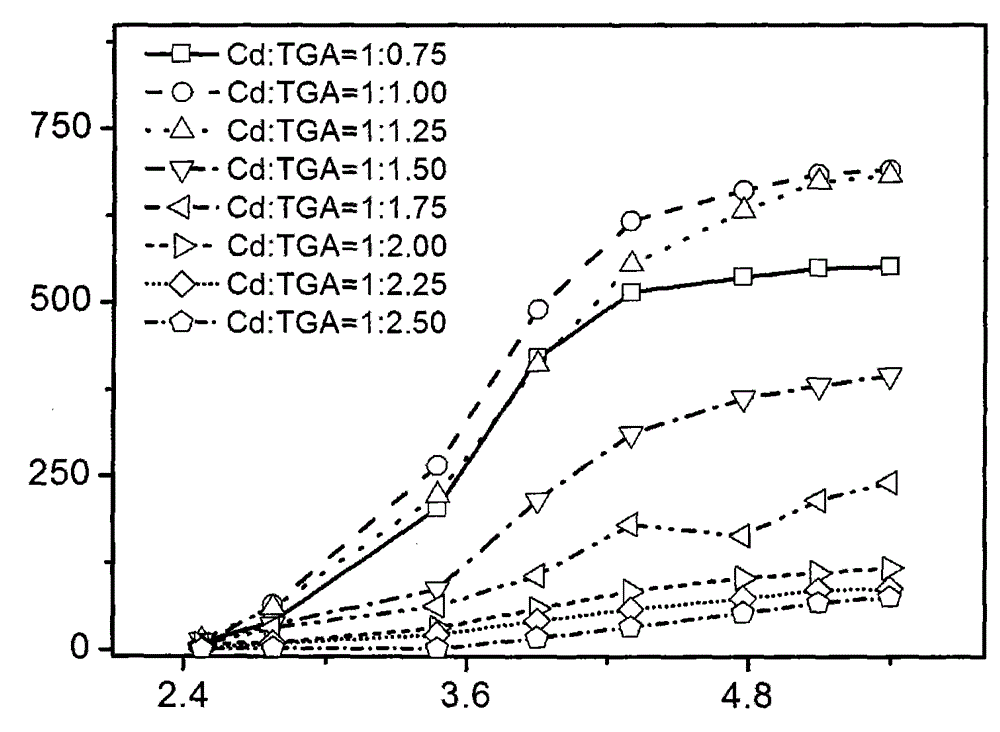

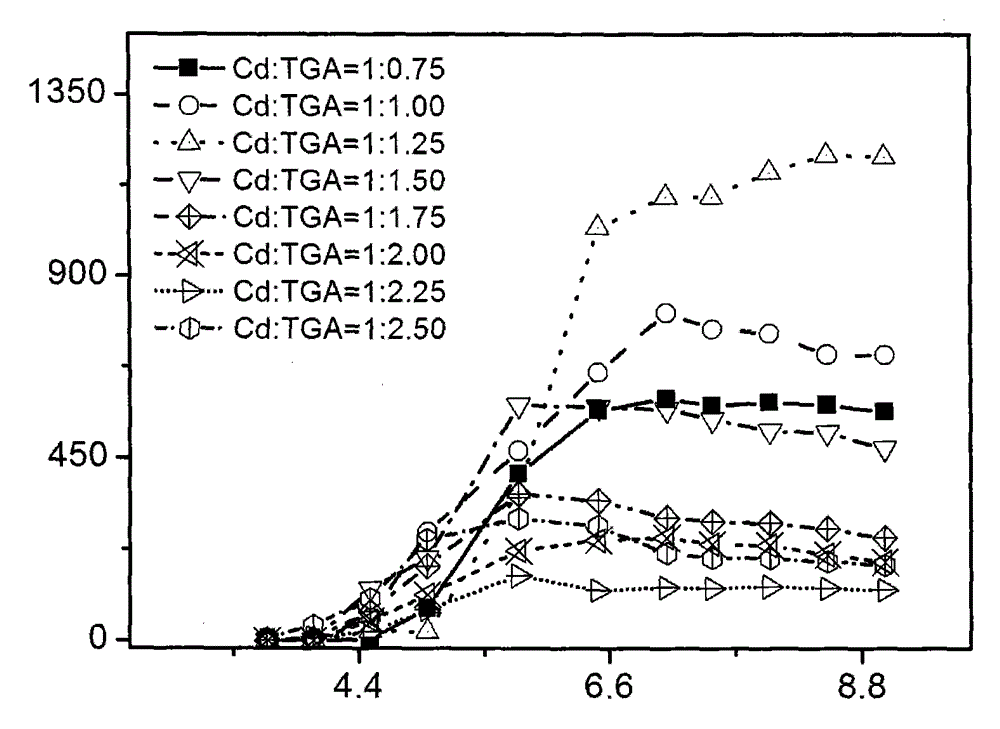

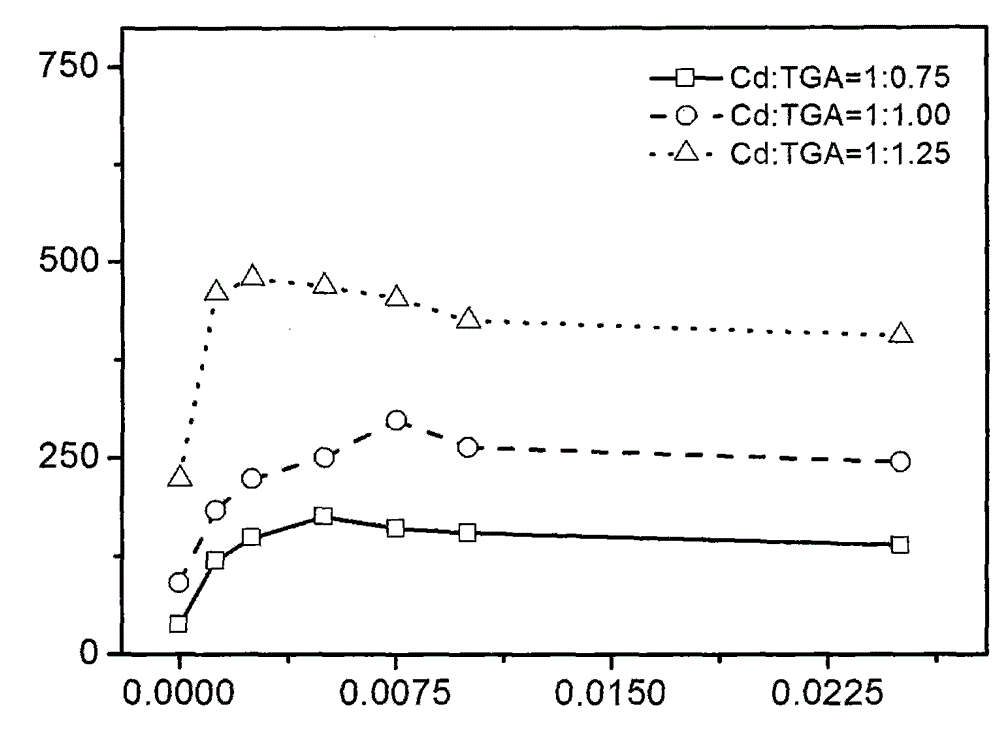

[0031] Bifunctional TGA-CdTe quantum dot synthesis: weigh 0.23gCdCl 2 After dissolving in 100mL distilled water, add TGA, Cd 2+ The molar ratio between TGA and TGA is 1:0.75, the pH of the solution is adjusted to 11.2 with 0.1M NaOH, and N 2 30min, quickly inject the newly synthesized NaHTe solution, Cd 2+ :HTe - The molar ratio is 1:0.5, the solution in N 2 Reflux at 100°C for 4hr under protection. The obtained quantum dots were filtered through a 0.45 μm filter membrane, and passed through N 2 save.

[0032] Prepare 0.2M NaAC-HAC with different pH buffers, the pHs are 3.5, 4.0...

Embodiment 2

[0037] Synthesis of NaHTe precursor: 10mL round bottom flask was connected with sealing water through a small needle and rubber tube, and 0.2gNaBH 4 and 0.16gTe powder were added to the sealed flask, and N 2 After that, inject 3.0 mL of deoxygenated distilled water under ice bath, and react for 6 hours, and the obtained clear liquid is the Te source for the next step of quantum dot synthesis;

[0038] Bifunctional TGA-CdTe quantum dot synthesis: weigh 0.23gCdCl 2 After dissolving in 100mL distilled water, add TGA, Cd 2+ The molar ratio between TGA and TGA was 1:1.25, and the pH of the solution was adjusted to 11.2 using 0.1M NaOH, and N 2 30min, quickly inject the newly synthesized NaHTe solution, Cd 2+ :HTe - The molar ratio is 1:0.5, the solution in N 2 Reflux at 100°C for 4hr under protection. The obtained quantum dots were filtered through a 0.45 μm filter membrane, and passed through N 2 save.

[0039] Prepare 0.2M NaAC-HAC with different pH buffers, the pHs are 3...

Embodiment 3

[0044] Synthesis of NaHTe precursor: 10mL round bottom flask was connected with sealing water through a small needle and rubber tube, and 0.2gNaBH 4 and 0.16gTe powder were added to the sealed flask, and N 2 After that, inject 3.0 mL of deoxygenated distilled water under ice bath, and react for 6 hours, and the obtained clear liquid is the Te source for the next step of quantum dot synthesis;

[0045] Bifunctional TGA-CdTe quantum dot synthesis: weigh 0.23gCdCl 2 After dissolving in 100mL distilled water, add TGA, Cd 2+ The molar ratio between TGA and TGA is 1:1.75, use 0.1M NaOH to adjust the pH of the solution to 11.2, pass N 2 30min, quickly inject the newly synthesized NaHTe solution, Cd 2+ :HTe - The molar ratio is 1:0.5, the solution in N 2 Reflux at 100°C for 4hr under protection. The obtained quantum dots were filtered through a 0.45 μm filter membrane and passed through N 2 save.

[0046] Prepare 0.2M NaAC-HAC with different pH buffers, the pHs are 3.5, 4.0, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com